A tunnel waterproof partition structure using spray waterproof technology and its implementation method

An implementation method and tunnel technology, which are applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of incomplete waterproof zoning of composite lining tunnels, and achieve effective governance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

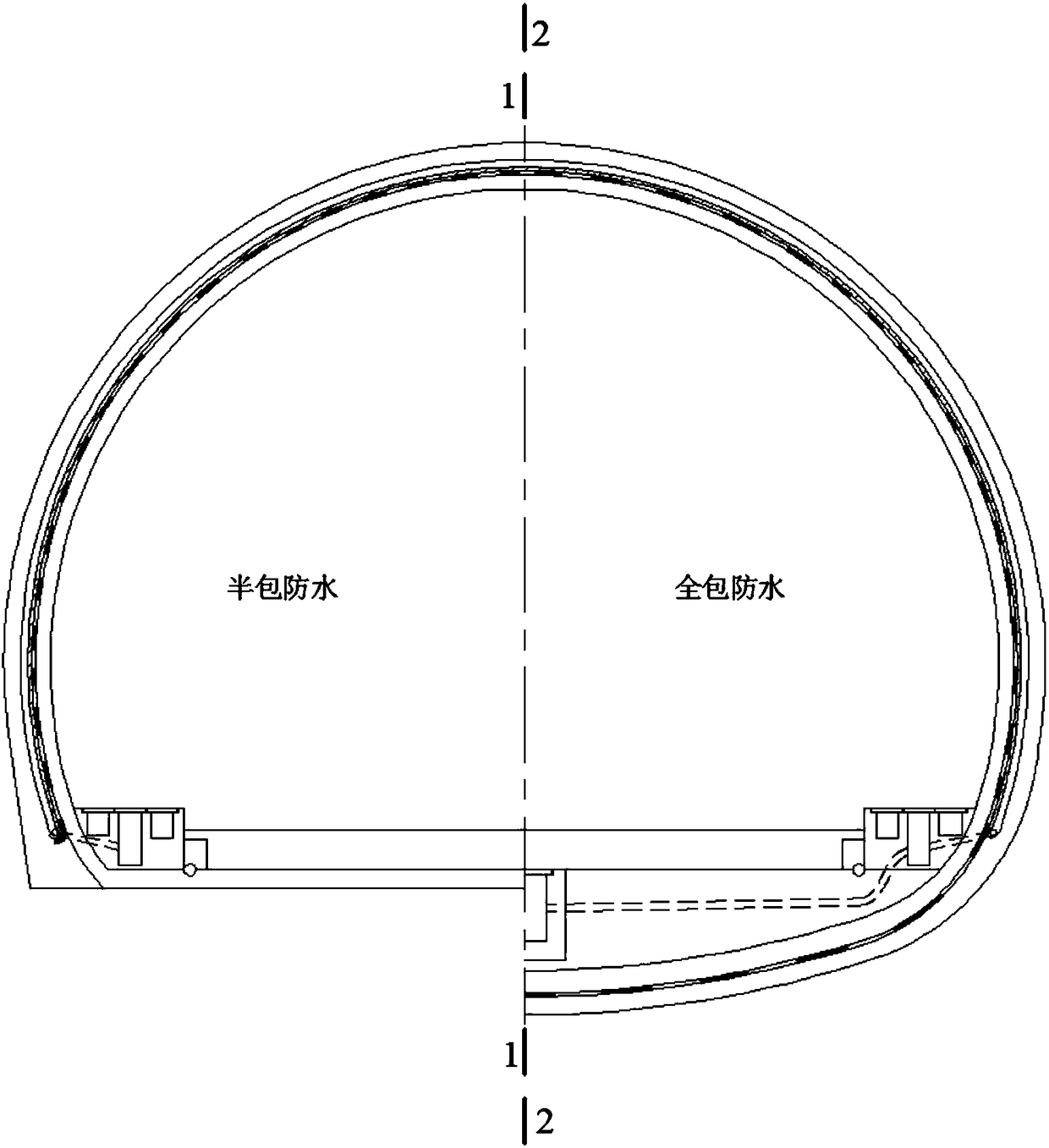

[0033] Embodiment 1: as image 3 The structure on the left in the form and Figure 4 ( image 3 As shown in 1-1 section in ), the waterproof partition can be realized in the tunnel waterproof system of the half-pack waterproof type.

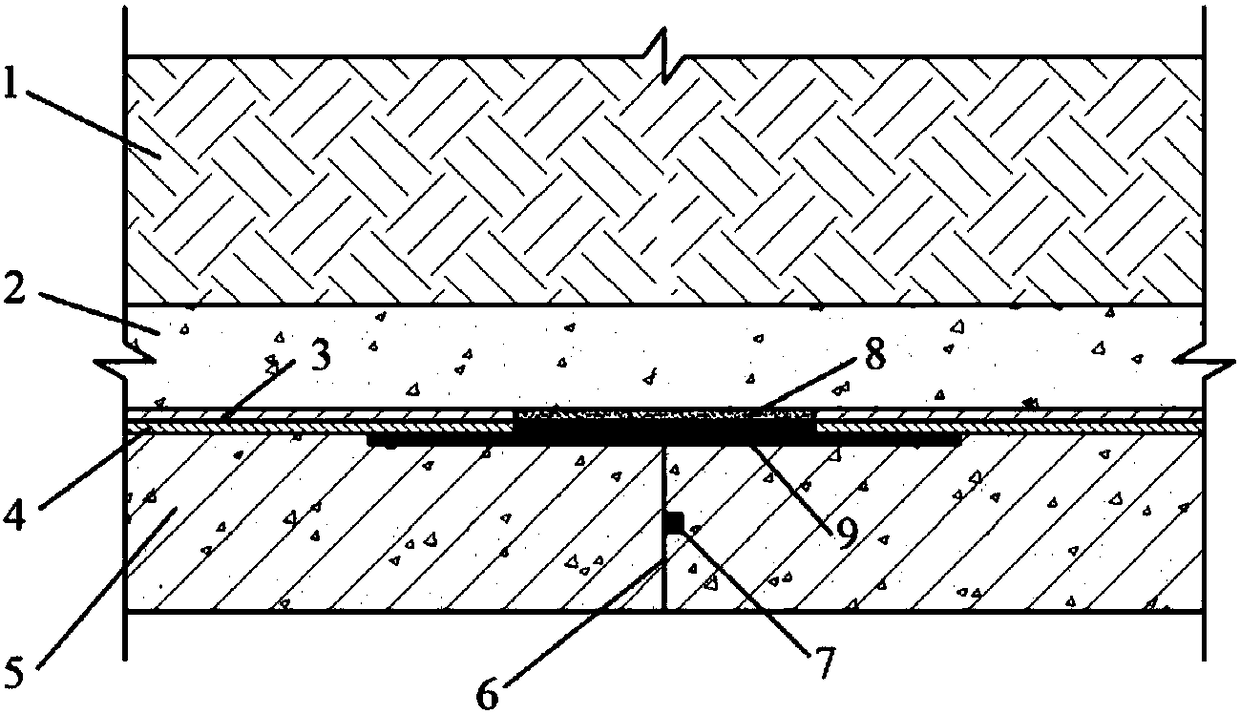

[0034] The construction type of the tunnel waterproof partition in this embodiment is: divide the tunnel waterproof partition by the construction joint 6 position of the secondary lining 5 of the composite lining tunnel, and leave a certain width range between adjacent waterproof partitions to set waterproof partition measures; from Tunnel waterproof zoning measures shall be set in the range from the vault of the tunnel to the arch feet on both sides, and the tunnel waterproof zoning measures shall not be set in the inverted arch because there is no waterproof layer; When it is not serious, use such asfigure 1 Waterproof partition measures without grouting anti-seepage ring shown ( Figure 4 Waterproof zoning measures on the left side in the a...

