Automatic-batching straw biogas digester

A technology of automatic batching and biogas digesters, applied in the field of biogas, can solve the problems of low degree of automation and insufficient utilization rate, and achieve the effects of ensuring utilization rate, reducing heat transfer, and reducing heat emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

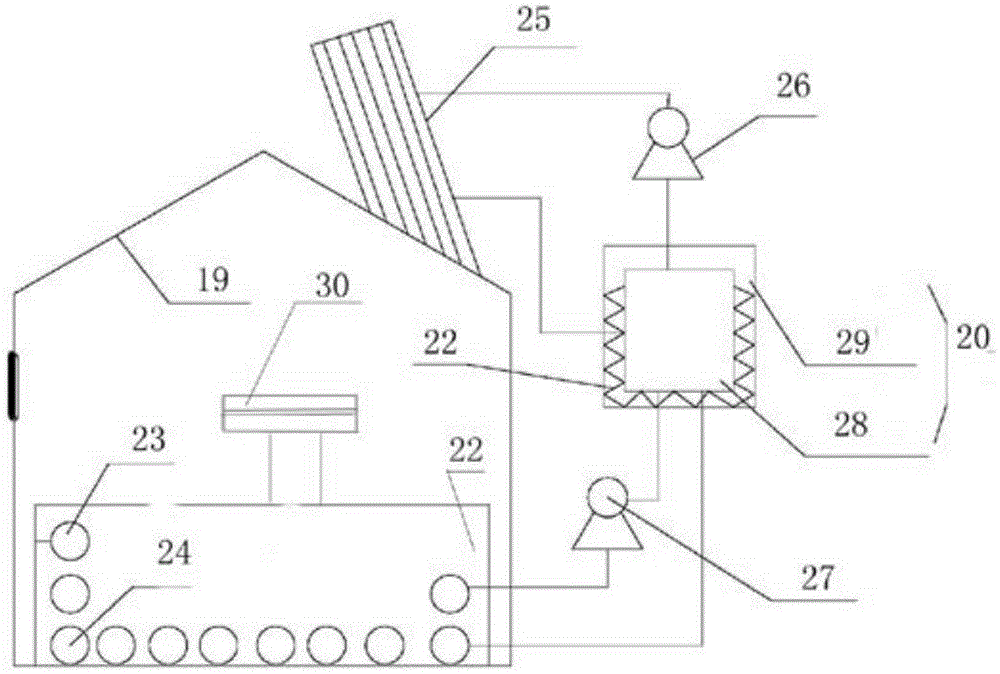

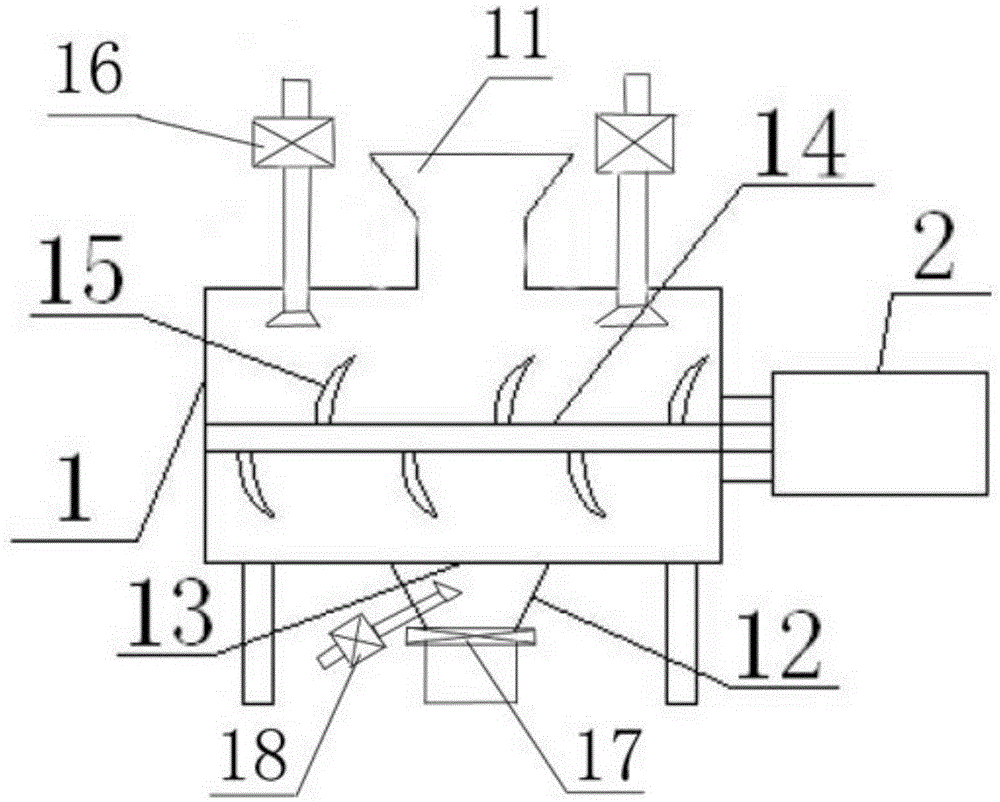

[0015] Such as Figure 1-2 A straw biogas digester with automatic batching shown includes a heat preservation chamber 19, a water collection tank 20, an electric heating pipe 21, an anaerobic pool 22, a solar heat collector 25 and a controller; it is characterized in that: the heat preservation chamber 19 is provided with A light-transmitting vertical window, the inner wall of which is provided with a heat storage layer for heat storage; the water collecting tank 20 is provided with a heat conduction plate, and the heat conduction plate divides the water collecting tank 20 into an inner box body 28 and an outer box body 29, and the inner box body An electric heating tube 21 is arranged between the body 28 and the outer box body 29, and the electric heating tube 21 communicates with the output end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com