Automatic sauce filling machine

A filling machine and sauce technology, applied in packaging, solid materials, bottle filling, etc., can solve problems such as failure to meet product quality requirements, imbalance of solid-liquid ratio, solid-liquid mixing with gaps, etc., to improve labor production efficiency, High efficiency and running speed, easy sanitation cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

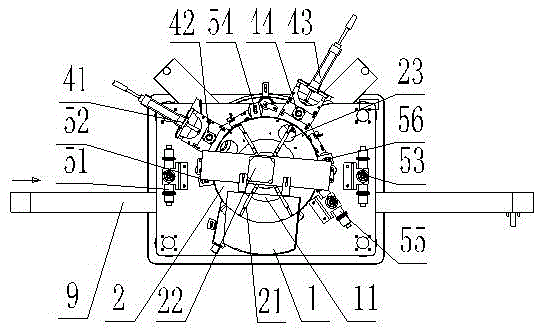

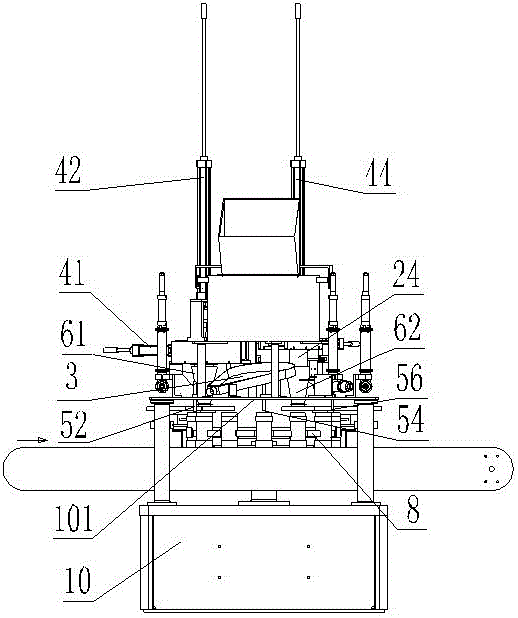

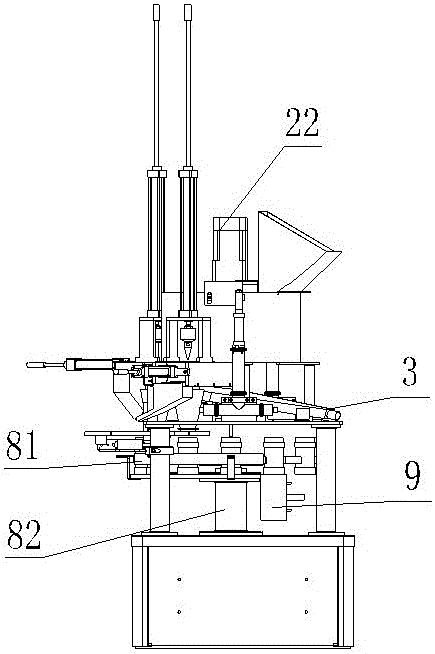

[0024] An automatic sauce filling machine, comprising a hopper 1, a silo 2, a material liquid recovery device 3, a material injection device, an oil injection device, a turntable 8, a conveyor belt 9, a shelf 10 and a control system, and the shelf 10 is fixed on the ground On the shelf, a platform 101 is fixed, on which a silo 2 is installed, and a hopper 1 is installed on the upper part of the silo 2, and the material liquid recovery device 3, the injection device, and the oil injection device are arranged on the platform 101, which is characterized in that , the injection device is provided with two sets of cylinders, an air hammer, a measuring cup and a funnel, the oil injection device is provided with three sets of oil cylinders and an oil injection port, a stirring device 21 is arranged in the stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com