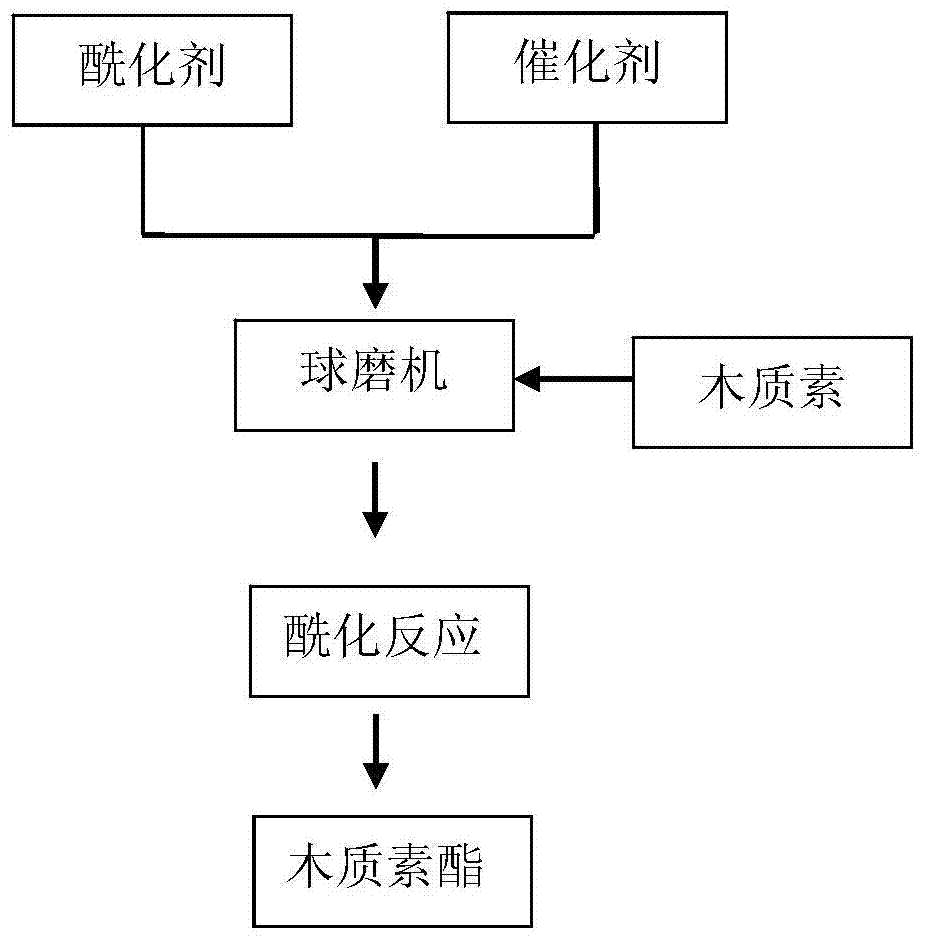

A kind of method for mechanically activating solid phase reaction to prepare lignin ester

A solid-phase reaction and mechanical activation technology is applied in the field of preparation of lignin esters, which can solve the problems of difficulty in solvent recovery, difficulty in direct modification and utilization, and high equipment cost, and achieves a time-saving and simple recovery process, and is easy to realize industrialized production. , Solve the effect of high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Lignin Acetate

[0031] Weigh the reaction material according to the ratio of organic lignin: acetic anhydride: 4,4-dimethylaminopyridine = 15g: 43.1g (0.42mol): 0.3g, and put the volume of the reaction material and the grinding medium according to the ratio of 100g: 150mL In the ball mill, the grinding balls are zirconia balls with a diameter of 6 mm. Stirring at a low speed of 150 r / min in a constant temperature water bath at 90 ° C for 2 h, stop heating and stirring, and cool rapidly to obtain crude lignin esters, and mix lignin The crude ester is separated from the grinding balls, the grinding balls and the crude lignin ester are cleaned with deionized water respectively; the crude lignin is left to stand for 15 minutes in deionized water to precipitate solids, and the solids are separated by filtration, and the filter cake is washed with deionized water Until the filtrate is neutral, lignin acetate is obtained.

[0032] The obtained lignin acetate w...

Embodiment 2

[0034] Preparation of Lignin Propionate

[0035]Weigh the reaction material according to the ratio of sodium lignosulfonate: propionic anhydride: 4,4-dimethylaminopyridine=15g:30g (0.23mol):0.3g, and stack the volume of the reaction material and the grinding medium according to the ratio of 100g:200mL Put it in a ball mill, the balls are zirconia balls with a diameter of 6mm, and carry out the acylation reaction at 100r / min at a low speed in a constant temperature water bath at 80°C for 3h, stop heating and stirring, and cool quickly to obtain crude lignin ester, and The crude vegan ester is separated from the grinding ball, and the grinding ball and the crude lignin ester are cleaned with deionized water; the solid is precipitated after standing in ether for 0.5 h, and the solid is separated by filtration, and the filter cake is washed 3 times with ether, each time 50 mL , to obtain lignin propionate.

[0036] The obtained lignin propionate was measured by an ultraviolet spe...

Embodiment 3

[0038] Preparation of lignin butyrate

[0039] Weigh the reaction material according to the ratio of unactivated alkali lignin: butyric anhydride: pyridine=15g:30g (0.19mol):0.5g, put the reaction material and the volume of the grinding medium in the ball mill according to the ratio of 100g:300mL, and grind the ball It is a zirconia ball with a diameter of 6mm. Stir at a low speed of 200r / min in a constant temperature water bath at 50°C for acylation reaction for 4 hours, stop heating and stirring, and cool quickly to obtain crude lignin ester, and separate the crude lignin ester from the balls , the grinding ball and the crude lignin ester were cleaned with an ethanol-water solution with a volume ratio of 1:1; the crude lignin ester was left to stand for 1 hour in an ethanol-water solution with a volume ratio of 1:1 to precipitate a solid, and the solid was separated by filtration. Wash the filter cake with deionized water until the filtrate is neutral to obtain lignin butyra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com