High magnetic permeability manganese-zinc ferrite material for automotive electronics and preparation method thereof

A technology of magnetic permeability of manganese-zinc and ferrite materials, applied in the direction of inorganic material magnetism, etc., can solve the problems of unstable temperature change performance of devices, unsatisfactory temperature stability of magnetic permeability, etc., and achieve good stability and consistency. Good performance and stable material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

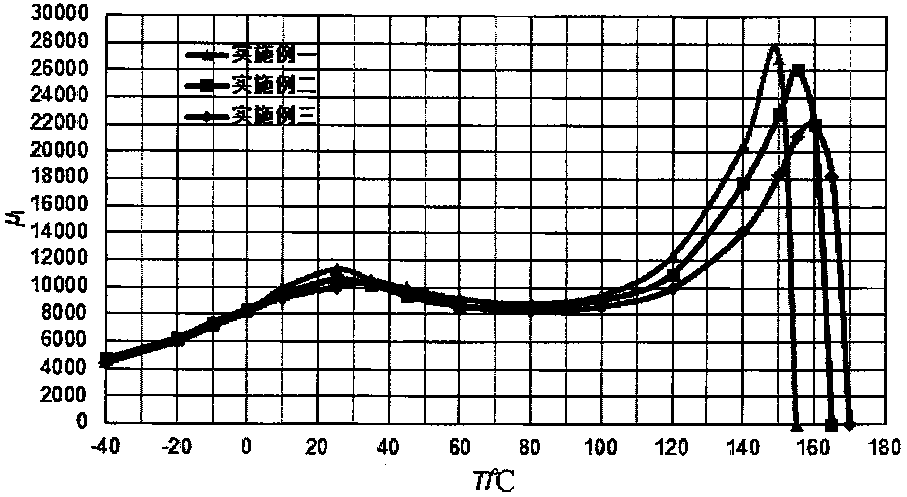

Embodiment 1

[0045] The preparation method of the first high magnetic permeability MnZn ferrite material for automotive electronics, the specific steps are as follows:

[0046] 1) Ingredients: the main component is 52.74mol% Fe 2 o 3 , 20.29mol% ZnO, and the rest are MnO; calculate the quality of the required raw materials according to the total set mass, the corresponding molar ratio and the purity of each raw material, and MnO will be converted into MnO 3 o 4 The quality of each raw material is weighed, and then 0.08wt% CuO auxiliary material is weighed according to the total set mass;

[0047] 2) Mixing: Use a vibration mill to mix the raw and auxiliary materials in step 1) for 30 minutes;

[0048] 3) Pre-sintering: Pre-sinter the raw materials mixed in step 2) in a box furnace or a rotary kiln at 880°C for 2 hours;

[0049] 4) Pulverization: Add 0.05wt% CaCO to the calcined material produced in step 3) 3 , 0.02wt%Ta 2 o 5 , 0.02wt%In 2 o 3 , 0.01wt%Bi 2 o 3 After the auxilia...

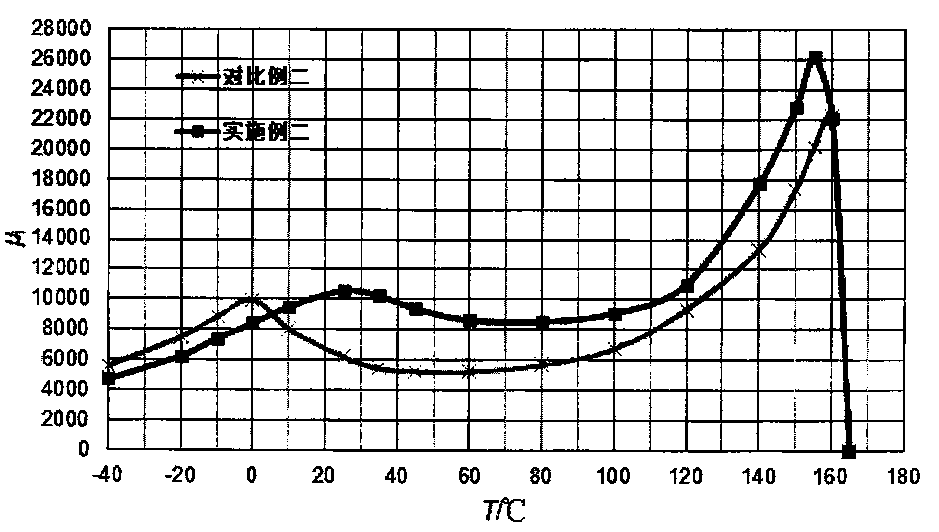

Embodiment 2

[0080] The preparation method of the second kind of high magnetic permeability MnZn ferrite material for automotive electronics, the specific steps are as follows:

