Method for co-production of furfural and glue-free fiberboards by using reeds

A technology of fiberboard and furfural, which is applied in the field of furfural co-production of non-adhesive fiberboard from reeds, can solve the problems of underutilization of hemicellulose, uneven distribution of laccase enzyme activity, and long microbial growth cycle, so as to facilitate equipment selection, The effect of increasing the content of active groups and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

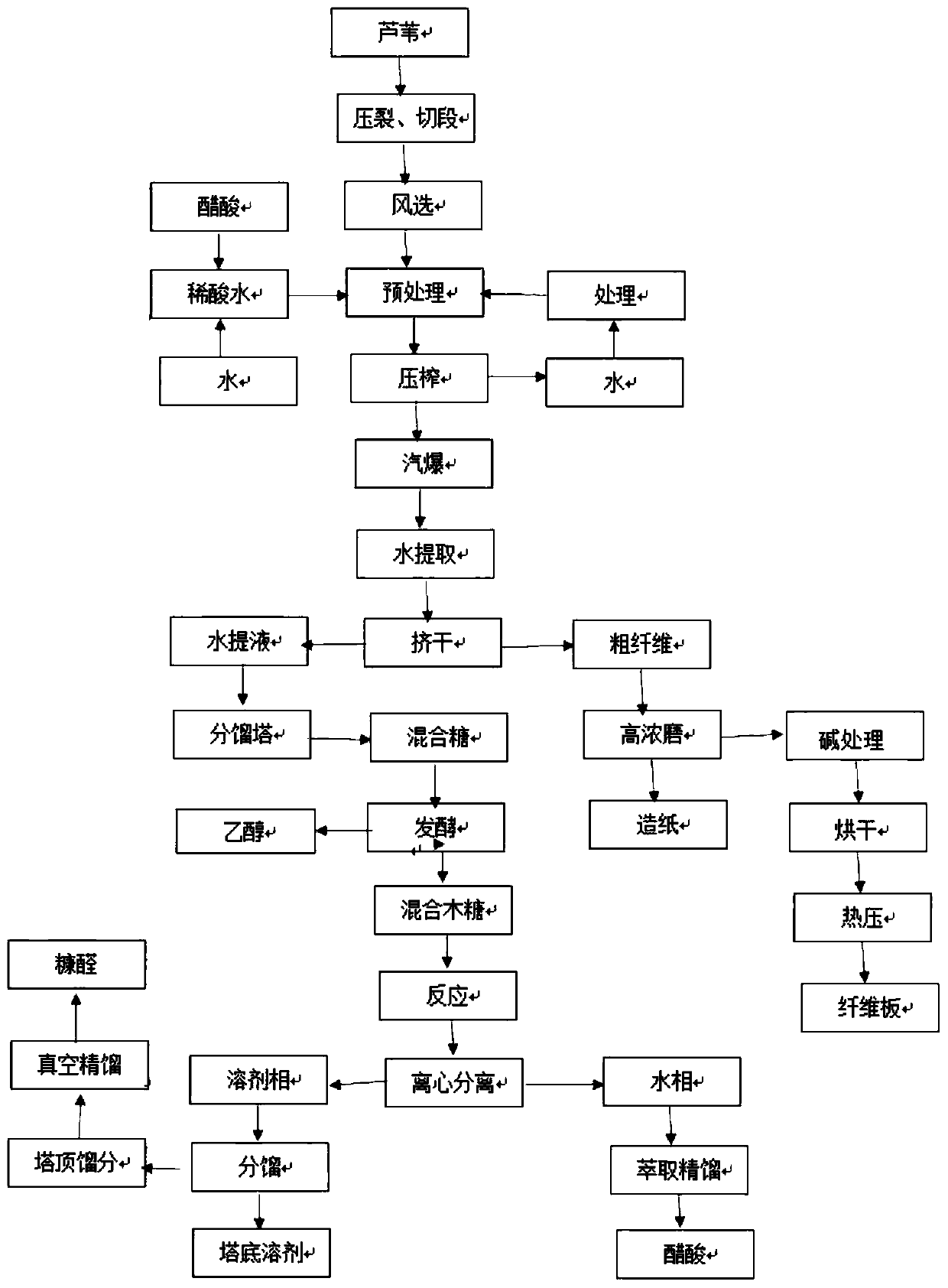

[0058] A method for preparing furfural co-production glue-free fiberboard from reeds, comprising the following steps:

