Pre-curing solvent-free compound machine

A solvent-free laminating machine and pre-curing technology, applied in the field of laminating machines, can solve the problems of toxicity, fluctuation of substrate tension, and high energy consumption of drying devices, and achieve the effects of reducing energy consumption, avoiding downtime and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

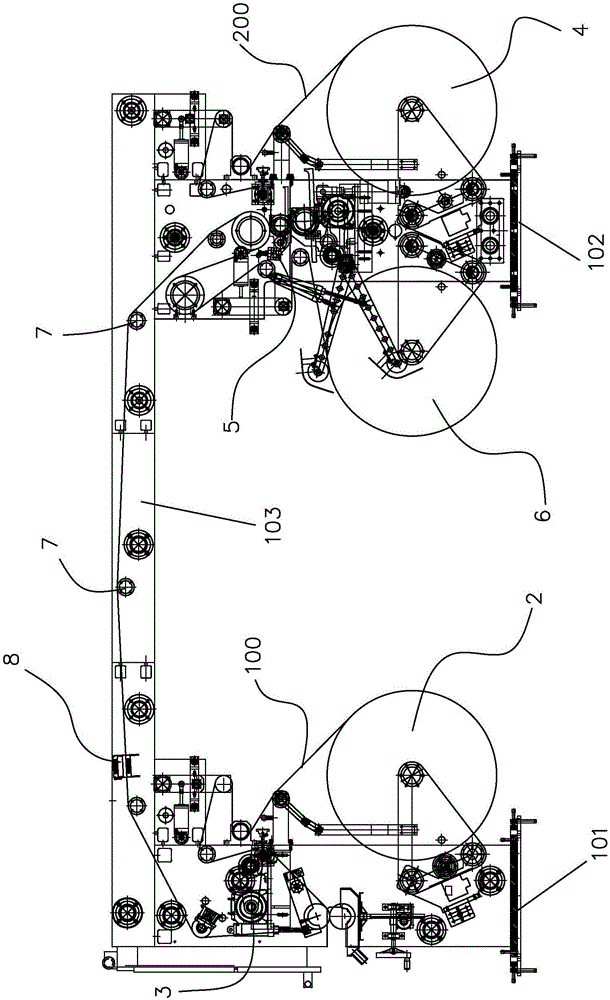

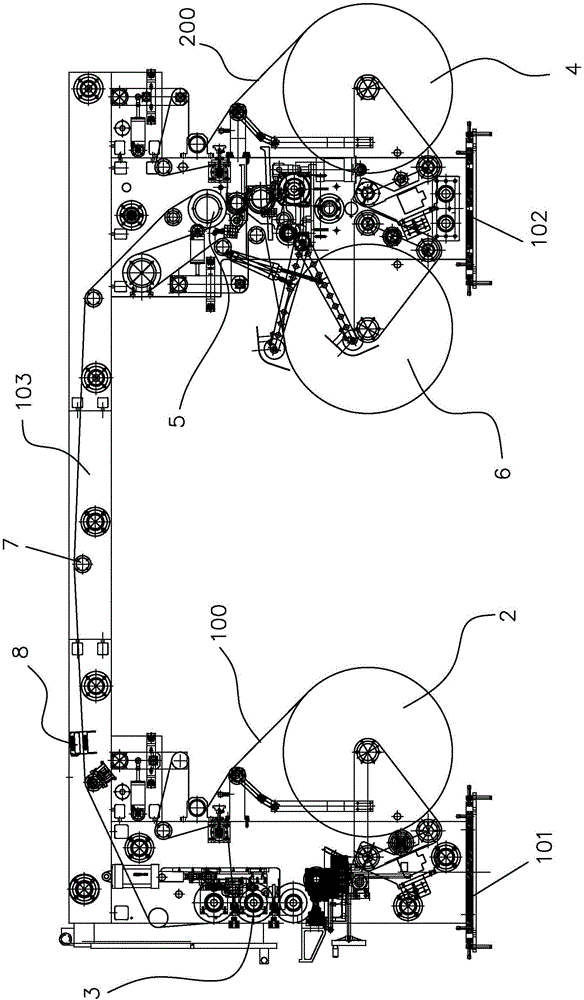

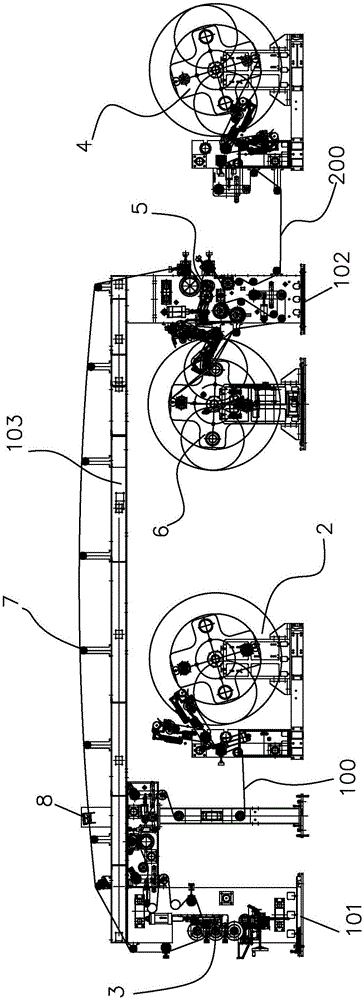

[0029] Such as Figure 1 to Figure 6 As shown, a pre-curing solvent-free laminating machine in this embodiment includes: a first frame 101, a second frame 102, a beam 103, a first unwinding unit 2, a coating unit 3, and a second unwinding Unit 4, composite unit 5, winding unit 6, guide roller set 7 and pre-curing drying device 8; the beam 103 is erected on the first frame 101 and the second frame 102; the first unwinding The unit 2 is arranged on the first frame 101 for output of the substrate A100; the coating unit 3 is arranged on the first frame 101 and is located at the output end of the first unwinding unit 2, and is used for placing The substrate A100 output by the roll unit 2 is coated with a compounding agent; the second unwinding unit 4 is set on the second frame 102 for outputting the substrate B200; the compound unit 5 is set on the second frame 102, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com