[0081] 1) Ingredients: the main component is 52.7mol% Fe 2 o 3 , 19.3mol% ZnO, and the rest is MnO; calculate the quality of the required raw materials according to the total set mass, the corresponding molar ratio and the purity of each raw material, and MnO will be converted into Mn 3 o 4 The quality of each raw material is weighed, and then 0.06wt% CuO auxiliary material is weighed according to the total set mass;

[0082] 2) Mixing: Use a vibration mill to mix the raw and auxiliary materials in step 1) for 30 minutes;

[0083] 3) Pre-sintering: Pre-sinter the raw materials mixed in step 2) at 900°C for 2 hours in a box furnace or a rotary kiln;

[0084] 4) Pulverization: Add 0.06wt% CaCO to the calcined material produced in step 3) 3 , 0.02wt%Ta 2 o 5 , 0.02wt%In 2 o 3 , 0.02wt%Bi 2 o 3 After the au...

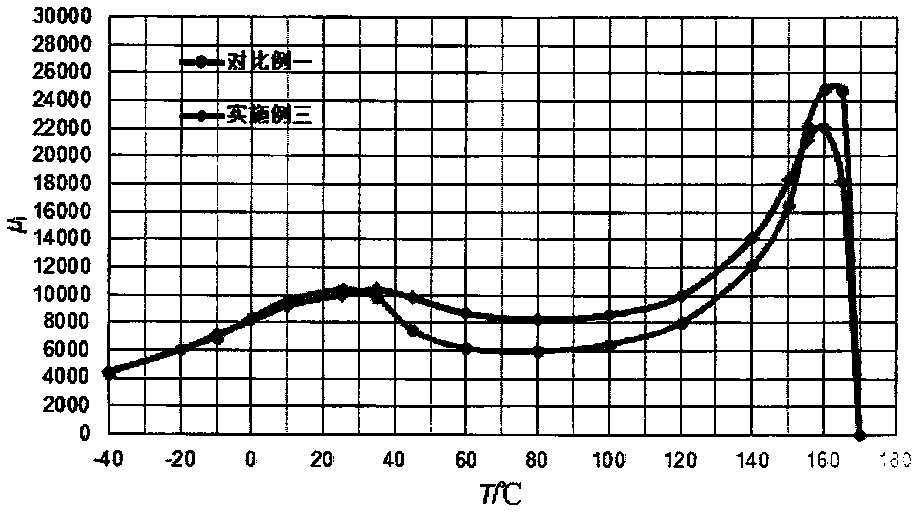

Embodiment 3

[0115] The preparation method of the third kind of high magnetic permeability MnZn ferrite material for automotive electronics, the specific steps are as follows:

[0116] 1) Ingredients: the main component is 52.66mol% Fe 2 o 3 , 18.3mol% of ZnO, and the rest is MnO; calculate the quality of the required raw materials according to the total set mass, the corresponding molar ratio and the purity of each raw material, and MnO will be converted into Mn 3 o 4 The quality of each raw material is weighed, and then 0.04wt% CuO auxiliary material is weighed according to the total set mass;

[0117] 2) Mixing: Use a vibration mill to mix the raw and auxiliary materials in step 1) for 30 minutes;

[0118] 3) Pre-sintering: Pre-sinter the raw materials mixed in step 2) in a box furnace or a rotary kiln at 950°C for 2 hours;

[0119] 4) Pulverization: add 0.07wt% CaCO to the calcined material produced in step 3) 3 , 0.02wt%Ta 2 o 5 , 0.01wt%In 2 o 3 , 0.02wt%Bi 2 o 3 After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com