Gear case output shaft coupling for 100% low floor vehicle and transmission method of gear case output shaft coupling

A low-floor vehicle and gear box technology, applied in the transmission system, axles, wheels and other directions of locomotives, can solve the problems of increasing the intermediate links of torque transmission, large installation space requirements, and increasing size space, etc., to achieve efficient transmission and reduce installation. Space requirements, effect of reducing axial dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

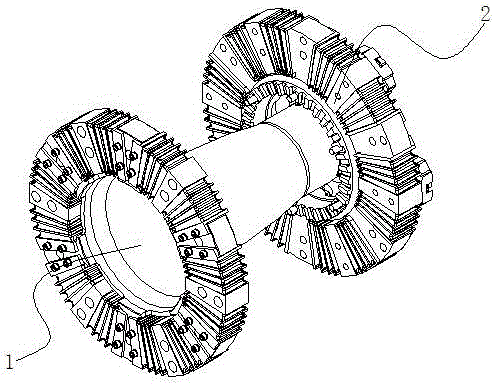

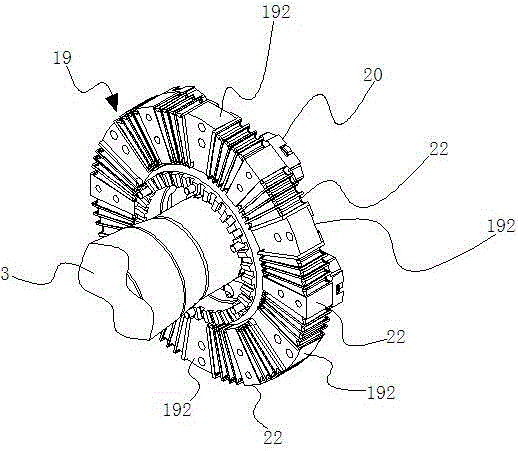

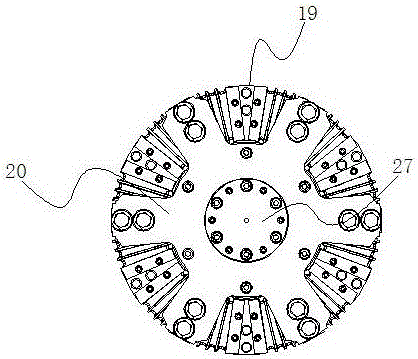

[0046] Embodiment 1: as Figure 1 to Figure 5 As shown, a 100% low-floor vehicle gearbox output coupling includes a transmission hollow shaft 1 and a gearbox transmission part 2, and the transmission hollow shaft 1 includes a hollow shaft 3 and a wheel drive disc arranged on one end of the hollow shaft 3 4. The transmission part 2 of the gearbox is connected to the other end of the hollow shaft 3, and the output shaft 5 of the gearbox is connected to the transmission part 2 of the gearbox. The hollow shaft 3 is in the shape of a hollow truncated cone. 3 on the side of the big end; the wheel 7 with the axle 6 is connected to the wheel drive disc 4, when the wheel 7 is connected to the wheel drive disc 4, the protruding part 711 on the outer side of the wheel is located in the big end of the hollow shaft 3 cavity. The applicant found in actual work that when the transmission hollow shaft is installed on the wheel, the protruding parts on the outside of the wheel will also affec...

Embodiment 2

[0063] Embodiment 2: as Figure 18 and Figure 19 As shown, compared with Embodiment 1, the difference is that the hollow shaft 3 is arranged in multiple sections along the axial direction of the hollow shaft 3 , and the outer peripheral surfaces of the multi-section hollow shaft 3 are arranged in sequence in a state of alternating straight surfaces 31 and inclined surfaces 32 . In this embodiment, the structure of the hollow shaft is further improved. The hollow shaft is arranged in a multi-section structure, and the outer diameter of the hollow shaft is gradually divided into sections from the big end of the hollow shaft to the small end of the hollow shaft along the axial direction of the hollow shaft. Reduced, this nonlinear structure can make the strength of the hollow shaft higher.

[0064] In this embodiment, the hollow shaft is arranged in five sections along the axial direction of the hollow shaft, including segmented hollow shaft one D1, segmented hollow shaft two D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com