Inertial electrical eddy current tuning and damping device

A damping device and eddy current technology, applied in bridge parts, bridge construction, building components, etc., can solve the problems of inconvenient adjustment of the tuning frequency of the damping device, increased structural load safety hazards, and large mass block volume. The effect of reducing quality and excellent energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

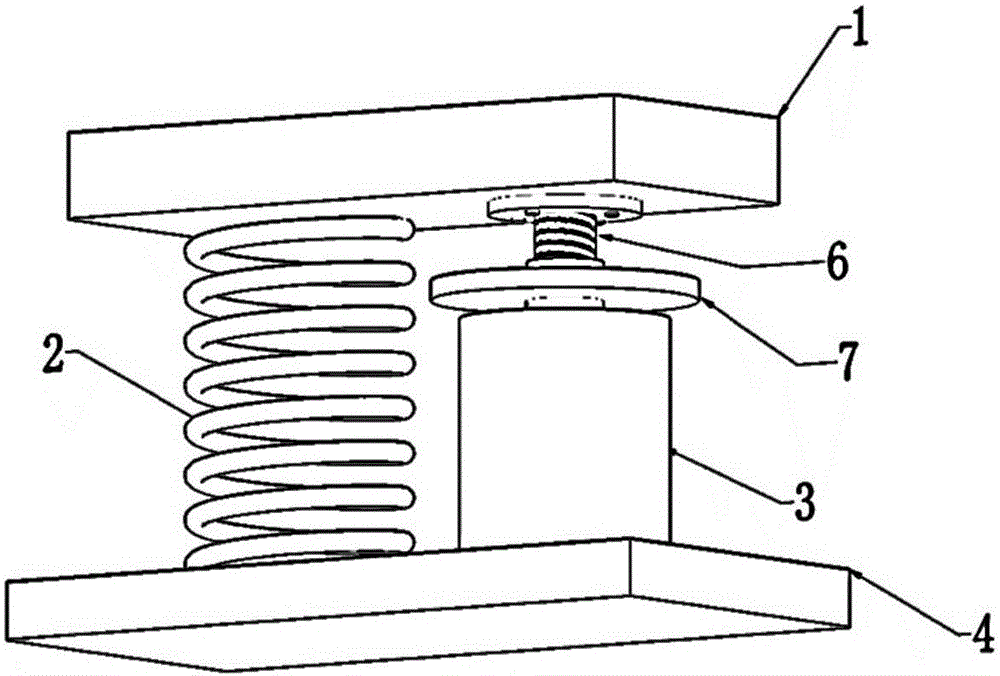

[0030] Such as Figure 1-2 As shown, an inertial eddy current tuning damping device, the device includes a mass block (1), a vertical spring (2), an acceleration type eddy current inertia damper (3), a connecting structure (4),

[0031] The spring (2) and the acceleration type eddy current inertia damper (3) are arranged in parallel between the connecting structure (4) and the mass block (1); the spring (2) plays a role of mass tuning.

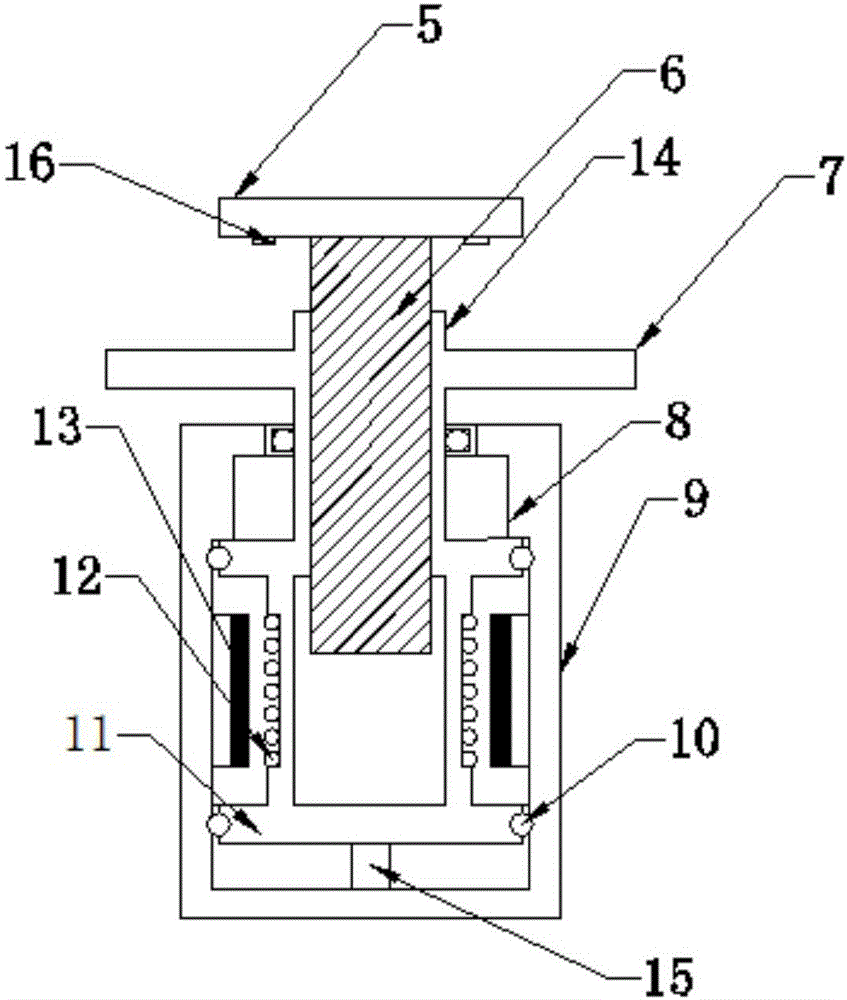

[0032] Such as figure 2 As shown: an acceleration type eddy current inertia damper 3 is provided in this embodiment, including a connecting plate 5, a ball screw 6, a rotating mass 7, an outer cylinder slot 8, an outer cylinder 9, balls 10, a rotating inner cylinder 11, Coil 12, annular permanent magnet 13, rotating nut 14, rotating bearing 15 and connecting bolt 16.

[0033] A certain number and form of rotating masses 7 are fixedly arranged on the outside of the rotating nut 14. The rotating nut 14 and the rotating inner cylinder 11 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com