A narrow lap rolling seam welding method for high silicon thin gauge oriented silicon steel

A technology of oriented silicon steel and welding method, applied in the direction of roller electrode welding, welding equipment, resistance welding equipment, etc., can solve the problems of low production efficiency, poor welding quality, large heat, etc., to reduce production costs and improve weld quality. , the effect of high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

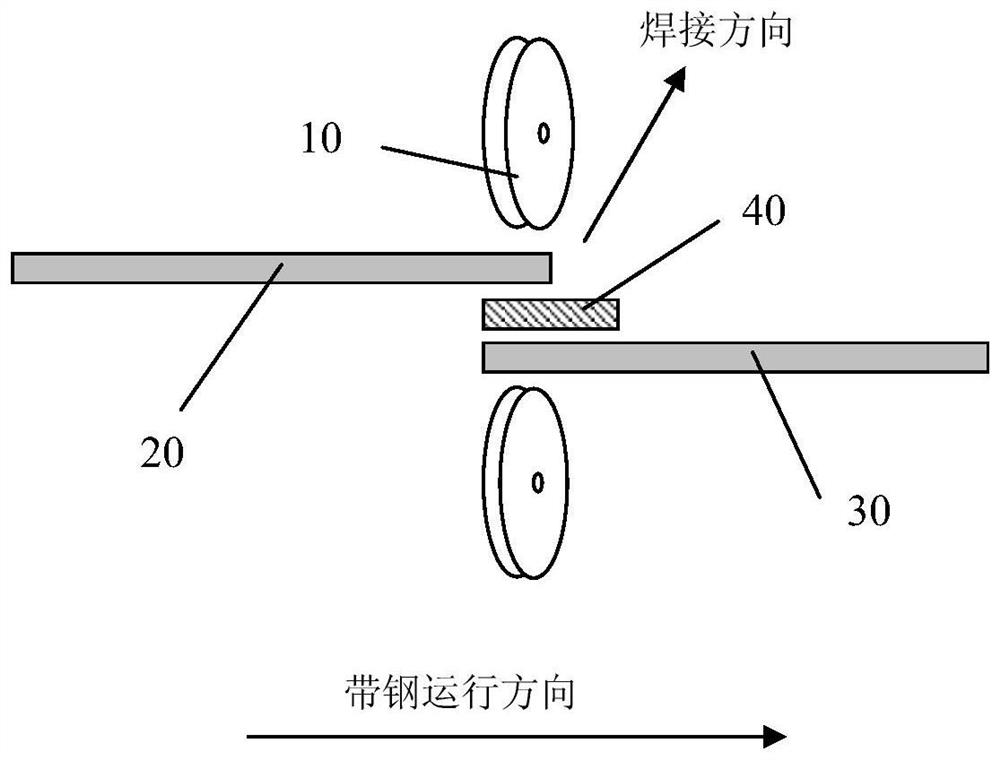

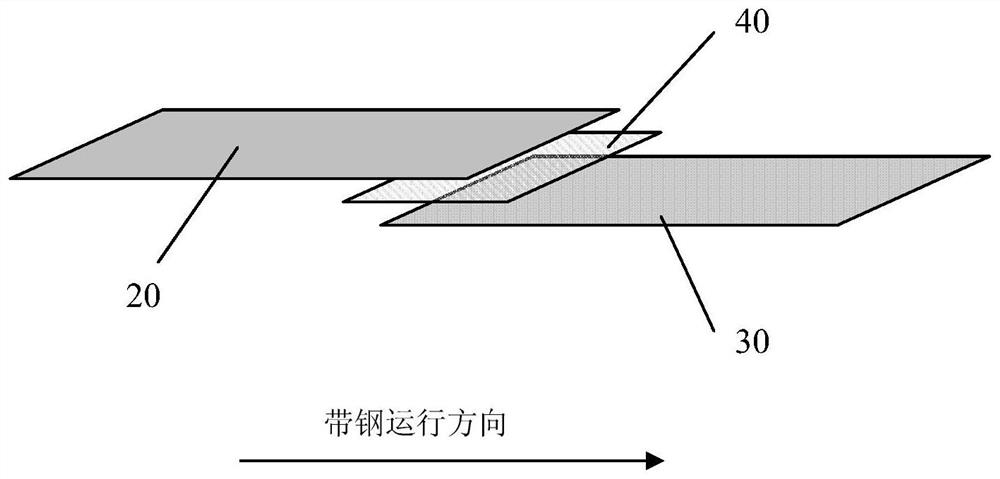

Method used

Image

Examples

Embodiment 1~3

[0041] 1) The front and rear strips are cut off the bad part of the plate and stay at the outlet and inlet clamps of the welding machine respectively, and the flatness of the steel plate is less than 2%;

[0042] 2) The front and rear strips are centered, and the centerline offset of the steel plate is less than 3mm;

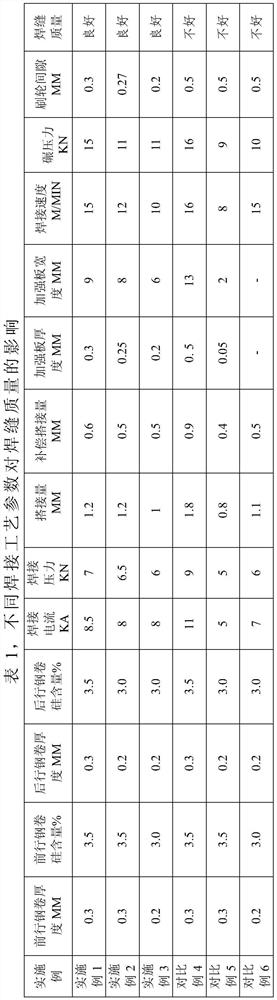

[0043] 3), the narrow lap rolling seam welding welding process is welded according to the parameters in Table 1;

[0044] 4) Select compressed air to protect and cool the weld during the welding process.

[0045] The relevant data parameters of Examples 1-3 and Comparative Examples 1-3 are given in Table 1.

[0046]The technology involved in the invention can remarkably improve the welding quality of the narrow lap rolling seam welding of high silicon thin gauge oriented silicon steel. The welding seams of the front and rear strip steels are well fused and have no warped edges; there is no perforation or cracking on the surface of the welding seam, and the wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com