[0059] (1) The raw material reed is fractured and cut into sections to make the length 20-40mm;

[0060] (2) by wind conveying, the reed leaves, reed flowers and flute membrane impurities in the reeds are separated, and the remaining reeds are raw materials for steam explosion;

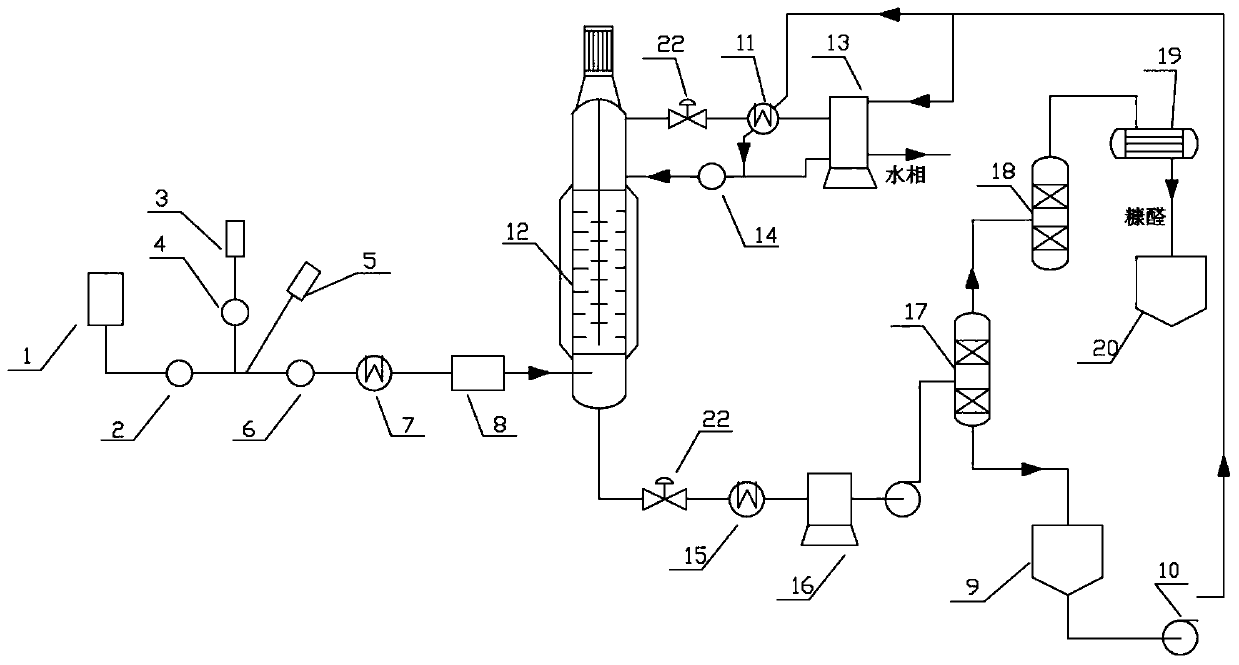

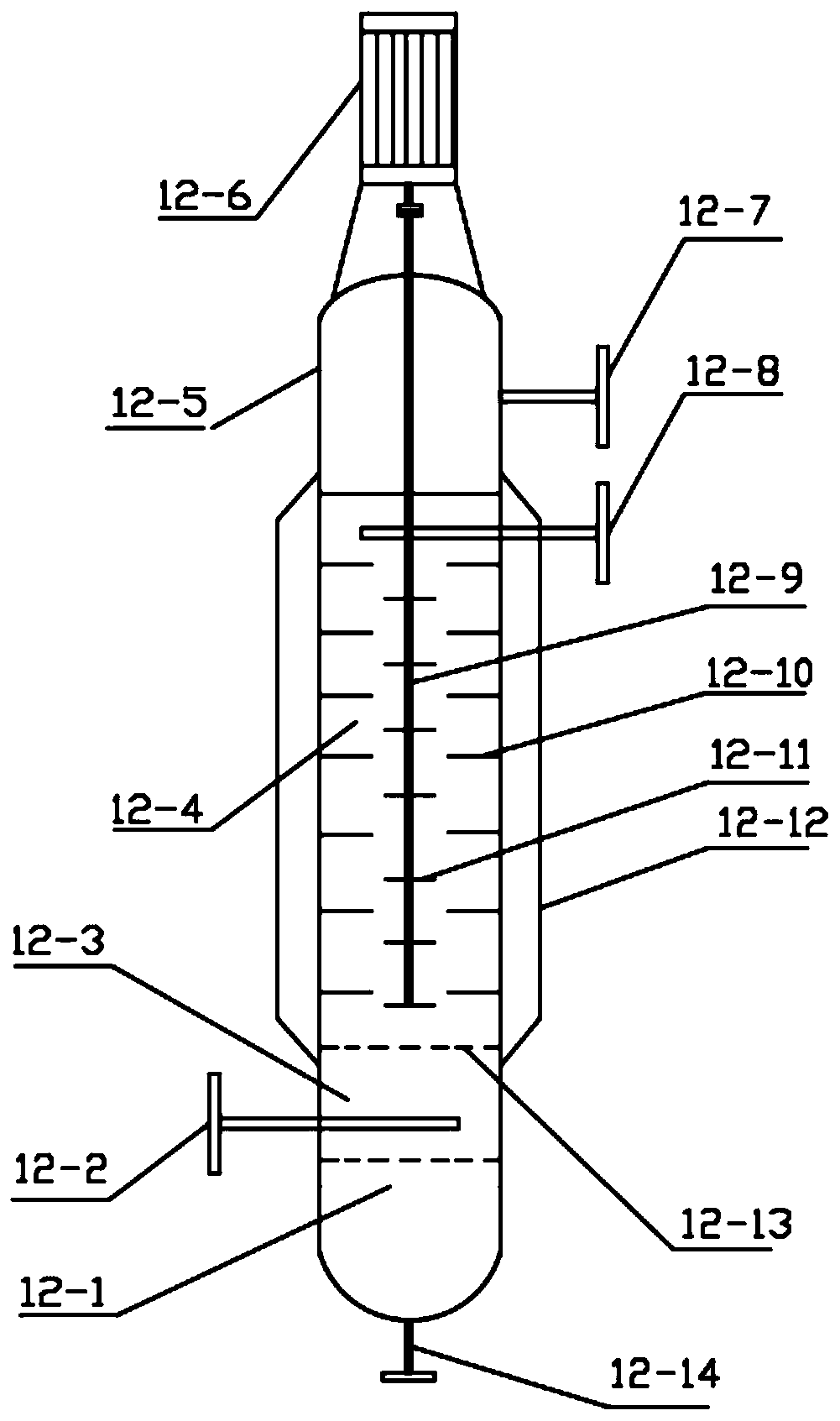

[0061] (3) adding mass concentration to the reed steam explosion raw material obtained in step (2) is 1% dilute acetic acid, mix homogeneously with a mixer and maintain 30 minutes, the solid-to-liquid ratio in the mixer is 1:6; the mixer is Ribbon mixer or tumble mixer. Then the reed after the mixed acid is sent into the steam blaster for instant blasting. The conditions for instant blasting in the steam blaster are: steam pressure 1.4Mpa, temperature 180-200°C, holding time 8 minutes; the material after steam explosion is made into 24wt % thick pulp, grind into fluffy fibrous form...

Embodiment 2

[0071] A method for extracting xylose by reed steam explosion to prepare furfural, comprising the following steps:

[0072] (1) The raw material reed is fractured and cut into sections to make the length 20-40mm;

[0073] (2) by wind conveying, the reed leaves, reed flowers and flute membrane impurities in the reeds are separated, and the remaining reeds are raw materials for steam explosion;

[0074] (3) adding concentration to the reed steam explosion raw material obtained in step (2) is 1% dilute acetic acid, mix uniformly with a mixer and maintain 30 minutes, the solid-liquid ratio in the mixer is 1:6; Ribbon mixer or tumble mixer. Then the reed after the mixed acid is sent into the steam blaster for instant blasting in the steam blaster. The conditions for instant blasting in the steam blaster are: steam pressure 1.4Mpa, temperature is 180-200°C, and the maintenance time is 8 minutes; % thick pulp, grind into fluffy fibrous form with high consistency mill, and then wash...

Embodiment 3

[0082] The operating conditions are the same as in Example 1, except that the concentration of the xylose solution is changed to 24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com