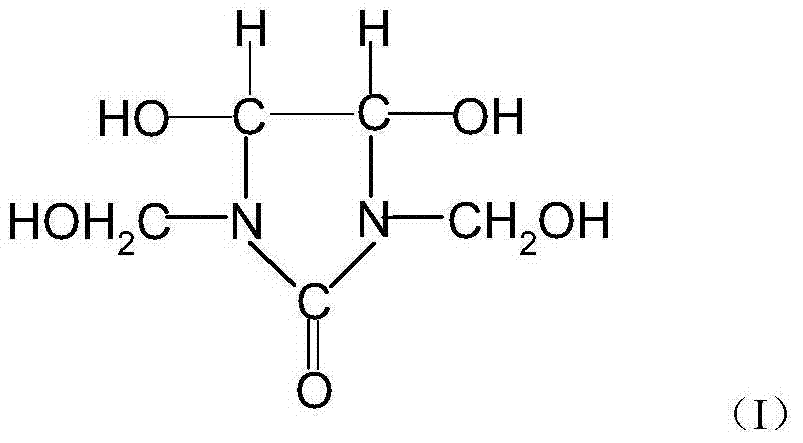

Improved preparation method of dimethylol dihydroxy ethylene urea

A technology of dimethylol dihydroxyethylene urea and formaldehyde, which is applied in the fields of fiber treatment, textiles and papermaking, organic chemistry, etc., and can solve the problem of etherification modification reaction, poor storage stability, and glyoxal conversion rate that affect the product , High-concentration product stability and reactivity are rarely involved in issues such as high conversion rate, stable reaction and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

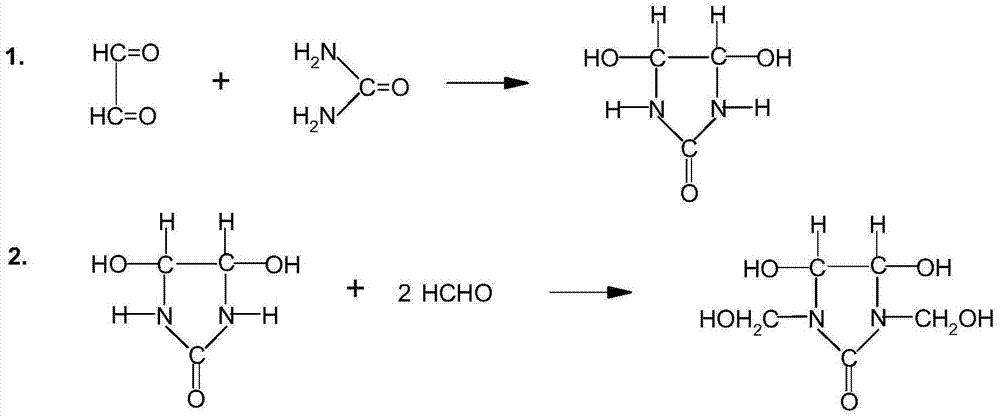

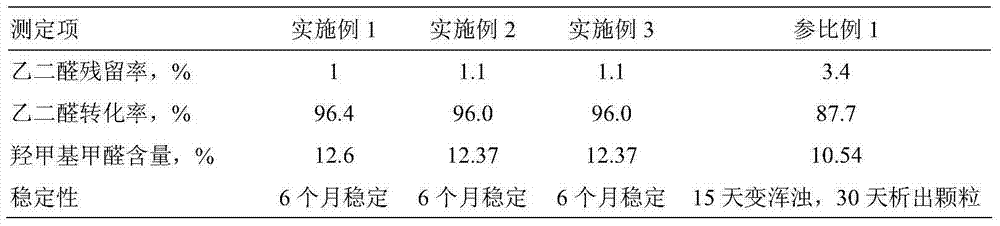

[0052] In a 1-liter four-necked round-bottomed flask equipped with a stirrer, a thermometer and a condenser, add 290 g of glyoxal (content 40%), then add 126 g of urea (content 99%), and stir to dissolve at 35°C. Then add 0.12 g of methanesulfonic acid (content 70%) and 0.60 g of sodium methanesulfonate (content 98%), and react at 40 °C for 2 hours; then add 0.20 g of sodium methanesulfonate, heat up to 55 °C, The reaction was continued for 2 hours. The residual amount of glyoxal was determined (see Table 1 for the results).

[0053] Then the reactant was cooled to 50°C, 2.6 g of disodium hydrogen phosphate and 0.16 g of sodium dihydrogen phosphate were added, and a mixture of 300 g of formaldehyde solution (37%) and 2.5 g of dimethylaminoethanol (dimethylaminoethanol) was added dropwise for 1-2 hours. Aminoethanol was added to the formaldehyde solution in advance), and the reaction was continued at 50 ° C for 4 hours to obtain a light yellow transparent liquid. Determinatio...

Embodiment 2

[0056] In a 1L four-necked round-bottomed flask equipped with a stirrer, a thermometer and a condenser, add 290 g of glyoxal (content 40%), then add 130 g of urea (content 99%), and stir to dissolve at 35°C. Then add 0.21 g of ethyl sulfonic acid (content 70%), 0.82 g of sodium ethyl sulfonate (content 98%), and react at 40°C for 2 hours; The reaction was continued for 2 hours. The residual amount of glyoxal was determined (see Table 1 for the results).

[0057] Then add 2.8 g of disodium hydrogen phosphate, 0.20 g of sodium dihydrogen phosphate, and dropwise add a mixture of 300 g of formaldehyde solution (37%) and 2.5 g of dimethylaminoethanol and 1.5 g of diethylaminopropanol for 1-2 hours (dimethylaminoethanol). Aminoethanol and diethylaminopropanol were added to the formaldehyde solution in advance), and the reaction was continued at 55°C for 3 hours to obtain a light yellow transparent liquid. Determination of active group methylol formaldehyde content (the results are...

Embodiment 3

[0060] In a four-necked round-bottomed flask equipped with a stirrer, a thermometer and a condenser, add 290 g of glyoxal (content 40%), then add 130 g of urea (content 99%), and stir to dissolve at 35°C. Then add 0.30 g of benzenesulfonic acid (content 80%), 0.80 g of sodium benzenesulfonate (content 98%), and react at 40°C for 2 hours; then add 0.45g of sodium benzenesulfonate, heat up to 50°C, and continue reaction 2 Hour. The residual amount of glyoxal was determined (see Table 1 for the results).

[0061] Then add 2.8g of dipotassium hydrogen phosphate, 0.20g of potassium dihydrogen phosphate, and dropwise add a mixture of 300g of formaldehyde solution (37%) and 2.5g of dimethylaminoethanol and 1.5g of diethylaminopropanol for 1-2 hours (dimethylaminoethanol). Aminoethanol and diethylaminopropanol were added to the formaldehyde solution in advance), and the reaction was continued at 55°C for 3 hours to obtain a light yellow transparent liquid. Determination of active gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com