Weaving machine shuttle and weaving machine applying same

A net weaving machine and shuttle technology, which is applied in the field of net weaving machines, can solve problems such as heavy weight, high running speed, and the failure of the net weaving machine to work normally, and achieve the effects of increasing life expectancy, reducing quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

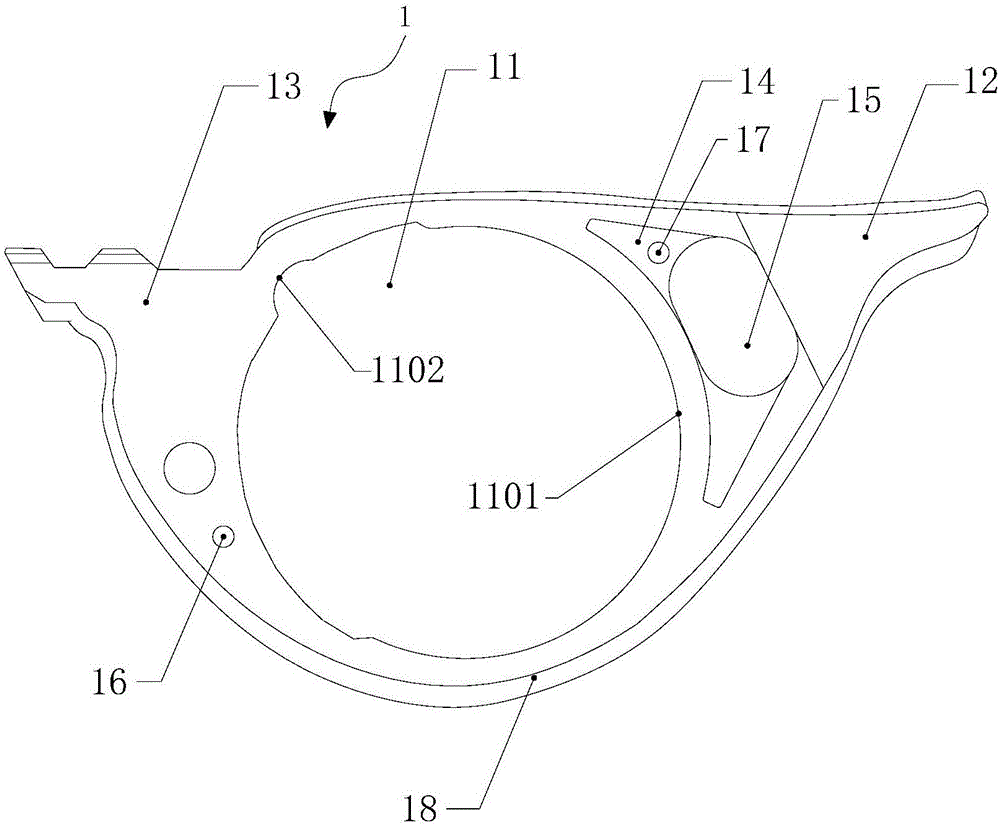

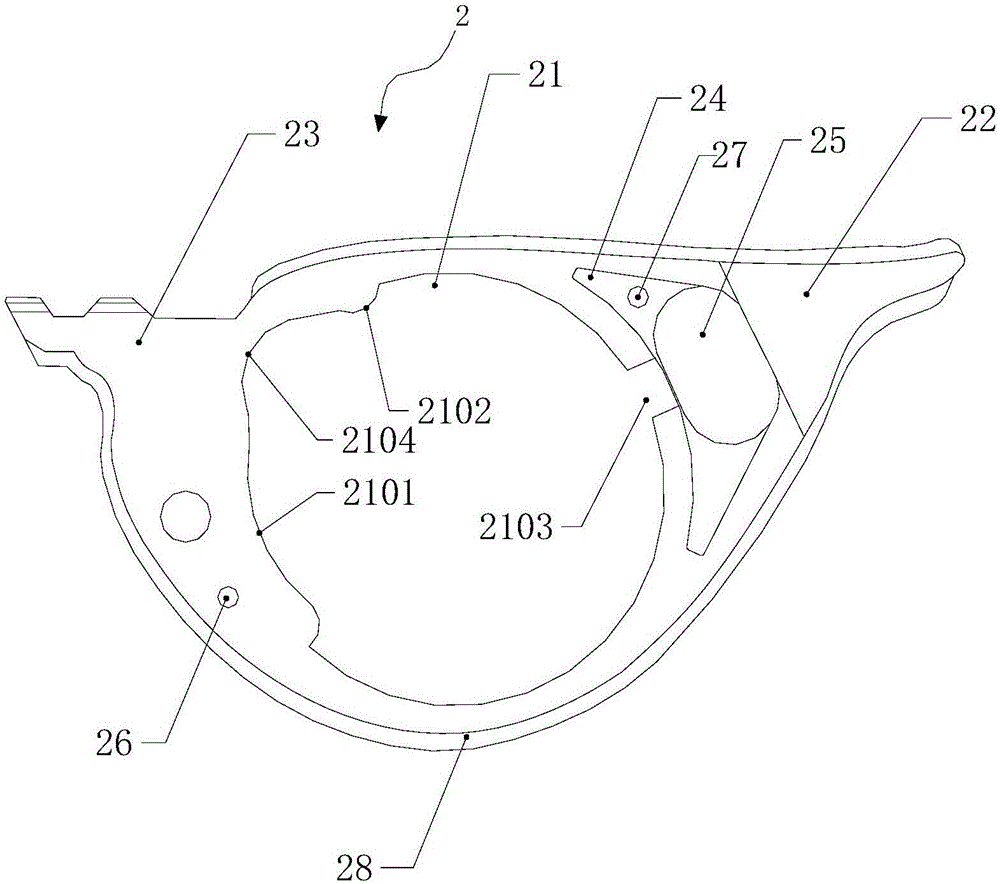

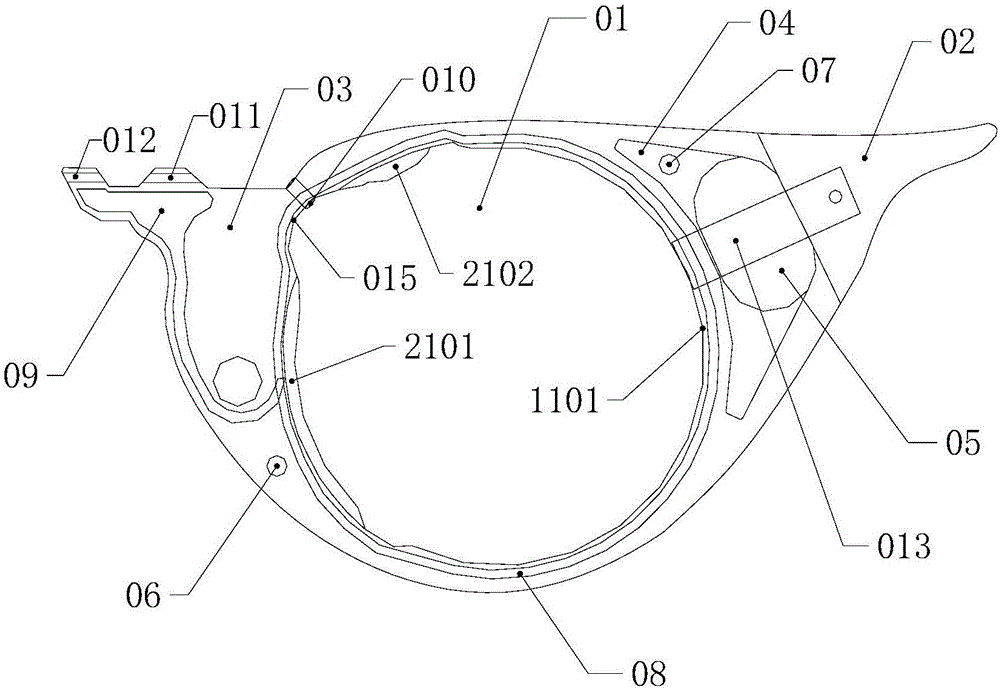

[0019] refer to Figure 1 to Figure 4 , the present invention provides a net weaving machine shuttle, including a first sheet 1 and a second sheet 2 with a circular opening structure, the first sheet 1 includes a middle part with a circular first opening 11, located at the second A first head 12 at one end of the opening 11 and a first tail 13 at the other end of the first opening 11, the second sheet 2 includes a middle part with a circular second opening 21, a The second head 22 and the second tail 23 positioned at the other end of the second opening 21, the first sheet 1 and the second sheet 2 are made of stainless steel, the outer edge of the first sheet 1 and the second sheet 2 The first head 12 corresponds to the second head 22 to form a head area 02, the first opening 11 corresponds to the second opening 21 to form an opening 01, and the opening 01 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com