Linear pulley-block hoist

A pulley block and gate hoist technology, applied in coastline protection, water conservancy engineering, sea area engineering, etc., can solve the problems of large working bridge width, high manufacturing cost, and increased overall manufacturing cost of the gate body, achieving compact layout, compact structure, Ease of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

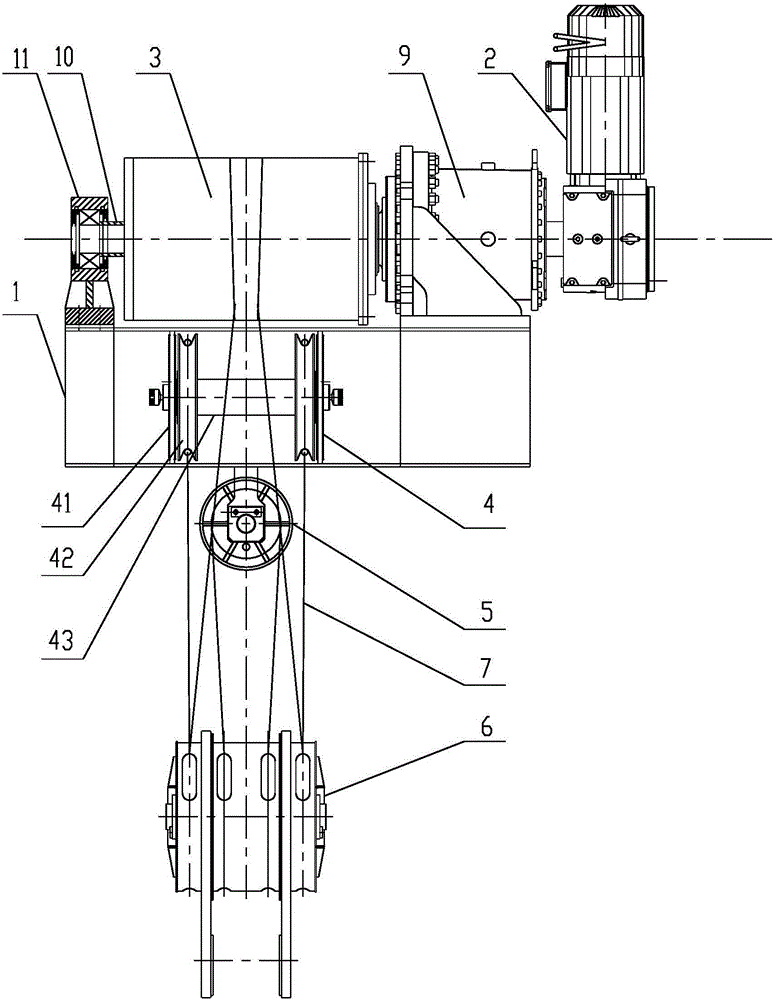

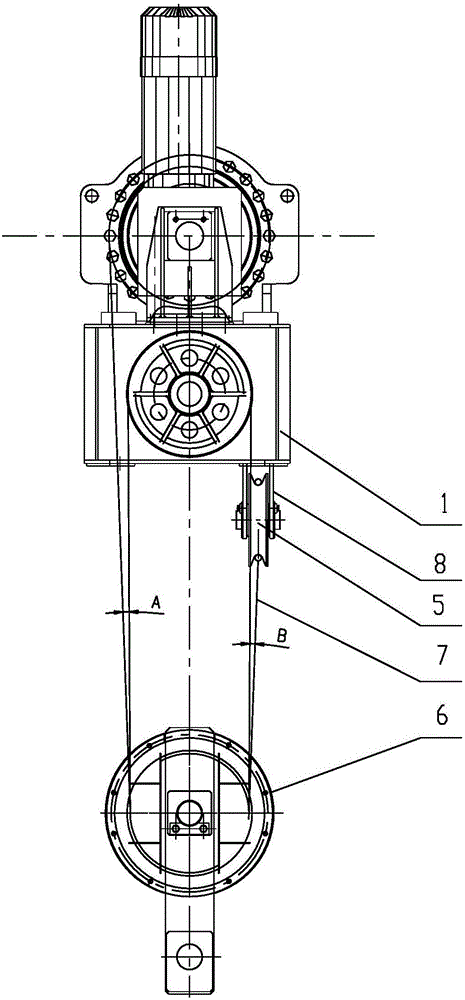

[0023] The invention is like Figure 1-3 As shown, it includes a frame 1. The top of the frame 1 is provided with a reel 3 driven by a motor 2, a fixed pulley block 4 is provided in the frame 1, and a balance pulley 5 is provided at the bottom of the frame. A movable pulley block 6 is provided under the frame, and both ends of the reel are respectively provided with support shafts 10, the motor 2 is connected to a support shaft of the reel through a reducer 9, and the other support shaft of the reel is connected to the machine through a bearing seat 11. On the rack, the reel can rotate reliably;

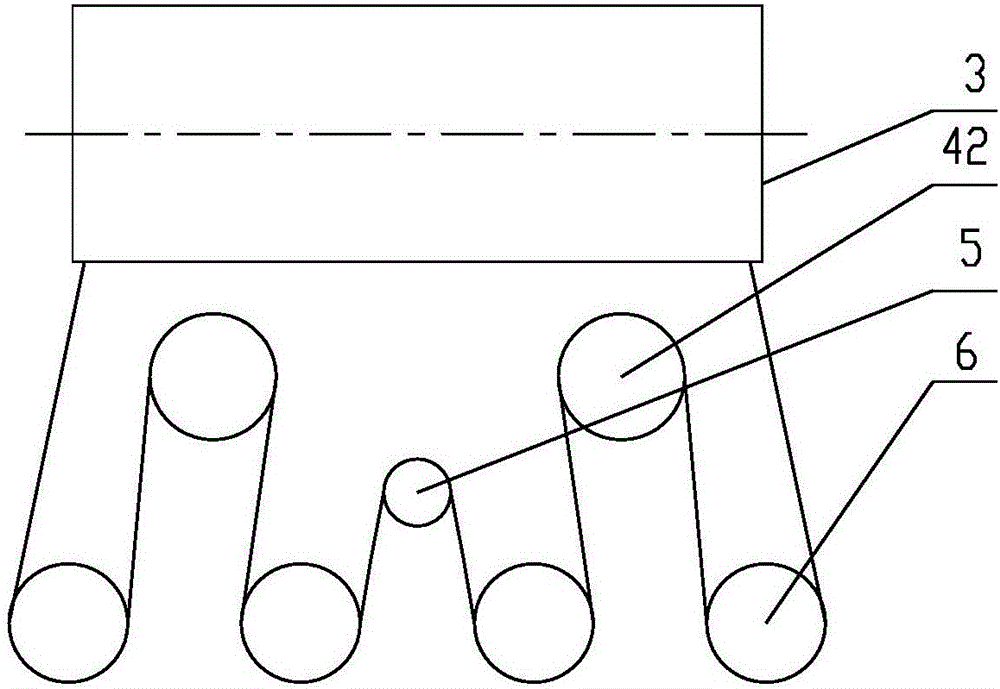

[0024] The two ends of the reel 3 are respectively wound and connected with the movable pulley group 6, the fixed pulley group 4 and the balance pulley 5 through the same wire rope 7; the connection sequence of the wire rope is: reel→movement pulley group→fixed pulley one→movement pulley group→balance pulley→ Movable pulley group→fixed pulley 2→moving pulley group→reel.

[0025] The cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com