Corrosion-resistant non-metallic lined pipe section, pipeline and manufacturing method thereof

A manufacturing method and technology of corrosion-resistant alloys, which are used in pipeline protection, pipeline anti-corrosion/rust protection, pipes/pipe joints/pipe fittings, etc., can solve problems such as complicated connections and hidden dangers in connection technology, and achieve the solution of leakage risks and elimination. Safety hazard, high corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

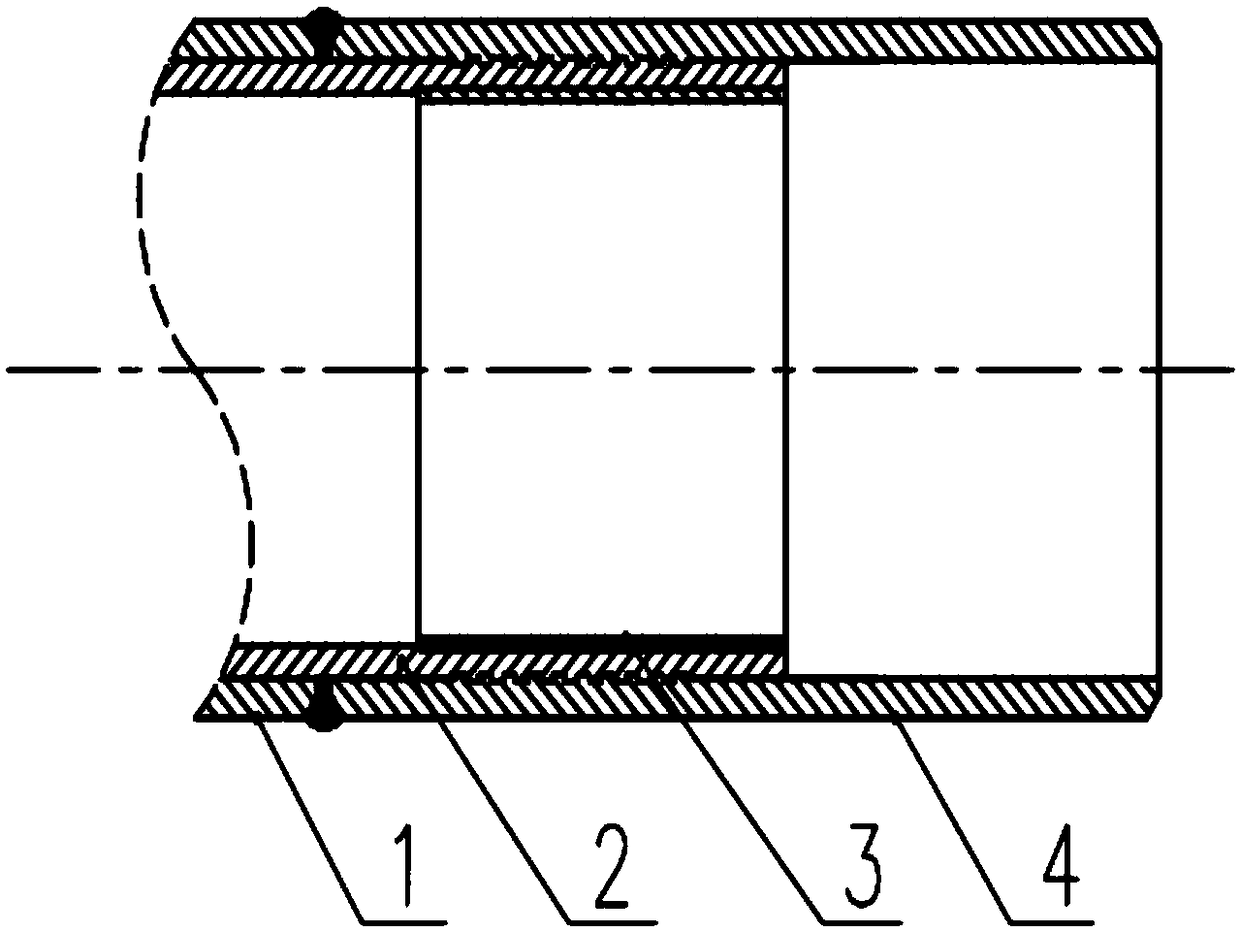

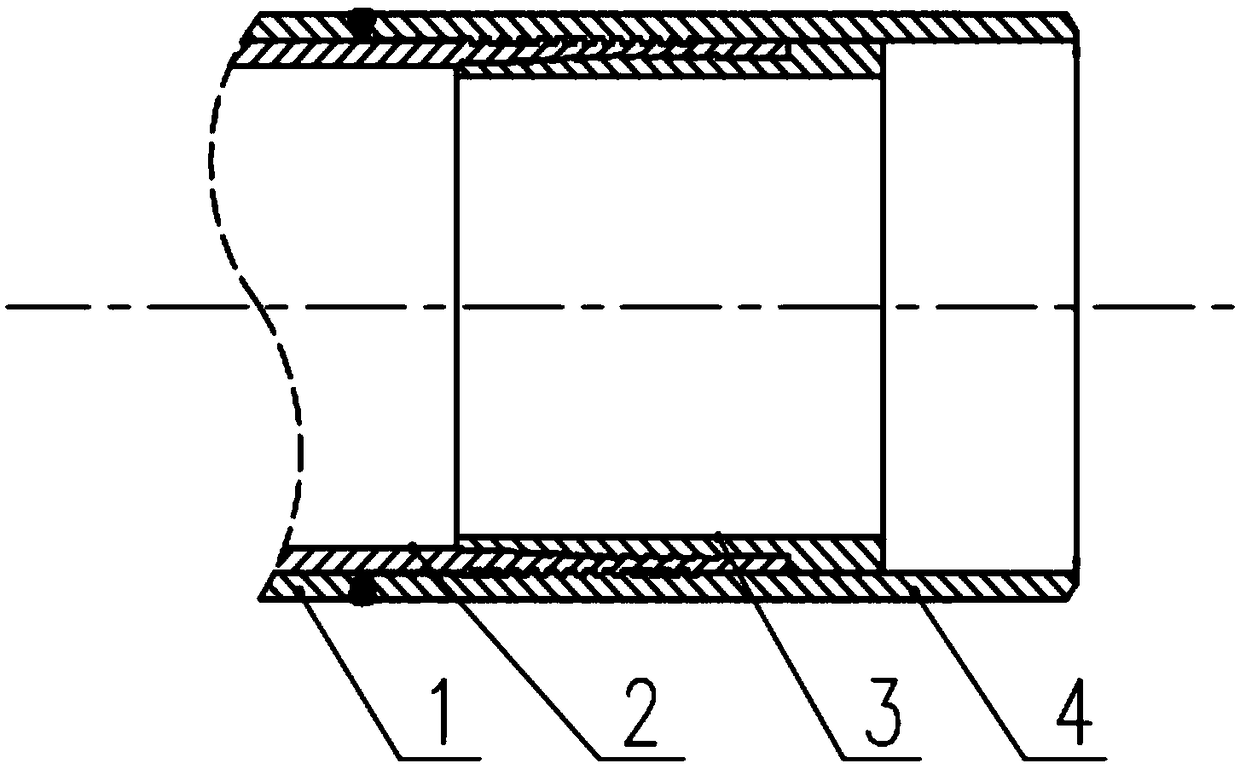

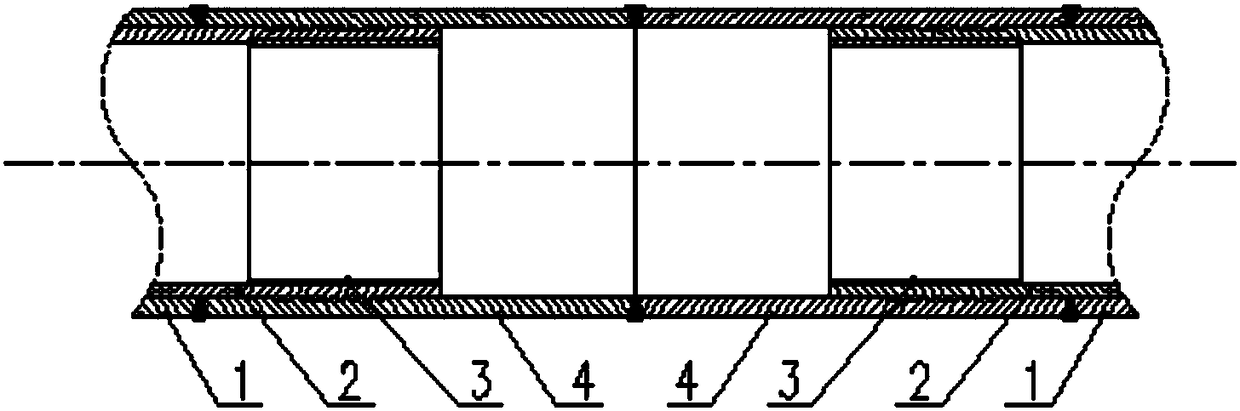

[0033] see figure 1 with figure 2 , a corrosion-resistant non-metallic lined pipe section, comprising an ordinary metal outer pipe 1, a non-metallic lining 2 arranged in the metal outer pipe 1, a corrosion-resistant alloy material transition pipe 4 welded at both ends of the metal outer pipe 1; the transition pipe The inner wall of 4 is provided with a plurality of annular grooves matching the compression ring 3, and the end of the non-metallic lining 2 is sealed and fixed in the middle of the inner wall of the transition pipe 4 through the anchoring effect of the compression ring and the plurality of annular grooves 3. The annular groove is preferably of rectangular cross-section. The corrosion-resistant alloy material is preferably stainless steel.

[0034] The manufacturing method of the corrosion-resistant non-metal lined pipe section comprises the following steps:

[0035] 1) A section of transition pipe 4 made of corrosion-resistant alloy material is respectively wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com