Well logging method capable of storing relative flow rate

A technology related to flow and well logging, applied in construction and other directions, can solve the problems of logging accuracy, low water injection, and easy to be affected by formation, to improve measurement accuracy, improve measurement accuracy, and eliminate data errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

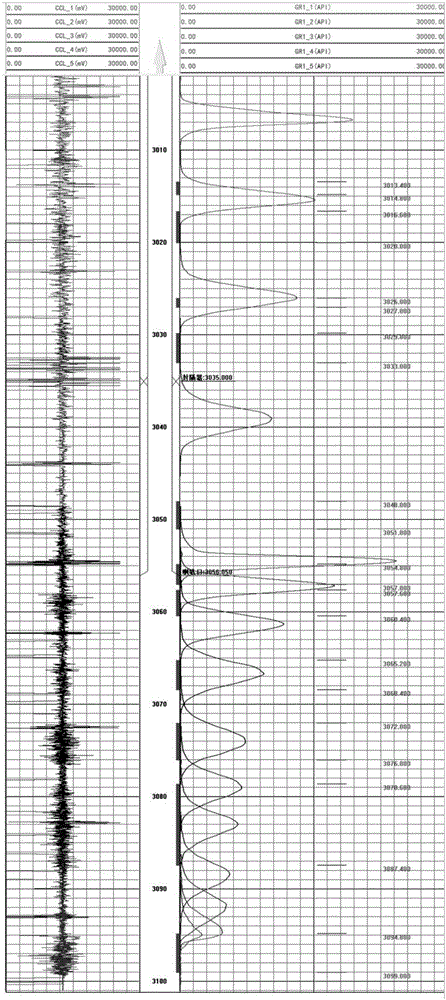

[0037] Well: 1

[0038] The basic data of the well condition of a high-pressure and low-injection water injection well in North China are as follows:

[0039] Perforated section: 2940.3-3208.6m; total effective thickness: 36.4m / 11 layers; casing size and depth: 139.7mm×2061.63m; artificial well bottom: 3220.3m; oil pressure: 28.4MPa, water injection pump pressure 29MPa, Daily injection volume: 10m 3 / sky.

[0040] The specific method of using steel wire logging is as follows:

[0041] Step (1): According to the basic data of the well to be measured (total effective thickness, casing size and depth, ball seat size and depth, artificial bottom hole depth, daily injection rate), the depth of the construction well section and the depth of the perforated well section are set The three parameters measure the working time of the meter and the release start time of the releaser, and synchronize the clock on the meter with the clock on the computer, the tracer strength stored in the...

Embodiment 2

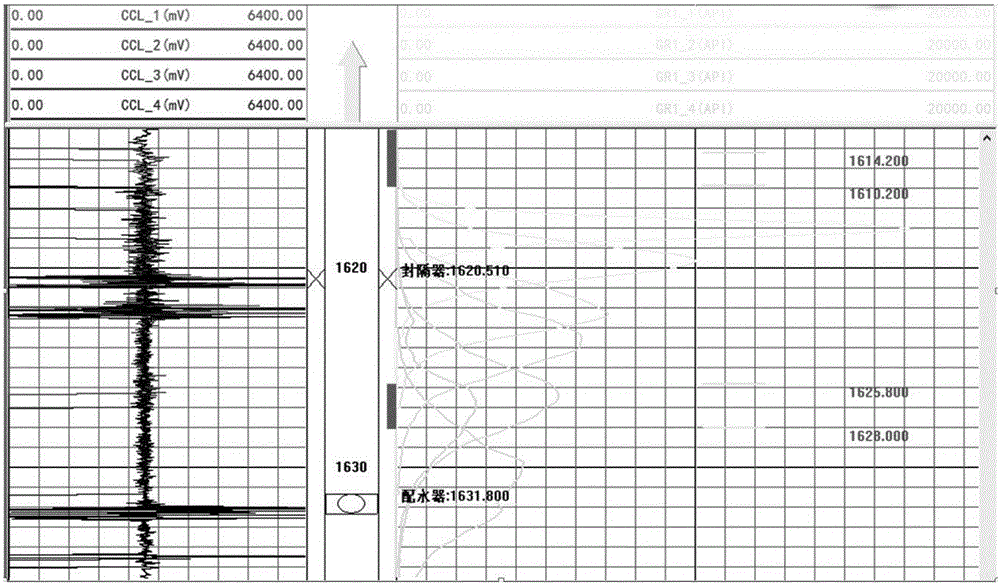

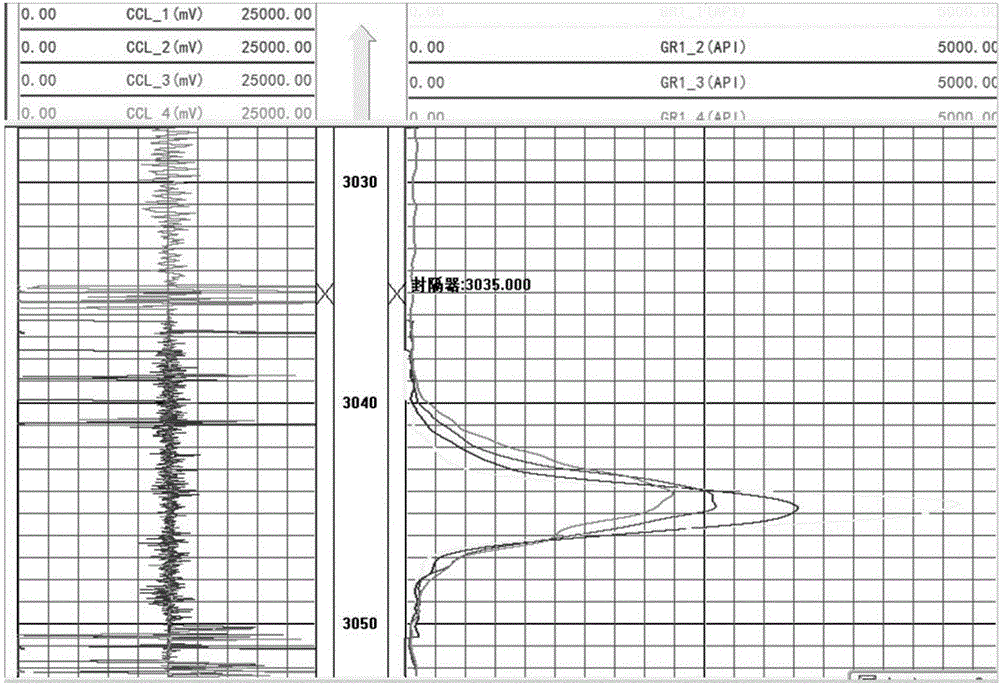

[0049] Well 2: The oil pressure of this well is 11.5MPa, and the water injection flow rate is 50 cubic meters per day. isolation, so that water injection can be finely controlled for each well section);

[0050] Steel wire related flow method: The construction steps are as above, after measuring the static temperature (basic curve), then start to measure the related flow three times (one measurement for each faucet, each measurement releases 15 ml of tracer, and a total of 45 ml of tracer is released for three times) After each release of the tracer, the flow meter is lifted up and down to measure the relevant flow rate, and the total measurement is three times).

[0051] After the measurement, the three sets of related data were merged, and the water absorption of the third faucet at the bottom (the main water absorption part of the well) was analyzed this time.

[0052] The merged curve is shown in 2. There is no leakage during the measurement process of the well, so the ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com