Construction method applied to frozen shaft safe and rapid excavating large and thick expansive clay layer

A technology of expanded clay and construction method, which is used in earth-moving drilling, shaft equipment, well sinking, etc., can solve the problems of complex stress structure and large borehole wall stress, and achieves economical efficiency, improved work efficiency and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

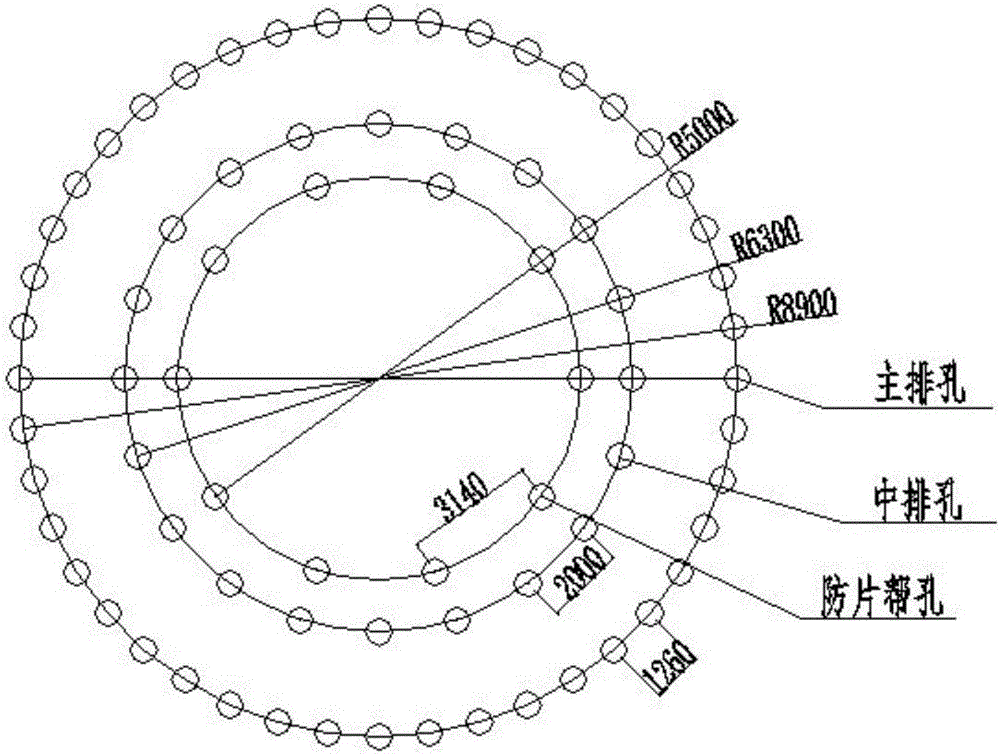

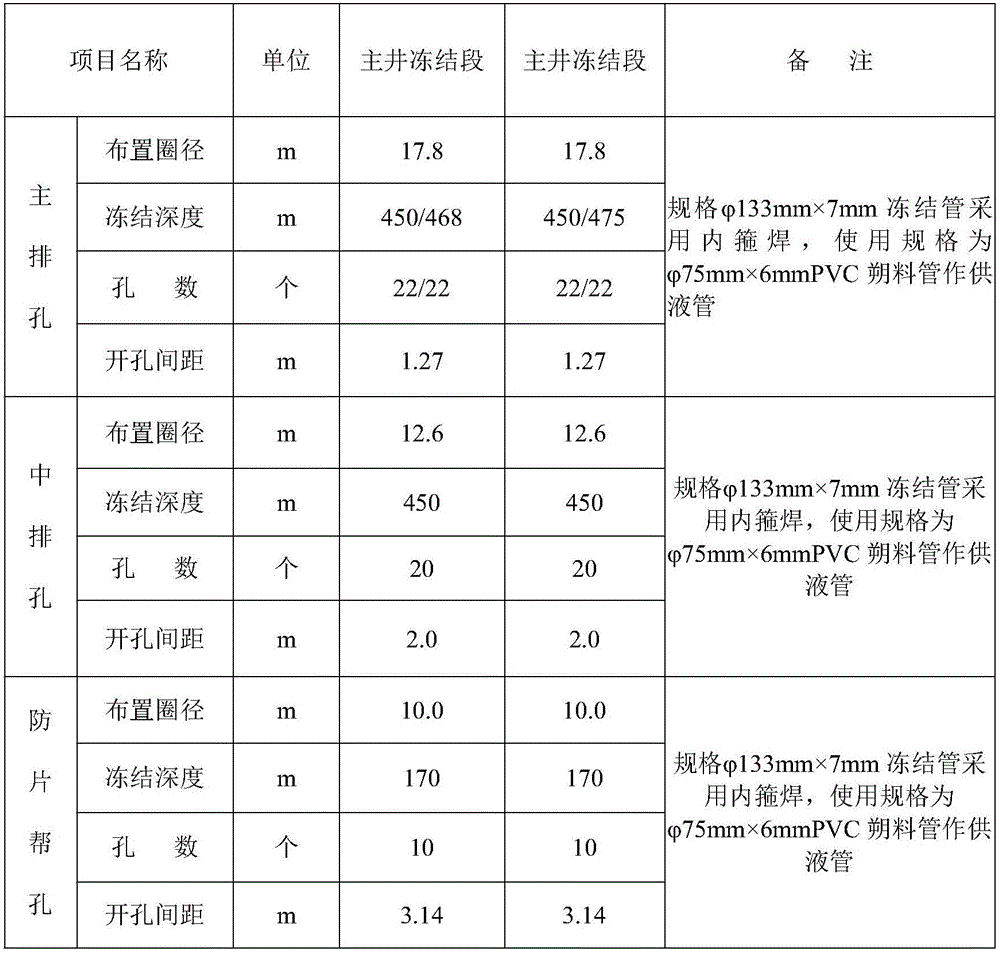

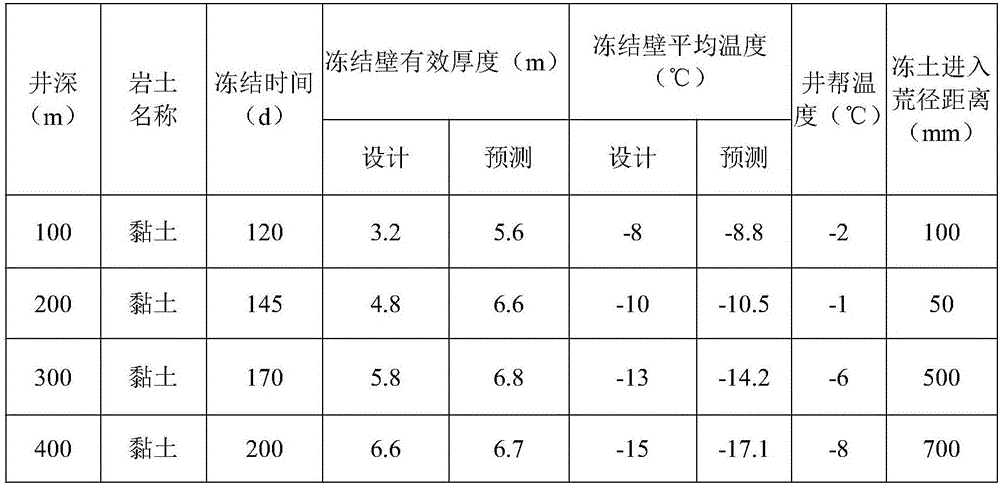

[0015] Such as figure 1 As mentioned above, the present invention is a new technology for safe and rapid excavation of frozen shafts through huge and large expansive clay layers. The following steps are followed: 1. Determine the center and outer edge of the main and auxiliary shafts according to the design drawings, and mark them with white ash. ② According to figure 1 In the main and auxiliary shaft wellbore freezing hole layout plan, the main row of holes, the middle row of holes, the layout of the anti-slab holes, the circle diameter, the number of holes, the hole spacing and other data accurately determine the drilling position, and draw the circle with red paint. Drilling is carried out according to the freezing depth in Table 1, the main and auxiliary wellbore freezing hole layout parameter design table. ③ After the drilling is completed, check each hole to see if it meets the requirements. ④ After the drilling inspection meets the requirements, install the freezing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com