Surface sulfonated polyether ether ketone micro nanoparticle/ sulfonated polyether ether ketone composite membrane, and preparation method thereof

A technology of sulfonated polyether ether ketone and micro-nano particles, which is applied in the field of polymer materials and can solve the problems of loss of mechanical properties of membrane materials and poor dimensional stability of membrane materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

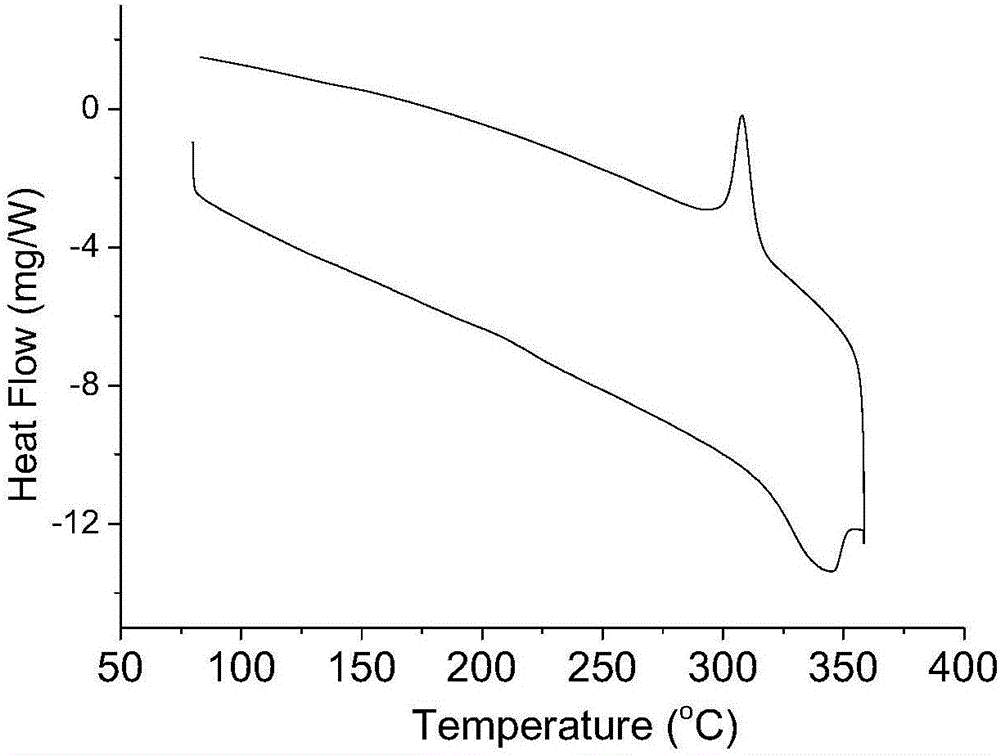

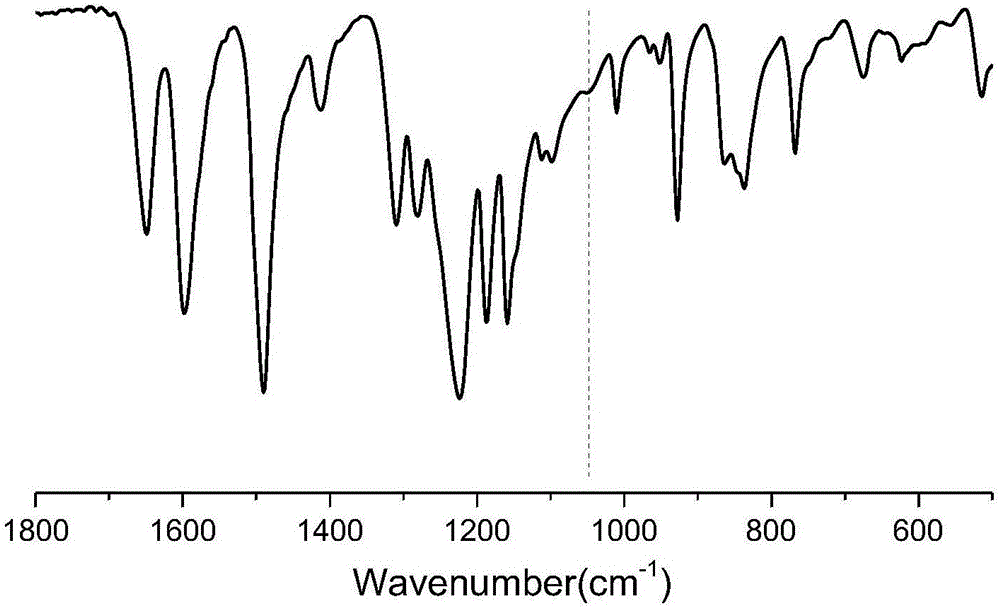

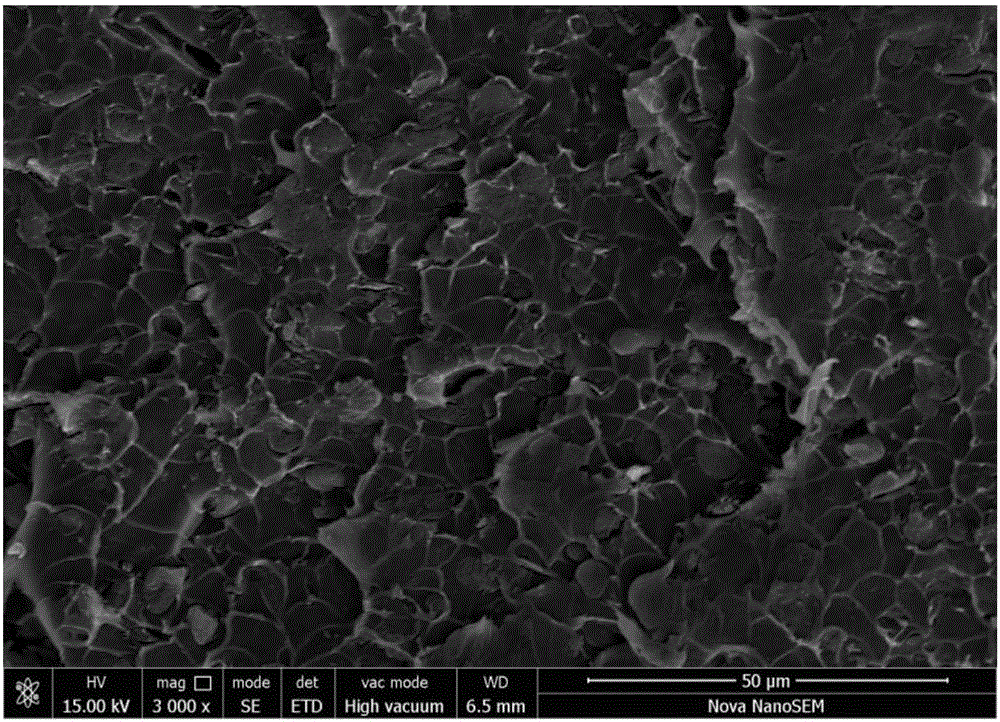

[0020] Preparation of surface sulfonated polyetheretherketone micro-nanoparticles on the scale of 1 micron: add 300mL of dichloromethane and 0.3g of chlorosulfonic acid into a 500mL three-necked bottle, stir well and add 10g of polyether ether with an average particle size of 1 micron Ketone particles (purchased from Jida Special Plastic Engineering Research Co., Ltd., melt index 10g / 10min), stirred at room temperature for 5 minutes, filtered and washed the obtained solids, repeated filtering and washing operations 4 times, stirring and washing for 1 hour each time, and finally filtered again Finally, the solid matter was dried at 120° C. to obtain surface sulfonated polyether ether ketone micro-nano particles with a yield of 99%. Although the particle surface is sulfonated, the polyether ether ketone particles still maintain the original crystalline structure. From figure 1 It can be seen from the DSC curve that the polymer particles still have the melting point and crystall...

Embodiment 2

[0022] Preparation of sulfonated polyetheretherketone micro-nanoparticles on the surface of 1 micron scale: add 300mL chloroform and 0.3g chlorosulfonic acid to a 500mL three-neck flask respectively, stir well and add 10g polyether ether ketone with an average particle size of 1 micron Particles (purchased from Jida Special Plastic Engineering Research Co., Ltd., melt index 10g / 10min), stirred at room temperature for 5 minutes, filtered and washed the obtained solids, repeated filtering and washing operations 4 times, stirring and washing for 1 hour each time, and finally filtered again Dry the solid at 120° C. to obtain surface sulfonated polyether ether ketone micro-nano particles with a yield of 99%.

Embodiment 3

[0024] By changing the particle size of the polyether ether ketone particles in Example 1, from 1 nanometer scale to 20 micron scale, surface sulfonated polyetheretherketone micro-nano particles can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com