Multibasic oxide filled and PEEK (polyether-ether-ketone)-based self-lubricating nanocomposite and preparation method thereof

A nanocomposite material and polyetheretherketone technology are applied in the field of multi-oxide filled polyetheretherketone-based self-lubricating nanocomposite materials and their preparation, and can solve problems such as the influence of tribological properties of polymer composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

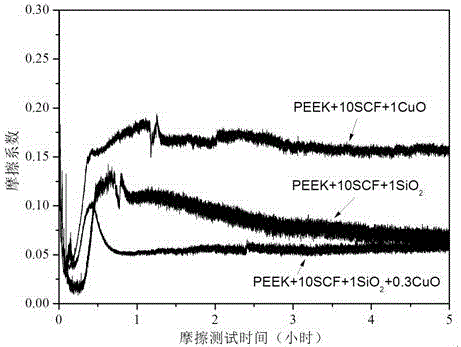

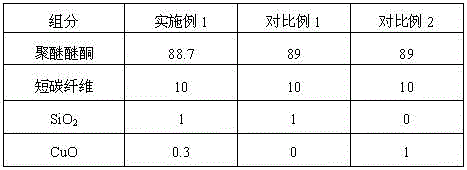

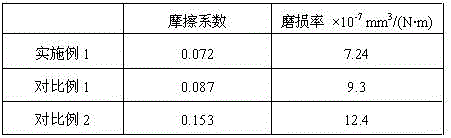

[0021] The volume percentage of the components of a polyether ether ketone-based self-lubricating nanocomposite filled with multiple oxides is: nano-CuO particles: 0.3%, nano-SiO 2 Granules: 1%, PEEK powder: 88.7%, short carbon fibers: 10%. First, nano-CuO and nano-SiO 2 The granules are mechanically mixed, then PEEK powder and short carbon fibers are added for further mixing. The mechanically mixed uniform powder is placed in a twin-screw extruder to melt and knead and extrude. The melt-extruded pellets are injected into an injection molding machine. The short carbon fiber is dried and used after ultrasonic cleaning, and the cleaning solvent is absolute ethanol. The heating temperature of the first zone of the twin-screw extruder is 370~375°C, the heating temperature of the second zone is 380~385°C, the heating temperature of the third zone is 390~395°C, the heating temperature of the fourth zone is 400~405°C, and the screw speed is 400rpm; The mold temperature is 180°C, ...

Embodiment 2

[0023] A multi-component oxide filled polyetheretherketone-based self-lubricating nanocomposite has a volume percentage of components: nano-CuO particles: 3%, nano-TiO 2 Granules: 7%, PEEK pellets: 75%, short glass fibers: 15%. First, nano-CuO and nano-TiO 2 The granules were mechanically mixed, and then PEEK pellets and short glass fibers were added for further mixing. Put the mechanically mixed homogeneous material in a twin-screw extruder to melt, knead and extrude it. The melt-extruded pellets are injected into an injection molding machine. The short glass fiber is dried and used after ultrasonic cleaning, and the cleaning solvent is acetone. The heating temperature of the first zone of the twin-screw extruder is 370~375°C, the heating temperature of the second zone is 380~385°C, the heating temperature of the third zone is 390~395°C, the heating temperature of the fourth zone is 400~405°C, and the screw speed is 200rpm; The mold temperature is 190°C, the injection bar...

Embodiment 3

[0025] The volume percentage of the components of a polyether ether ketone-based self-lubricating nanocomposite filled with multiple oxides is: nano Bi 2 o 3 Particles: 4%, Nano SiO 2 Granules: 9%, PEEK powder: 67%, short carbon fibers: 20%. First, the Nano Bi 2 o 3 and nano-SiO 2 The granules are mechanically mixed, then PEEK powder and short carbon fibers are added for further mixing. The mechanically mixed uniform powder is placed in a twin-screw extruder to melt and knead and extrude. The melt-extruded pellets are injected into an injection molding machine. The short carbon fiber is dried and used after ultrasonic cleaning, and the cleaning solvent is acetone. The heating temperature of the first zone of the twin-screw extruder is 370~375°C, the heating temperature of the second zone is 380~385°C, the heating temperature of the third zone is 390~395°C, the heating temperature of the fourth zone is 400~405°C, and the screw speed is 300rpm; The mold temperature is 20...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap