Tunnel type multi-stage heat pump series drying and dehumidifying system

A drying and dehumidification, tunnel-type technology, applied in the field of tunnel-type multi-stage series heat pump drying and dehumidification systems, can solve the problems of large temperature difference between supply and return air, frosting of evaporators, and low heat pump performance, so as to increase the supply air temperature and improve drying. Efficiency, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

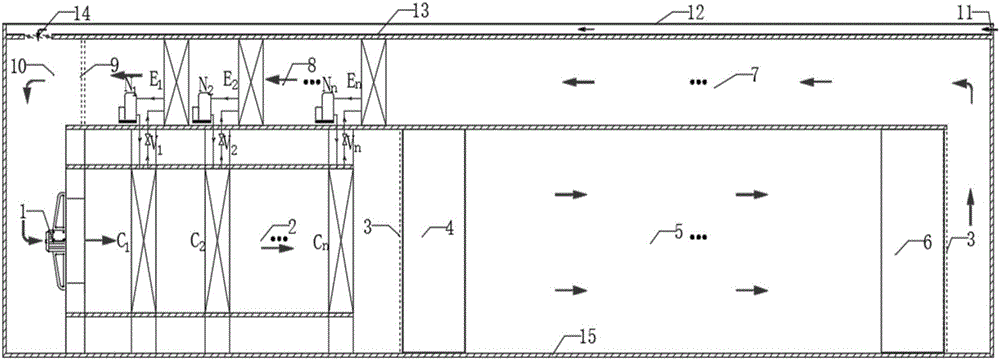

[0041] Embodiment 1 A tunnel-type multi-stage heat pump series drying and dehumidification system

[0042] A tunnel-type multi-stage heat pump series drying and dehumidification system, such as figure 1 As shown, it includes: multi-stage heating chamber 2, multi-stage dehumidification chamber 8, tunnel drying chamber 5, return air duct 7 and mixing chamber 10;

[0043] The entrance of the multi-stage heating chamber 2 is provided with a main blower 1, and communicates with the mixing chamber 10; The perforated plate 3 is respectively arranged at the rear part, and the front door 4 of the tunnel drying chamber and the back door 6 of the tunnel drying chamber are provided; the outlet of the tunnel drying chamber 5 is connected with the inlet of the multi-stage dehumidification chamber 8 through the return air duct 7; The outlet of the multi-stage dehumidification chamber 8 communicates with the mixing chamber 10, and a water baffle 9 is arranged between them. The multi-stage h...

Embodiment 2

[0046] Example 2 Method for drying materials in a tunnel-type multi-stage heat pump series drying and dehumidification system

[0047]Under the action of the main fan 1, the gas is heated and heated step by step from the first-stage condenser C1 to the n-stage condenser Cn, and the step-by-step heated gas enters the tunnel-type drying chamber 5 and is heated with fresh materials. Humidity transfer, the high-temperature and high-humidity gas passes through the return air duct 7 to carry out step-by-step cooling and dehumidification from the nth-stage evaporator En to the first-stage evaporator E1, and the air after step-by-step cooling and dehumidification enters the mixing chamber (10), Through the main fan 1, it enters again from the first-stage condenser C1 to the n-th-stage condenser Cn to complete the cycle;

[0048] Wherein, the fresh material is loaded on the side of the back door 6 of the tunnel drying chamber, and the material gradually moves along the opposite air sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com