A kind of activation method of wood fiber

A technology of wood fiber and activation method, which is applied in the field of activation and can solve the problem of low reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

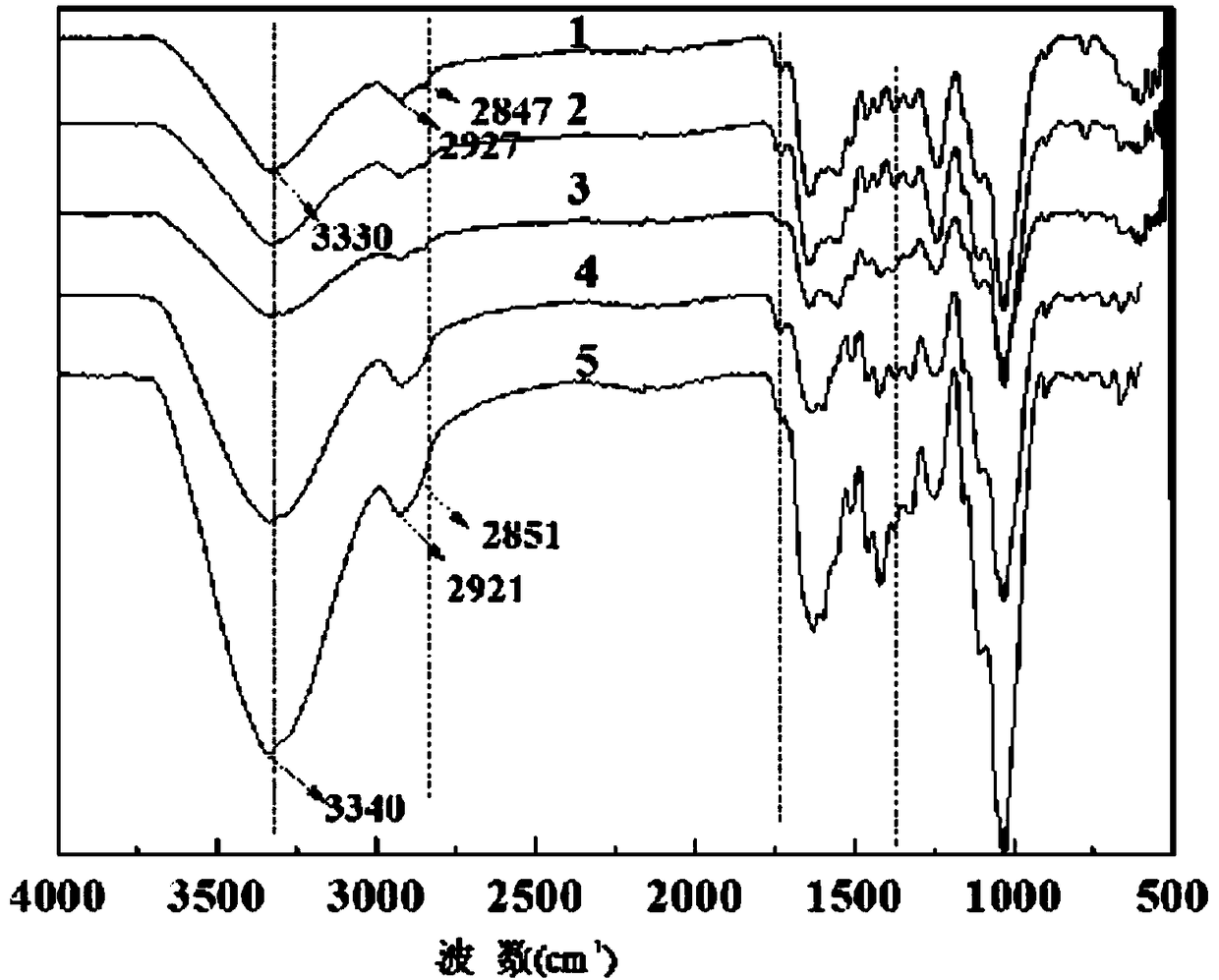

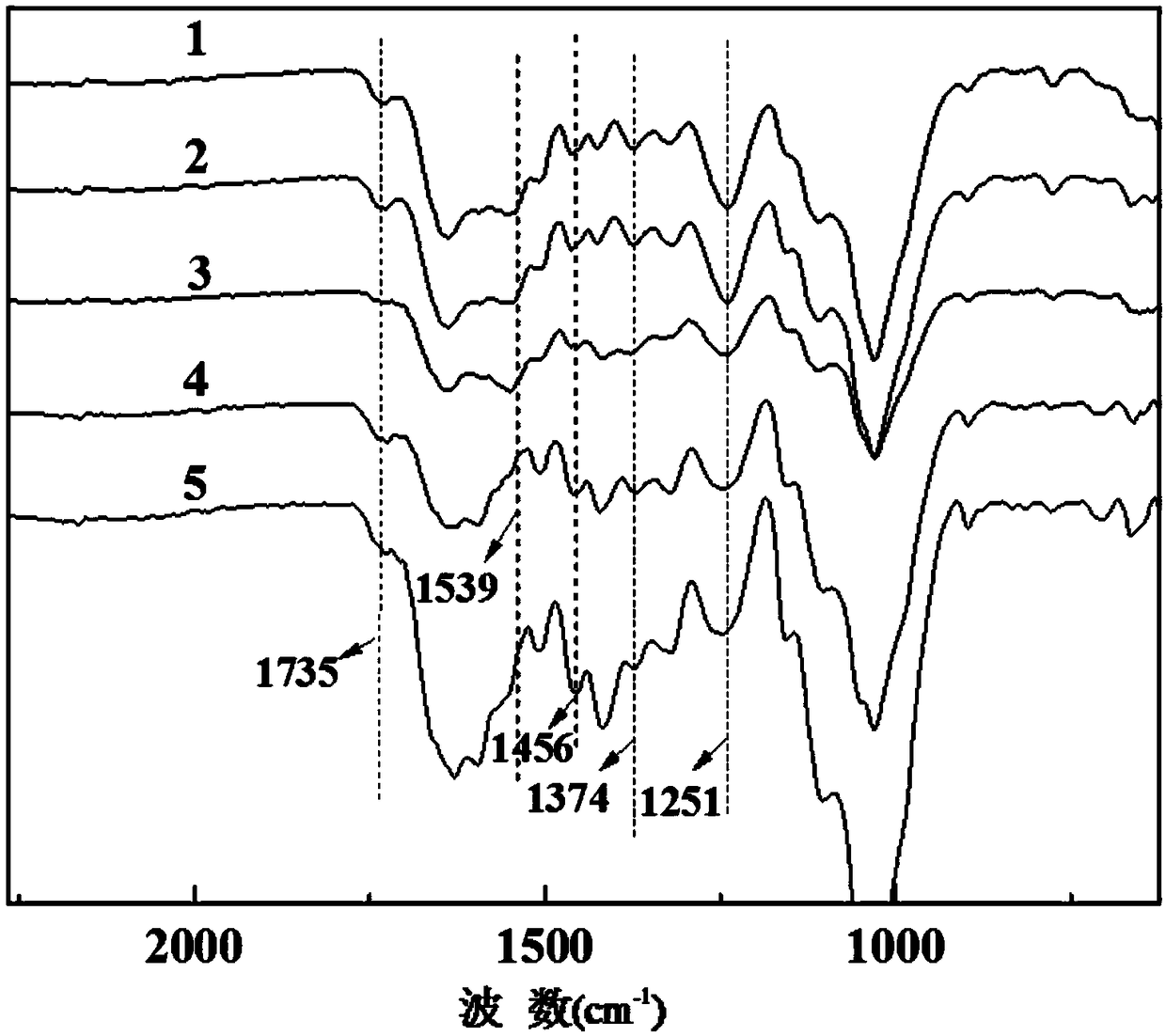

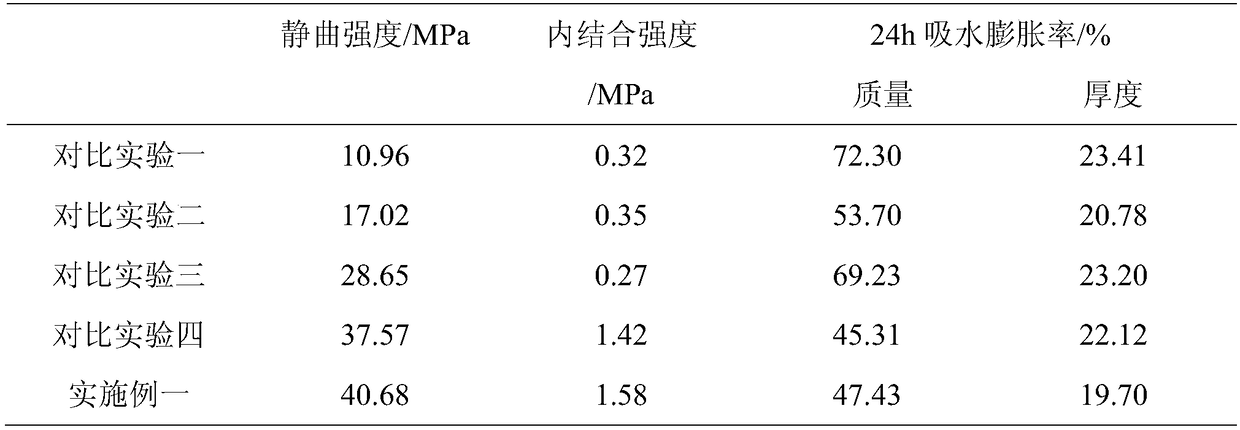

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the activation method of a kind of wood fiber of the present embodiment is to carry out according to the following steps:

[0022] 1. Prepare the mixed aqueous solution of alkali-polyethylene glycol-amino compound:

[0023] adding the base, polyethylene glycol and amino compound into water, stirring and dissolving to obtain a mixed aqueous solution of base-polyethylene glycol-amino compound;

[0024] The mass percent of alkali in the mixed aqueous solution of alkali-polyethylene glycol-amino compound is 5% to 10%; the mass percent of polyethylene glycol in the mixed aqueous solution of alkali-polyethylene glycol-amino compound 4% to 8%; the mass percentage of the amino compound in the alkali-polyethylene glycol-amino compound mixed aqueous solution is 4% to 8%;

[0025] The alkali is one or a mixture of sodium hydroxide and potassium hydroxide; the polyethylene glycol is polyethylene glycol 200, polyethylene glycol 300, polyethylene glycol 400 ...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass percentage of alkali in the mixed aqueous solution of alkali-polyethylene glycol-amino compound described in step 1 is 6%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass percent of polyethylene glycol in the mixed aqueous solution of alkali-polyethylene glycol-amino compound described in step one is 6% . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com