Screw pump stator for preparing polyacrylonitrile matrix

A technology of polyacrylonitrile and pump stator, which is applied in the field of spinning, which can solve the problems of reducing the service life of the stator, polluting the polyacrylonitrile stock solution, and affecting the quality of fiber precursors, so as to achieve the effect of increasing the service life and not being easily broken and deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

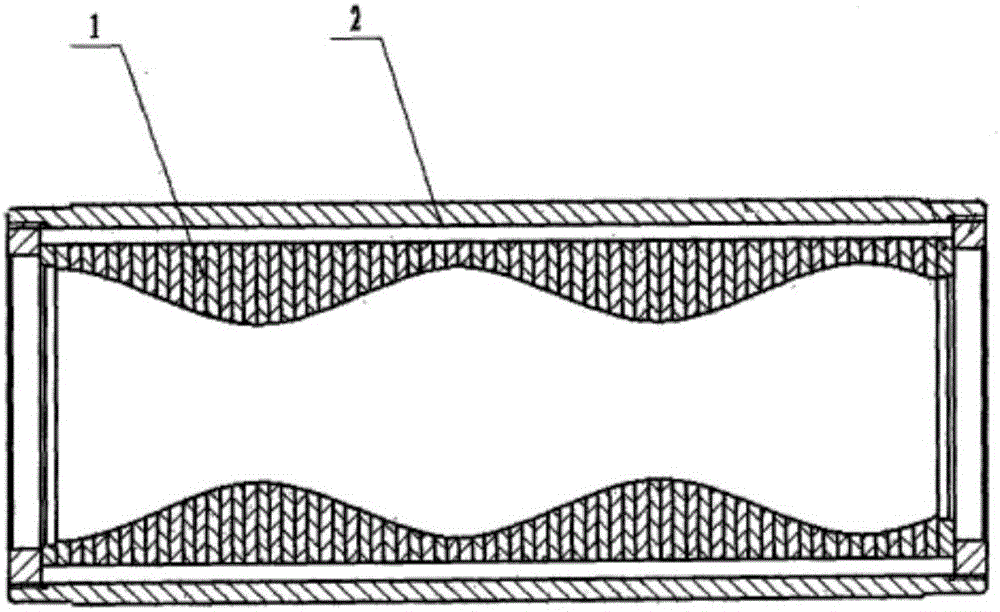

[0023] This embodiment provides a screw pump stator for making polyacrylonitrile stock solution, comprising a stator core 1 and a metal sleeve 2; the stator core 1 is installed inside the metal sleeve; the stator core 1 is made of organic silicon It is prepared by compounding with carbon fiber according to the mass ratio of 5:1; the length of the carbon fiber is 3mm.

[0024] Organosilicon composite material process: Silicone and carbon fiber are chopped, mixed and ground, and then vulcanized at a high temperature; the high temperature vulcanization temperature is 100°C-140°C.

Embodiment 2

[0026] This embodiment provides a screw pump stator for making polyacrylonitrile stock solution, including a stator core 1 and a metal sleeve 2; the stator core 1 is installed inside the metal sleeve; the stator core 1 is made of organic silicon and The carbon fiber is prepared by compounding according to the mass ratio of 12:1; the length of the carbon fiber is 10mm.

[0027] Organosilicon composite material process: Silicone and carbon fiber are chopped, mixed and ground, and then vulcanized at a high temperature; the high temperature vulcanization temperature is 100°C-140°C.

Embodiment 3

[0029] This embodiment provides a screw pump stator for making polyacrylonitrile stock solution, comprising a stator core 1 and a metal sleeve 2; the stator core 1 is installed inside the metal sleeve; the stator core 1 is made of organic silicon It is prepared by compounding with carbon fiber according to the mass ratio of 7:1; the length of the carbon fiber is 5mm.

[0030] Organosilicon composite material process: Silicone and carbon fiber are chopped, mixed and ground, and then vulcanized at a high temperature; the high temperature vulcanization temperature is 100°C-140°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com