Mini-type bistable-state self-locking valve

A bistable, self-locking valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of valve core stuck, low sealing reliability, easy to produce wear, etc., to ensure sealing reliability, avoid The effect of contact friction and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

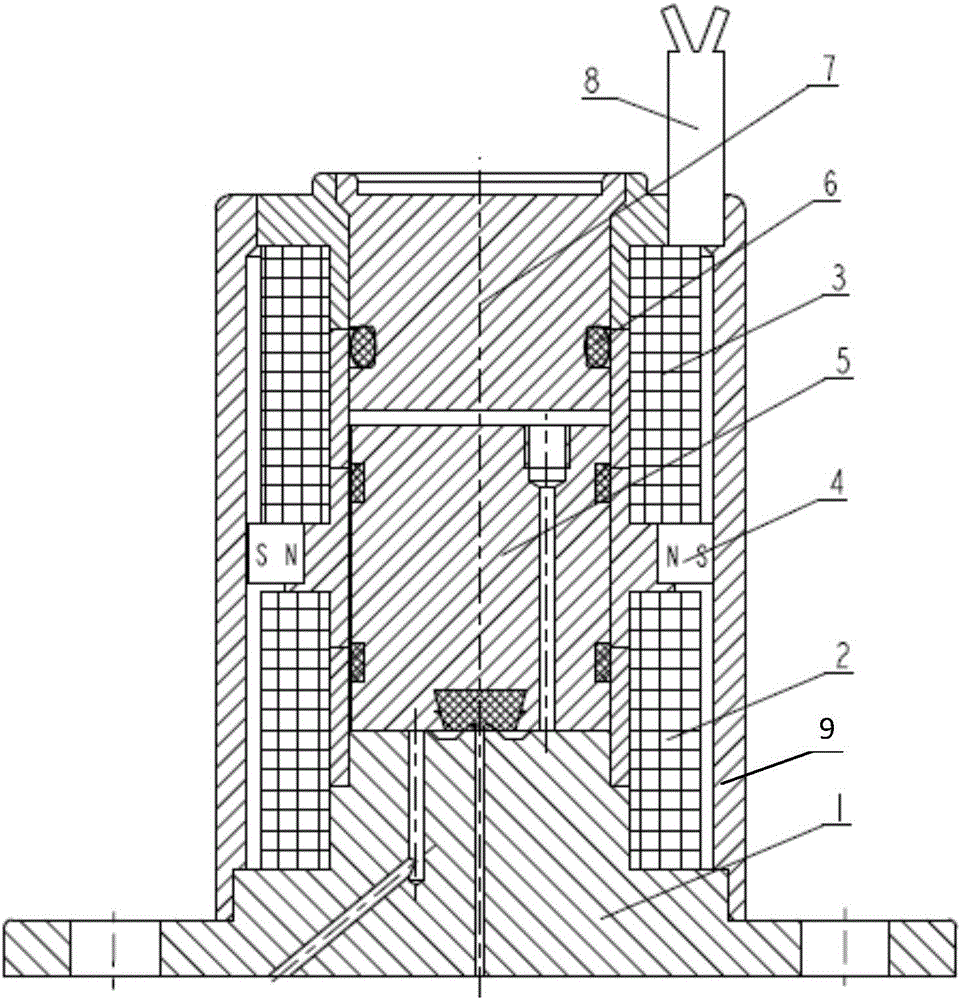

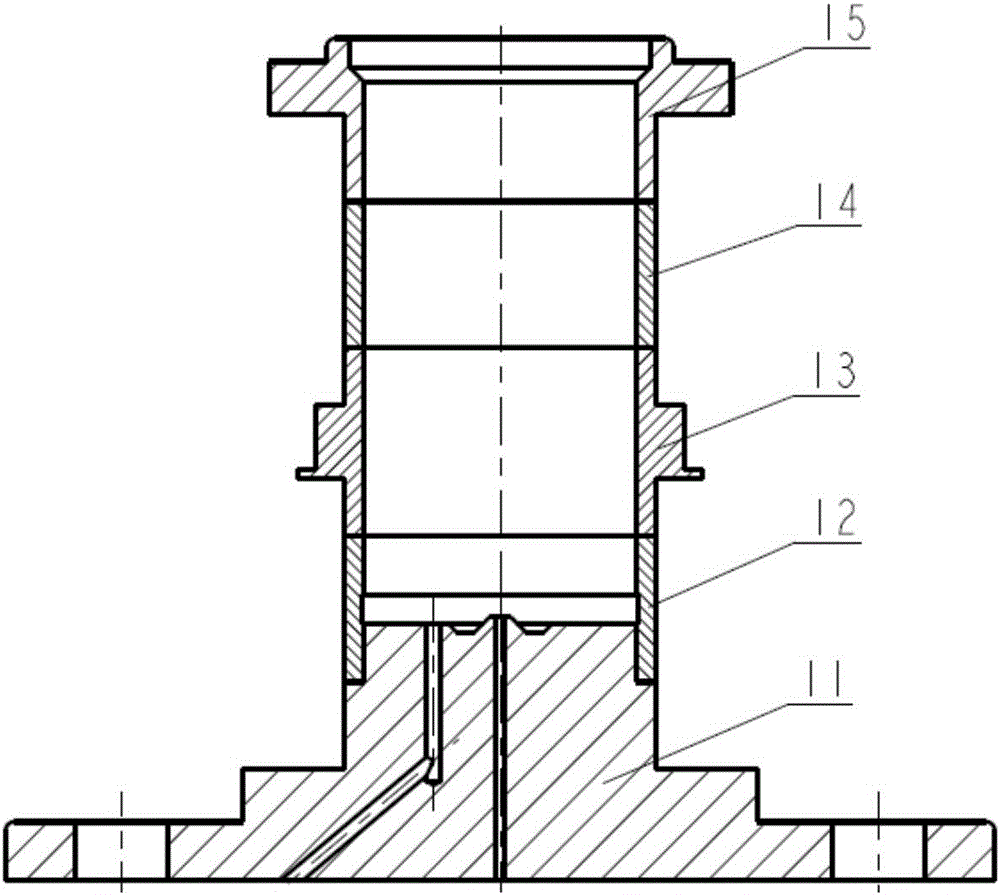

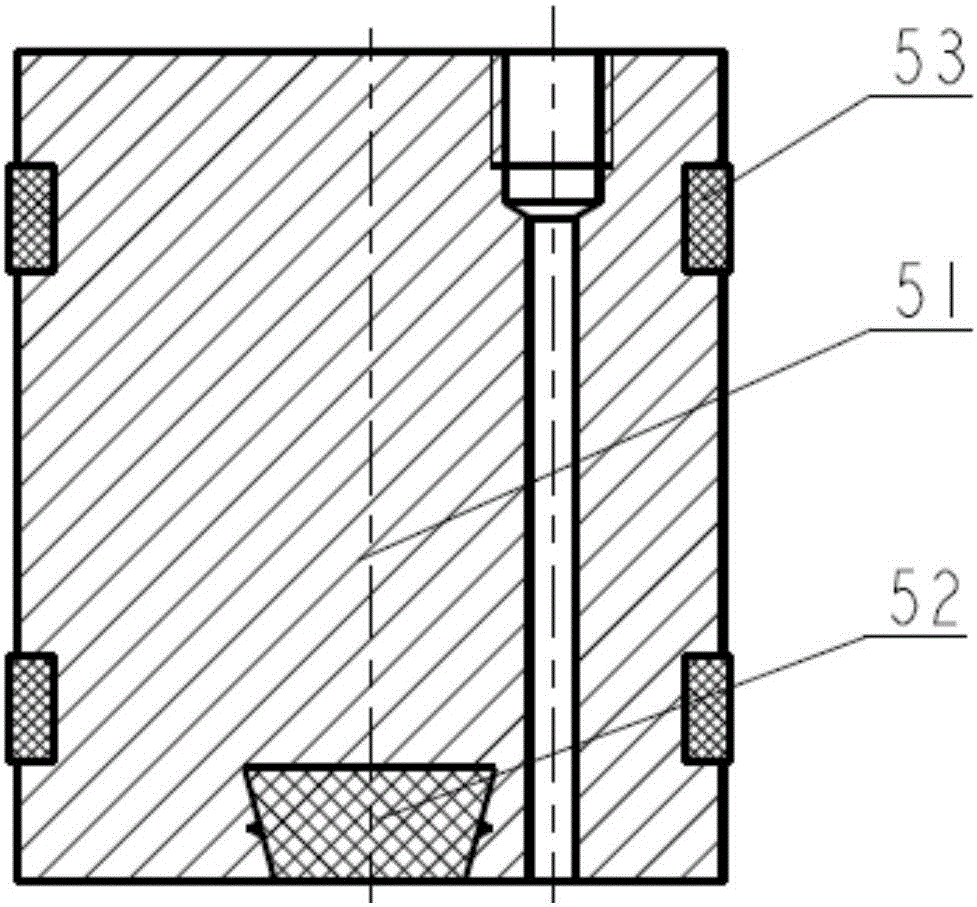

[0016] like figure 1 , figure 2 A miniature bistable self-locking valve is shown, including a valve body 1, a closed coil 2, an open coil 3, a permanent magnet 4, a valve core 5, a stopper 7, a wire 8 and a casing 9; the casing 9 is wrapped in the valve body 1 and the outside of the valve core 5, the iron stopper 7 and the valve core 5 are sequentially arranged in the upper inner cavity of the valve body 1, and the opening coil 3, permanent magnet 4, and closing coil 2 are sequentially arranged outside the valve body 1 along the axial direction In the groove; the valve body 1 includes a valve seat 11, a lower magnetic isolation ring 12, a magnetic conduction ring 13, an upper magnetic isolation ring 14 and a terminal 15 which are sequentially welded together by a vacuum electron beam; the valve core 5 Including a rubber block 52, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com