A kind of fluorescent ink and preparation method thereof

A fluorescent ink and fluorescent powder technology, which is applied in inks, household utensils, applications, etc., can solve the problems that affect the fluorescence intensity and light stability of fluorescent inks, the limited solubility of organic fluorescent materials, and the non-detection of benzene solvents, etc., to achieve benefits Industrialized mass production, energy-saving and environmentally friendly preparation methods, and good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

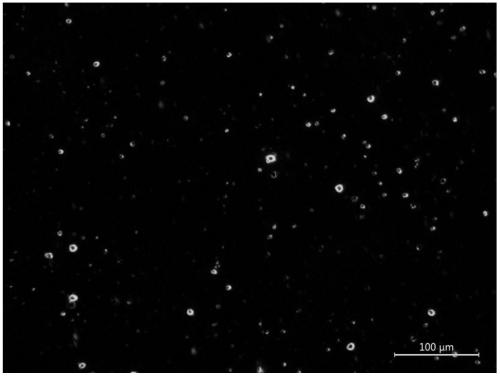

Image

Examples

Embodiment 1

[0026] A fluorescent ink, comprising the following components: fluorescent powder (2%), solvent II (37%) and polyamide resin (30%), n-butanol (30%), wax powder 0.5% and erucamide resin 0.5 %.

[0027] Among them, the preparation of fluorescent powder: the rare earth terbium salt (nitrate or chloride salt), alkali (sodium hydroxide or potassium hydroxide) and ligand 2,6-dihydroxybenzoic acid in a solvent (water or ethanol or water and ethanol) mixed solvent) to obtain a white powder, which glows bright green under ultraviolet light.

[0028] Preparation method: accurately weigh 2.4 grams of self-made fluorescent powder, 22.2 grams of isopropanol, 22.2 grams of methylcyclohexane, 36 grams of n-butanol, 36 grams of polyamide resin, 0.6 grams of wax powder and 0.6 grams of erucamide resin and Put 30 grams of glass beads in an iron can, seal the seal, put the iron can in a shaker to disperse for 30 minutes, and filter to obtain a fluorescent ink.

Embodiment 2

[0030] A fluorescent ink, comprising the following components: fluorescent powder (4%), solvent II (35%) and polyamide resin (30%), n-butanol (30%), wax powder 0.5% and erucamide resin 0.5 %.

[0031] Among them, the preparation of fluorescent powder: the rare earth terbium salt (nitrate or chloride salt), alkali (sodium hydroxide or potassium hydroxide) and ligand 2,6-dihydroxybenzoic acid in a solvent (water or ethanol or water and ethanol) mixed solvent) to obtain a white powder, which glows bright green under ultraviolet light.

[0032] Preparation method is identical with embodiment 1

Embodiment 3

[0034] A fluorescent ink, comprising the following components: fluorescent powder (3%), solvent II (36%) and polyamide resin (28%), n-butanol (32%), wax powder 0.5% and erucamide resin 0.5 %.

[0035] Among them, the preparation of fluorescent powder: the rare earth terbium salt (nitrate or chloride salt), alkali (sodium hydroxide or potassium hydroxide) and ligand 2,6-dihydroxybenzoic acid in a solvent (water or ethanol or water and ethanol) mixed solvent) to obtain a white powder, which glows bright green under ultraviolet light.

[0036] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com