Aviation component cleaning agent and preparing method

A cleaning agent and component technology, which is applied in the cleaning agent and preparation of aviation parts, and in the field of aviation parts cleaning, can solve the problems of human body toxicity, aviation parts cleaning agent is flammable and explosive, and achieves non-toxicity to the human body, flash point High, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Cleaning agent composition: It is composed of n-alkane base solvent, ethylene glycol butyl ether active agent and N,N' - Composition of di-salicylidene propylenediamine active agent, the mixing ratio is 92%: 6.5%: 1.5%.

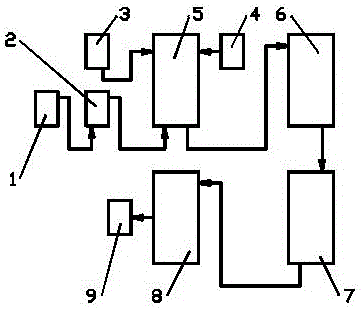

[0011] Cleaning agent preparation method: the nitrogen produced in the nitrogen machine 1 is filled into the nitrogen tank 2, and the nitrogen in the nitrogen tank is blown into the blending kettle 5; the n-paraffin basic solvent is pumped from the solvent tank 3 to the blending tank In the kettle, the ethylene glycol butyl ether active agent and passivator are N,N' - Disalicylidene propylenediamine is pumped from the additive tank 4 to the blending kettle; heated in a water bath to make the temperature in the reactor reach 50-55°C, and stirred at a constant speed for 3 hours; the mixed product is pumped to Cool to room temperature in the cooling tank 6; filter through the filter 7 under pressure; use the filling machine 8 to pack into the packaging b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com