A surface sulfonated polyetheretherketone micro-nano particle/sulfonated polyetheretherketone composite film and its preparation method

A technology of sulfonated polyether ether ketone and micro-nano particles, applied in the field of polymer materials, can solve the problems of loss of mechanical properties of membrane materials, deterioration of dimensional stability of membrane materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

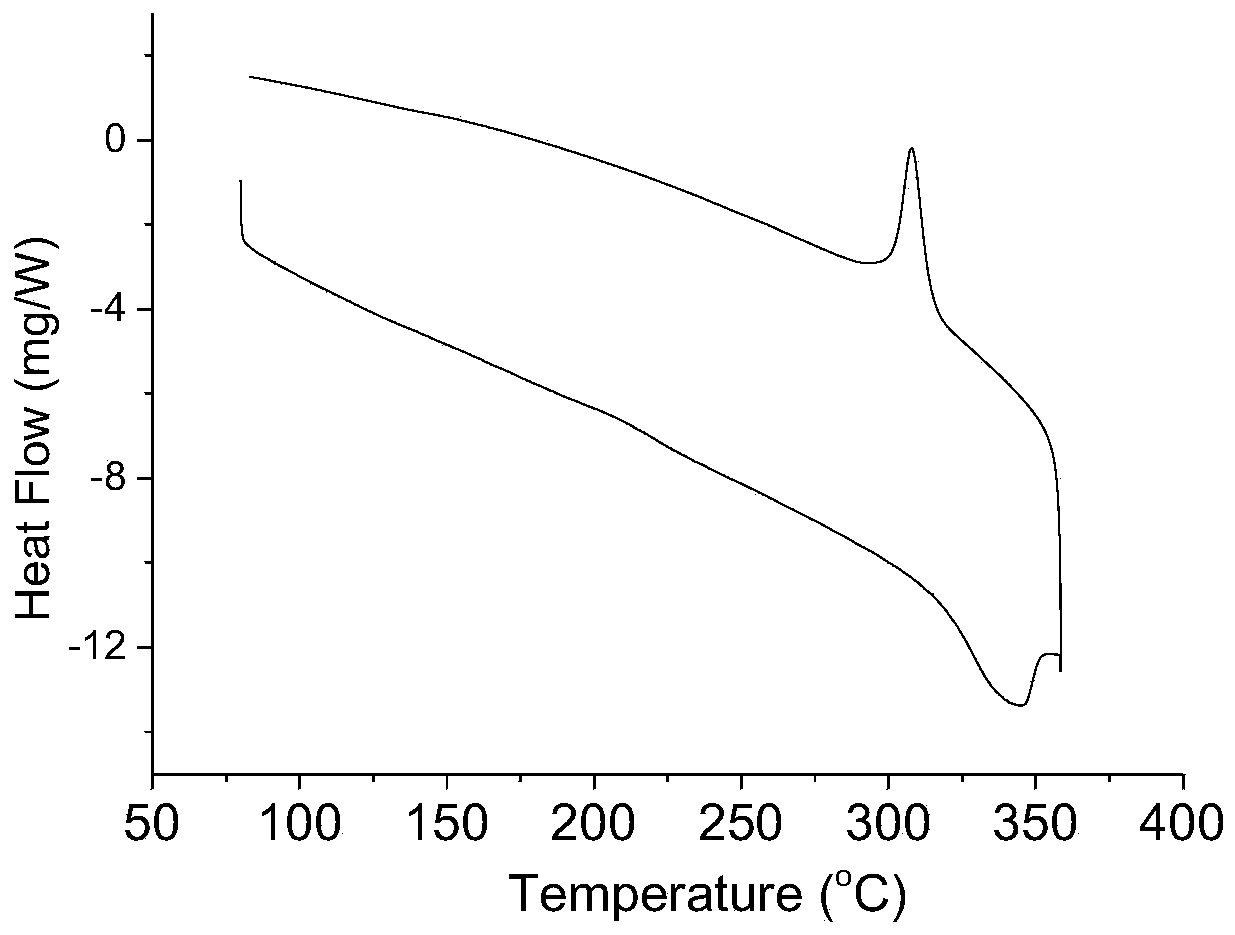

[0020] Preparation of surface sulfonated polyetheretherketone micro-nanoparticles on the scale of 1 micron: add 300mL of dichloromethane and 0.3g of chlorosulfonic acid into a 500mL three-necked bottle, stir well and add 10g of polyether ether with an average particle size of 1 micron Ketone particles (purchased from Jida Special Plastic Engineering Research Co., Ltd., melt index 10g / 10min), stirred at room temperature for 5 minutes, filtered and washed the obtained solids, repeated filtering and washing operations 4 times, stirring and washing for 1 hour each time, and finally filtered again Finally, the solid matter was dried at 120° C. to obtain surface sulfonated polyether ether ketone micro-nano particles with a yield of 99%. Although the particle surface is sulfonated, the polyether ether ketone particles still maintain the original crystalline structure. From figure 1 It can be seen from the DSC curve that the polymer particles still have the melting point and crystall...

Embodiment 2

[0022] Preparation of sulfonated polyetheretherketone micro-nanoparticles on the surface of 1 micron scale: add 300mL chloroform and 0.3g chlorosulfonic acid to a 500mL three-neck flask respectively, stir well and add 10g polyether ether ketone with an average particle size of 1 micron Particles (purchased from Jida Special Plastic Engineering Research Co., Ltd., melt index 10g / 10min), stirred at room temperature for 5 minutes, filtered and washed the obtained solids, repeated filtering and washing operations 4 times, stirring and washing for 1 hour each time, and finally filtered again Dry the solid at 120° C. to obtain surface sulfonated polyether ether ketone micro-nano particles with a yield of 99%.

Embodiment 3

[0024] By changing the particle size of the polyether ether ketone particles in Example 1, from 1 nanometer scale to 20 micron scale, surface sulfonated polyetheretherketone micro-nano particles can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com