Coke oven top plate pipe laid assembled type fixing rack and assembling method thereof

A fixing frame and pipe assembly technology, which is applied in coking ovens, coking oven heating, coking oven parts, etc., can solve the problems of material turnover and waste, large-diameter pre-embedded pipes cannot be directly fixed, etc., and achieve convenient adjustment in the installation process , easy dismantling, and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

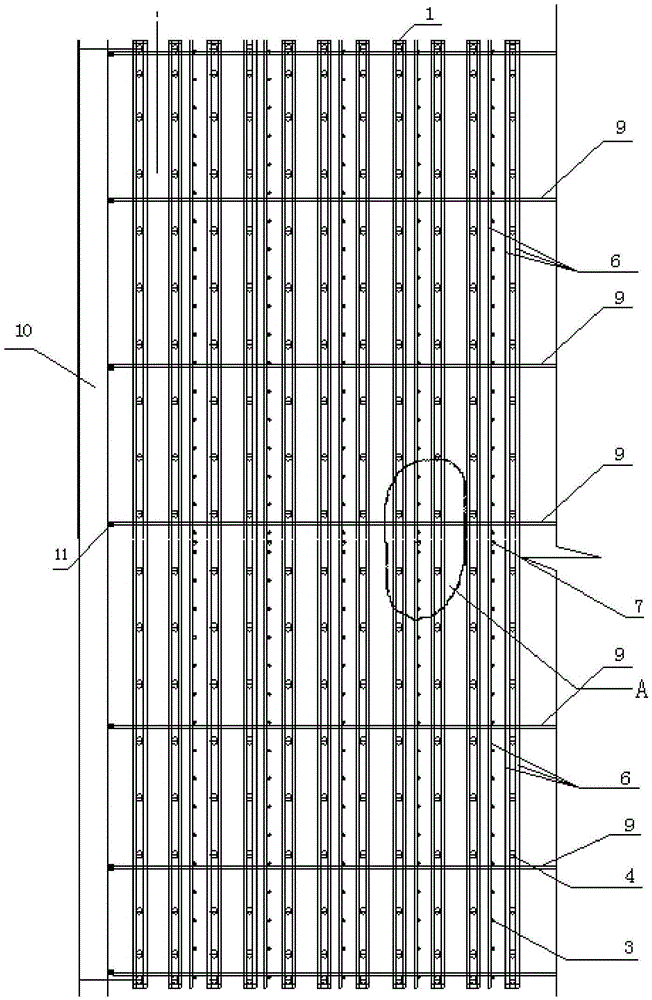

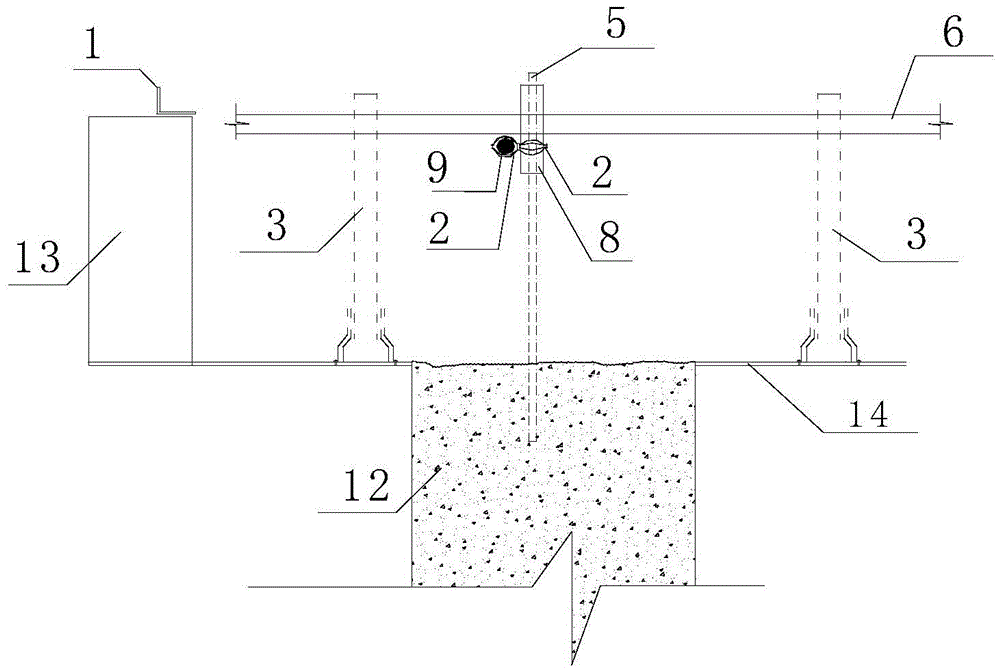

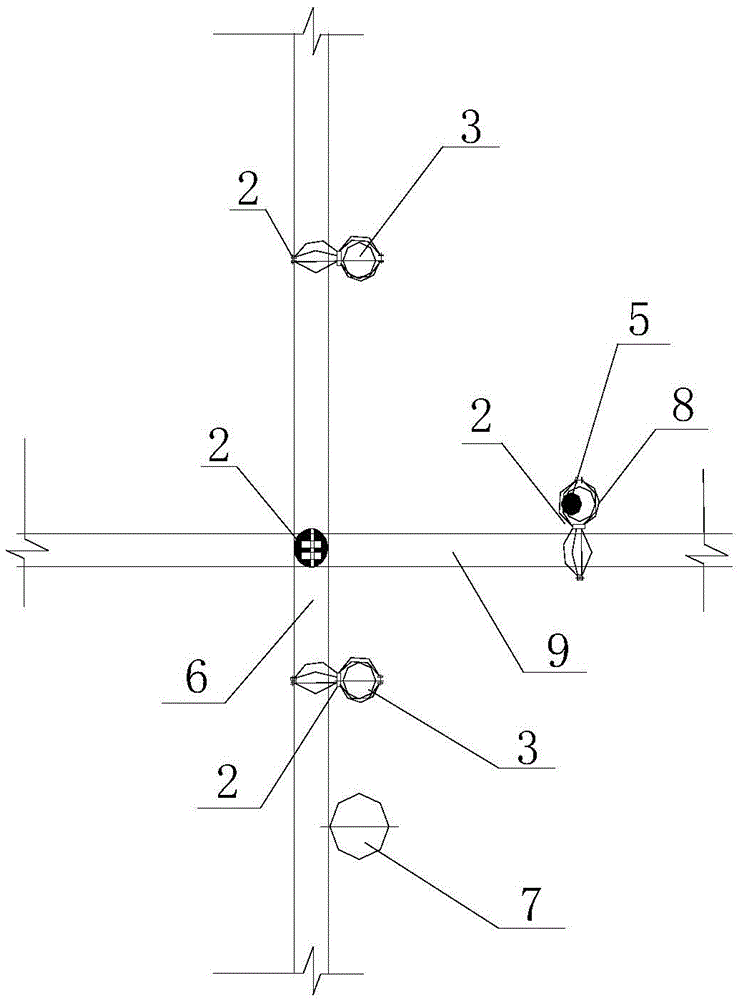

[0030] first part:

[0031] This construction method mainly uses the pre-embedded steel bars 5 at the column head during the construction of the coke oven short column to control the horizontal elevation of the horizontal and vertical scaffolding tubes. Use the side beam to install the angle steel scale 1 to control the center distance in the longitudinal direction of the buried pipe. The vertical and horizontal horizontal pipes arranged are used to make the overall scaffolding pipe grid, so as to control the buried pipes from shifting. Utilize the vertical surface of the concrete resistance wall at both ends to control the longitudinal horizontal pipe 9 from displacement.

[0032] the second part:

[0033] Specific implementation steps for fixing frame assembly:

[0034] Step 1: During the concrete construction of the short column of the coke oven foundation frame column, a short steel bar 5 is pre-embedded on each column head, and the height is higher than the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com