Cold-formed thin-walled steel house interior wall reinforcement components

A technology of cold-formed thin-walled steel and reinforced components, which is applied to walls, building components, buildings, etc., can solve the problems of limited popularization and application and difficult installation of wall panels, and achieve simple processing technology, improved shear resistance, and bending resistance. The effect of capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

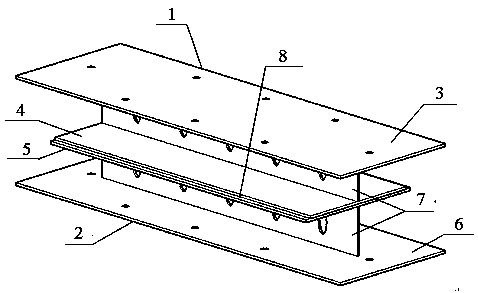

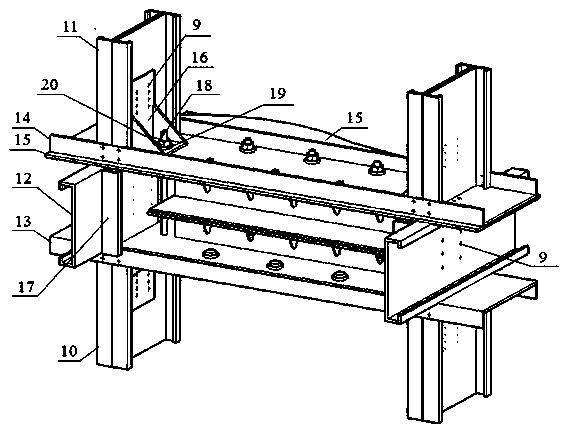

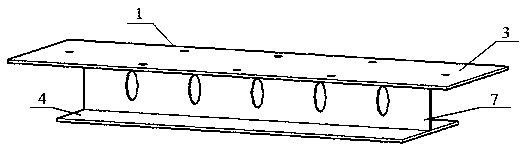

[0037] Comprising beams, trusses, and floor panels that cooperate with each other:

[0038] In order to improve the bearing capacity of the column, the column is composed of two C-shaped steels that are closely attached back to back and fixed with self-tapping screws 9, including the lower column 10 and the upper column 11;

[0039] The beam includes a C-shaped steel floor beam 12, a U-shaped steel roof beam 13 of the lower house with downward openings connecting two adjacent columns and a U-shaped steel bottom beam 14 of the upper house with an upward opening;

[0040] The floor structure board 15 is made of galvanized steel sheet on the bottom layer and bamboo plywood on the upper layer through glue, and there are bolt holes on it;

[0041] and:

[0042] There is an anti-extraction element 16 composed of a bottom plate, a back plate and a side plate. The bottom plate is provided with bolt holes and the back plate is provided with self-tapping screw holes.

[0043] C-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com