Embodiment approach

[0035] Its implementation method is as follows:

[0036] (1) After the initial support construction of the tunnel, determine the position of the tunnel waterproof partition and the range of the partition according to the position of the construction joint 6 of the secondary lining 5;

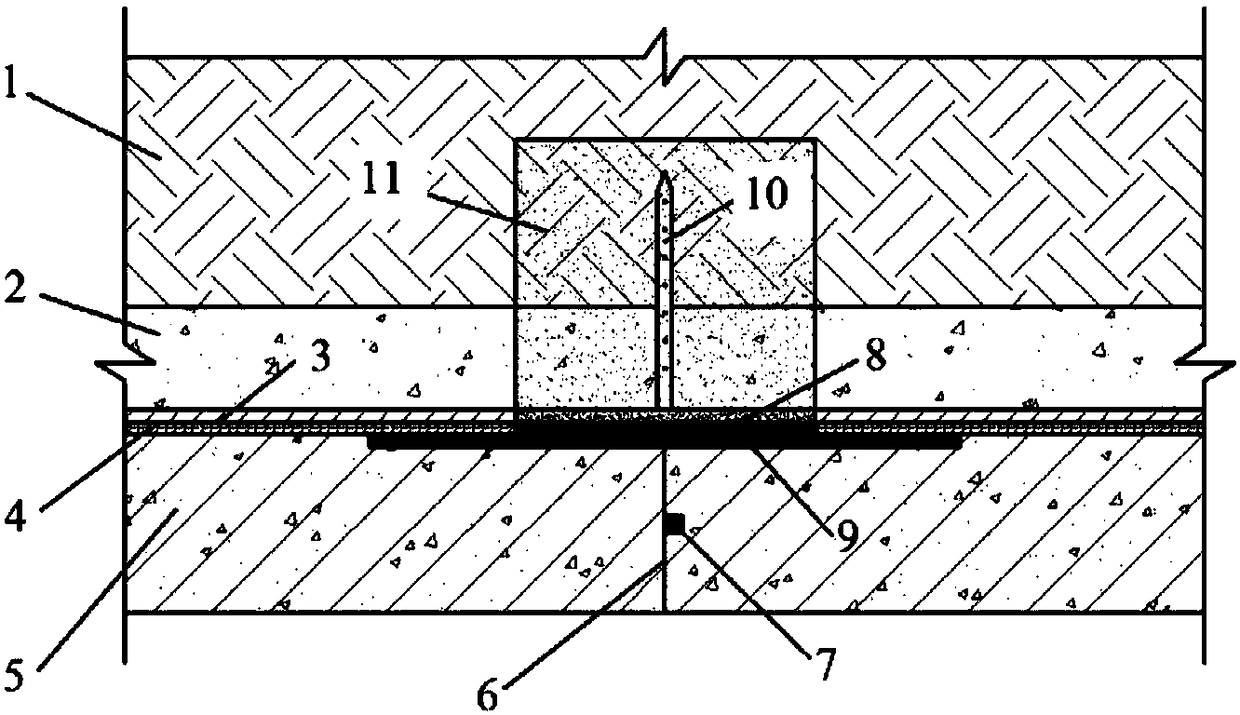

[0037] (2) Depending on the conditions of the surrounding rock and groundwater, decide whether to implement the grouting pipe 10 and the grouting anti-seepage ring 11 in the waterproof partition;

[0038] (3) In the range from the arch top of the tunnel to the arch feet on both sides, apply a waterproof mortar leveling layer 8 for the waterproof partition parts;

[0039] (4) Lay non-woven fabric 3 and waterproof layer 4 in the first waterproof section from the vault of the tunnel to the arch feet on both sides;

[0040] (5) Spraying the waterproof layer 9 at the location of the waterproof partition;

[0041] (6) Pouring the secondary lining 5 of the first waterproof section and implementing co...

Embodiment 2

[0043] Embodiment 2: as image 3 The structure on the right in the form and Figure 5 ( image 3 As shown in Section 2-2 in ), the waterproof partition can be realized in the tunnel waterproof system of the all-inclusive waterproof type.

[0044] The structure type of the tunnel waterproof partition in this embodiment is: divide the tunnel waterproof partition by the construction joint 6 position of the secondary lining 5 of the composite lining tunnel, and leave a certain width range between adjacent waterproof partitions to set waterproof partition measures; Tunnel waterproof zoning measures are set up in the entire ring of the tunnel; when the surrounding rock is good or the groundwater leakage at the base of the initial support 6 is not serious, adopt the following measures: figure 1 Waterproof partition measures without grouting anti-seepage ring shown ( Figure 5 Waterproof zoning measures on the left side in the above); when the surrounding rock is relatively broken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com