a kind of uo 2 Method for sintering pellets horizontally in sintering furnace

A sintering furnace and pellet technology, applied in the direction of uranium oxide/hydroxide, etc., to achieve the effects of reducing pollution waste, stabilizing the production process, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

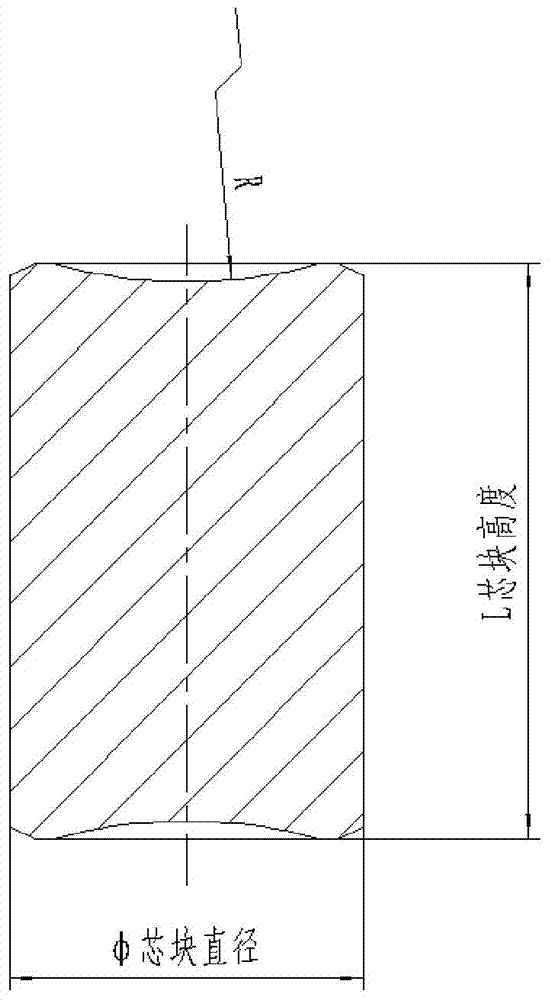

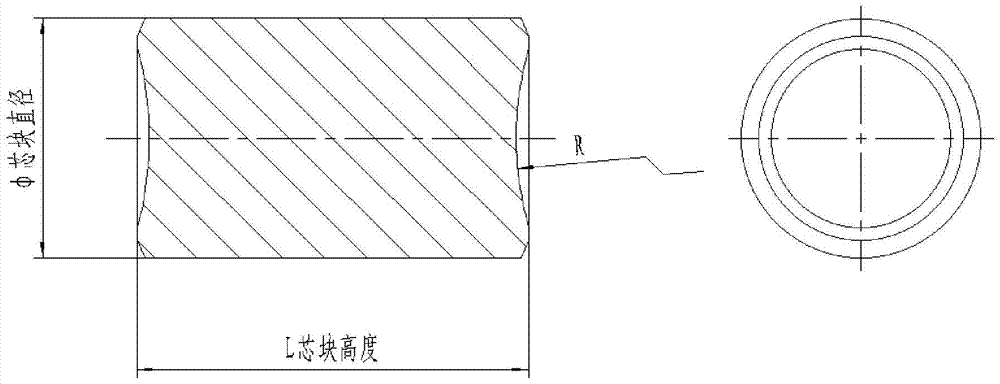

[0031] A kind of UO 2 The method for sintering pellets horizontally in a sintering furnace is characterized in that it comprises the following steps:

[0032] (1) Determine the molybdenum boat and V-shaped plate

[0033] The molybdenum boat of the original pusher boat furnace is still used for horizontal sintering. The length of the molybdenum boat is 260mm and the width is 134mm;

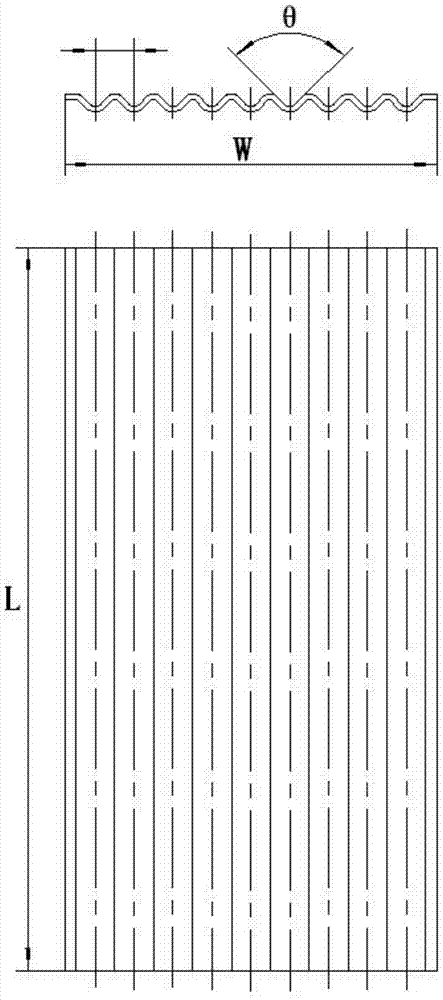

[0034] In order to meet the requirements of horizontal sintered pellet placement, a molybdenum V-shaped plate is placed under the molybdenum boat, such as image 3 As shown, a molybdenum V-shaped plate is placed on the lower part of the molybdenum boat, and the V-shaped plate is closely attached to the molybdenum boat, and its thickness is 2mm; in this embodiment, the material of the V-shaped plate is molybdenum-lanthanum alloy, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com