A vacuum die-casting method for aluminum alloy cylinder without cylinder liner

A technology of vacuum die casting and aluminum alloy, applied in the field of engine aluminum cylinder block casting, can solve the problems of low yield, high cost of mass production, low efficiency, etc., to improve yield and production efficiency, reduce manufacturing costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

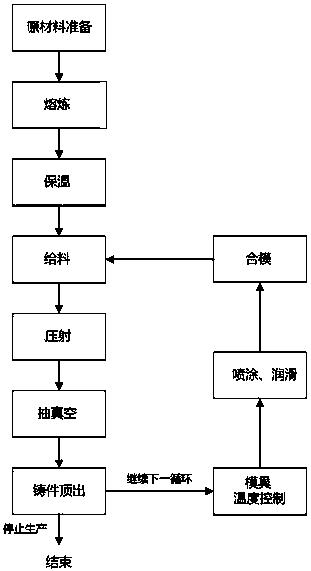

Image

Examples

Embodiment 1

[0032] Embodiment 1: A method for vacuum die-casting of an aluminum alloy cylinder block without cylinder liner, comprising the following steps:

[0033] 1) Melting: Melt the material ADC12 at 740±20°C, the proportion of new material is not less than 70%, then pour out the molten aluminum for refining and degassing, the temperature of the furnace is 740°C, the refining temperature is 700°C, the degassing time 5min,

[0034] 2) Heat preservation: put the molten aluminum prepared in step 1) in a heat preservation furnace at a heat preservation temperature of 660°C. If the aluminum liquid in the heat preservation furnace exceeds 4 hours, it needs to be deslagged. If the aluminum water exceeds 8 hours, it needs to be degassed and slag removed again. And carry out chemical composition analysis, qualified before use, aluminum water exceeds 48h, need to carry out ingot casting treatment;

[0035] 3) Mold pretreatment:

[0036] a. Preheat the mold in the cold mold state, and control...

Embodiment 2

[0043] Embodiment 2: A method for vacuum die-casting of an aluminum alloy cylinder block without cylinder liner, comprising the following steps:

[0044] 1) Melting: The material ADC12 is melted at 740±20°C, the proportion of new material is not less than 70%, and then the molten aluminum is poured out for refining and degassing. The furnace temperature is 720°C, the refining temperature is 740°C, and the degassing time is 10min,

[0045] 2) Heat preservation: Put the molten aluminum prepared in step 1) in a heat preservation furnace at a heat preservation temperature of 680°C. If the aluminum liquid in the heat preservation furnace exceeds 4 hours, deslagging treatment is required; if the aluminum liquid exceeds 8 hours, degassing and slag removal is required. And the chemical composition analysis is carried out, and it can be used only if it is qualified; if the aluminum water exceeds 48 hours, it needs to be cast into ingot;

[0046] 3) Mold pretreatment:

[0047] a. Preh...

Embodiment 3

[0054] Embodiment 3: A method for vacuum die-casting of an aluminum alloy cylinder block without cylinder liner, comprising the following steps:

[0055] 1) Melting: The material ADC12 is melted at 740±20°C, the proportion of new material is not less than 70%, and then the molten aluminum is poured out for refining and degassing. The furnace temperature is 760°C, the refining temperature is 720°C, and the degassing time is 7min,

[0056] 2) Heat preservation: Put the molten aluminum prepared in step 1) in a heat preservation furnace with a heat preservation temperature of 670°C. If the aluminum liquid in the heat preservation furnace exceeds 4 hours, it needs to be deslagged. If the aluminum water exceeds 8 hours, it needs to be degassed and slag removed again. And carry out chemical composition analysis, qualified before use, aluminum water exceeds 48h, need to carry out ingot casting treatment;

[0057] 3) Mold pretreatment:

[0058] a. Preheat the mold in the cold mold st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com