A kind of high-temperature solid state reaction method prepares the method for fesb2

A high-temperature solid-state reaction and raw material technology, applied in the field of thermoelectric materials, can solve problems such as complex preparation process, long annealing cycle, and accelerated reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

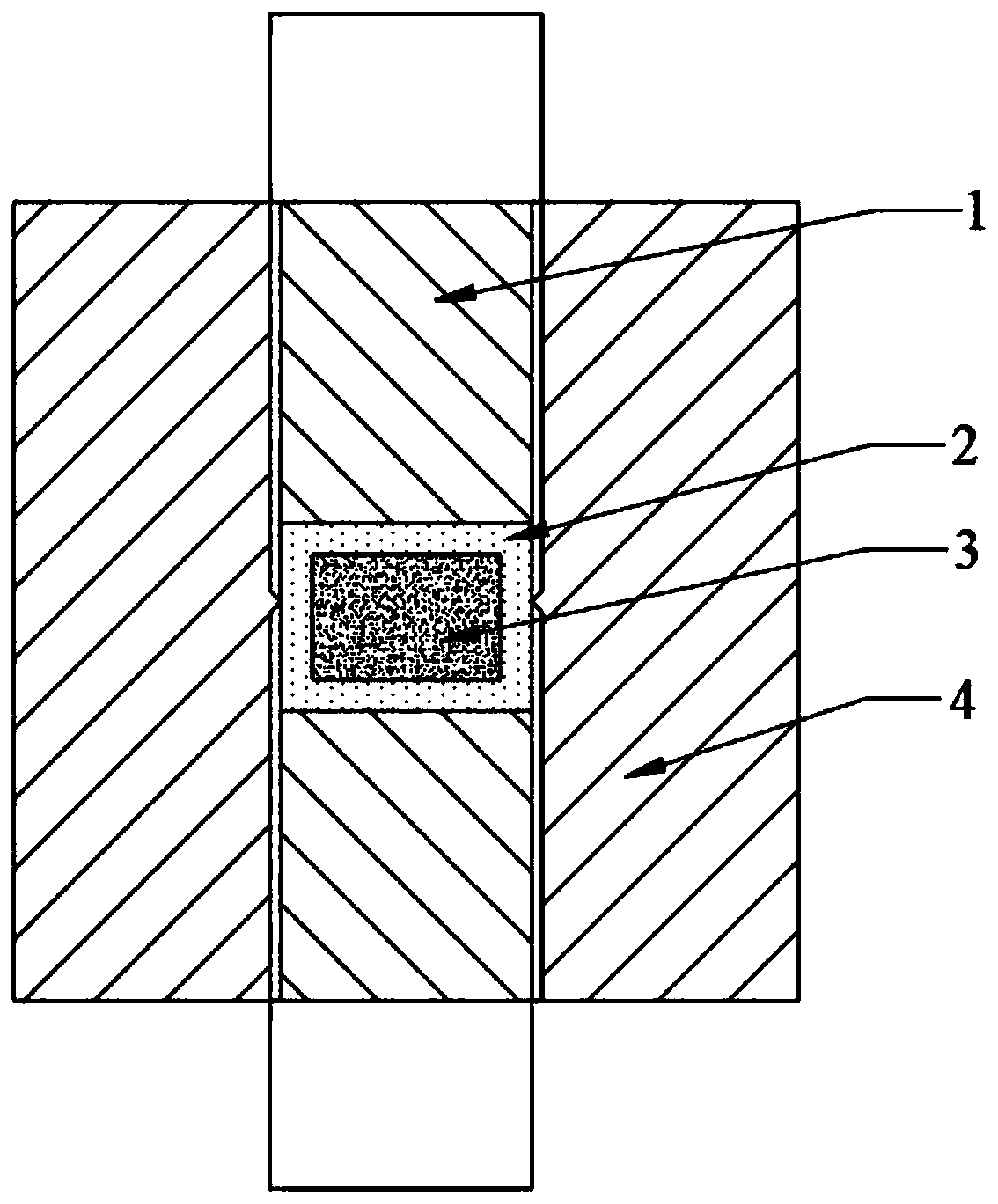

[0020] refer to figure 1 , the sintering mold adopted in the present invention is made up of plug 1, insulating material 2 and cylinder body 4, and the FeSb of powder pressing molding 2 Sample 3 is set therein. Plug 1 is made of pure copper or high manganese steel; isolation material 2 is made of boron nitride or zirconia; cylinder 4 is made of heat-resistant steel or stainless steel, FeSb 2 Sample 3 is a cylinder with a diameter of about a mm and a height of about h mm. The diameter of the plug 1 and the diameter of the sample inner hole of the cylinder 4 are standard threaded holes of about (a+5) mm, and the outer diameter of the cylinder 4 is 1 to 6 times the sample diameter a.

[0021] The initial raw material of the present invention adopts iron powder and antimony powder that purity is 99.99%, according to FeSb 2 After accurately weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com