Brake disc with gradient feature bionic coupling element and preparation method thereof

A technology of coupling unit and brake disc, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of accelerated brake disc thermal cracks, fatigue and inconsistent wear, unfavorable brake disc heat dissipation, etc. Anti-cracking performance, effect of retarding diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The proportions of aluminum oxide in each filled ring from the inside to the outside are 5%, 10%, 15%, 20% and 25% in sequence.

Embodiment 2

[0024] The proportions of aluminum oxide in each filled ring from the inside to the outside are 7.5%, 12.5%, 17.5%, 22.5% and 27.5%.

Embodiment 3

[0026] The proportions of aluminum oxide in each filled ring from the inside to the outside are 10%, 15%, 20%, 25% and 30% in sequence.

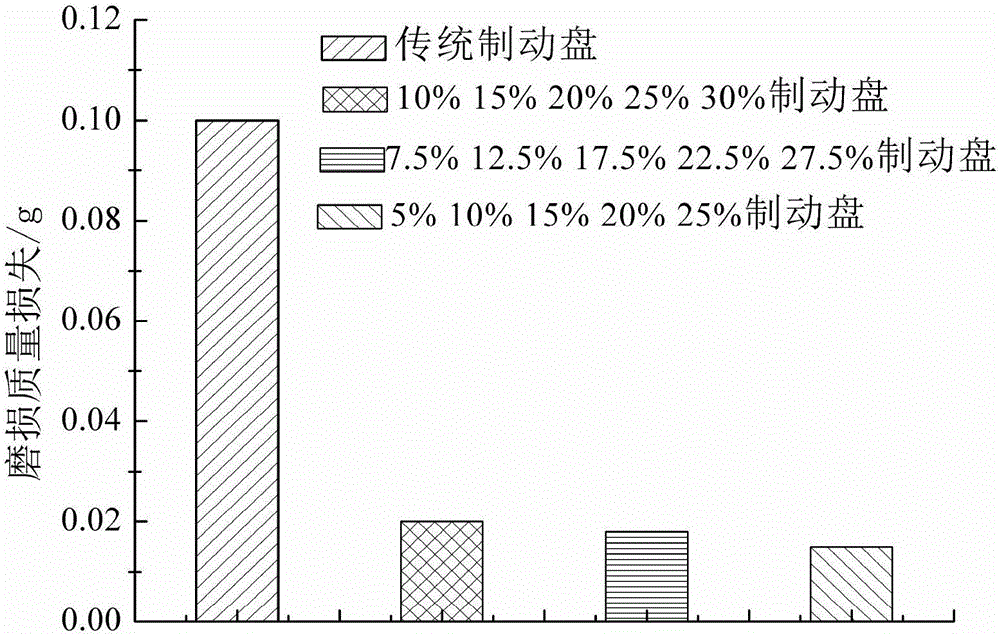

[0027] like image 3 As shown, after being used for 30 minutes under the same conditions, the wear amounts of Examples 1, 2 and 3 were 0.02g, 0.016g and 0.013g respectively; the wear amount of the conventional brake disc was 0.1g. It can be seen that the wear resistance of each embodiment is obviously better than that of the conventional brake disc, and among the embodiments, the wear resistance of embodiment 3 is the most superior.

[0028] The manufacturing method of the brake disc with gradient characteristic bionic coupling unit body is as follows:

[0029] Step 1. Drill a hole with a diameter of 65mm in the center of the base plate.

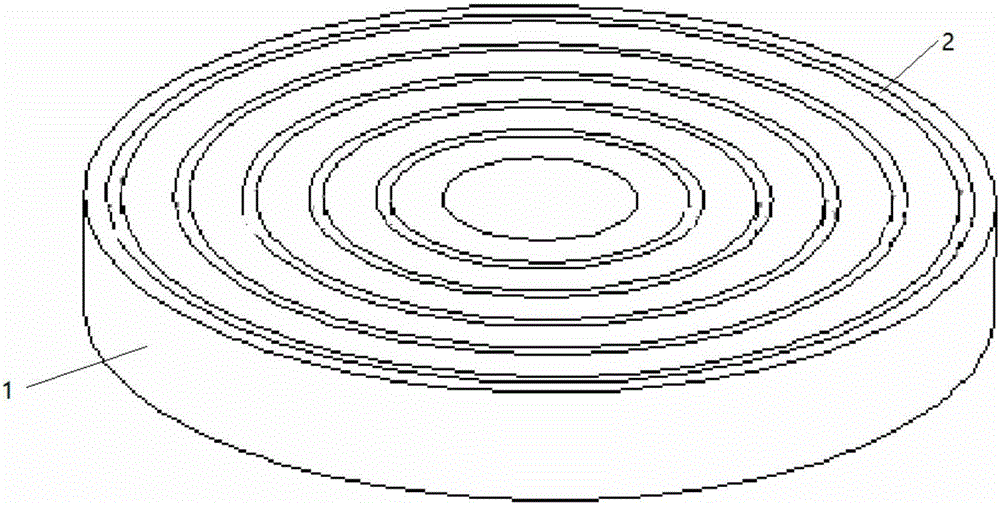

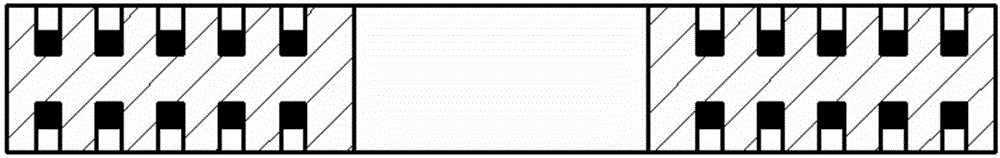

[0030] Step 2: Milling is used to process annular groove groups on both ends of the base plate 1 . The annular groove group is composed of five annular grooves of different sizes. The five annular groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com