Smoke cooling device

A flue gas cooling device and flue gas technology, applied in the steam generation method using heat carrier, heat exchange equipment, fixed tubular conduit assembly, etc., can solve low operating efficiency, cracking of tube plate welds, and low heat exchange efficiency and other problems, to achieve the effect of prolonging the service life, improving the heat transfer coefficient and enhancing the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

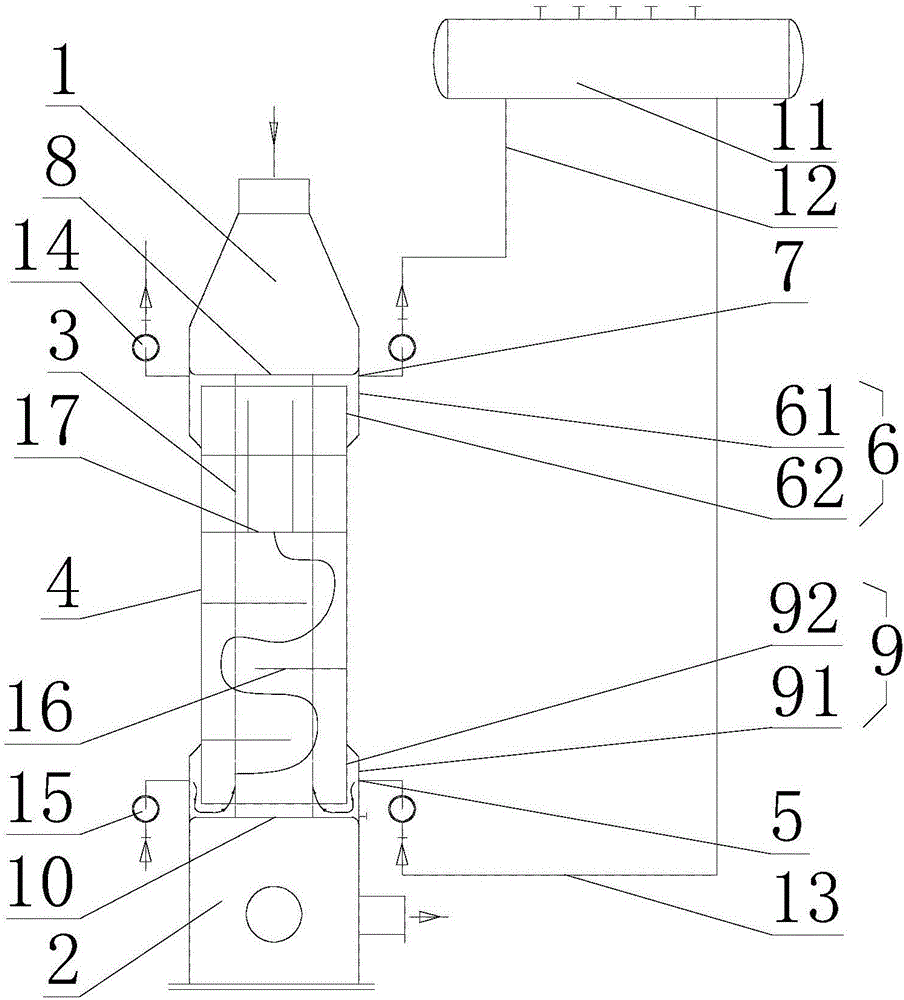

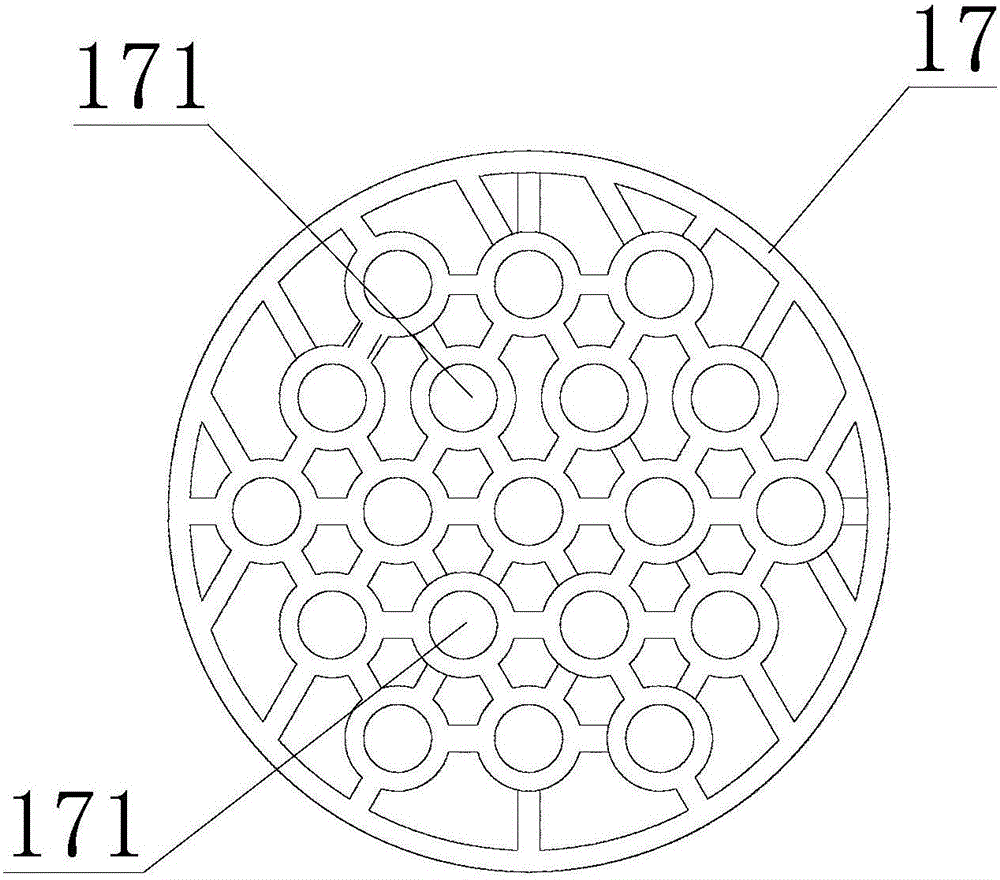

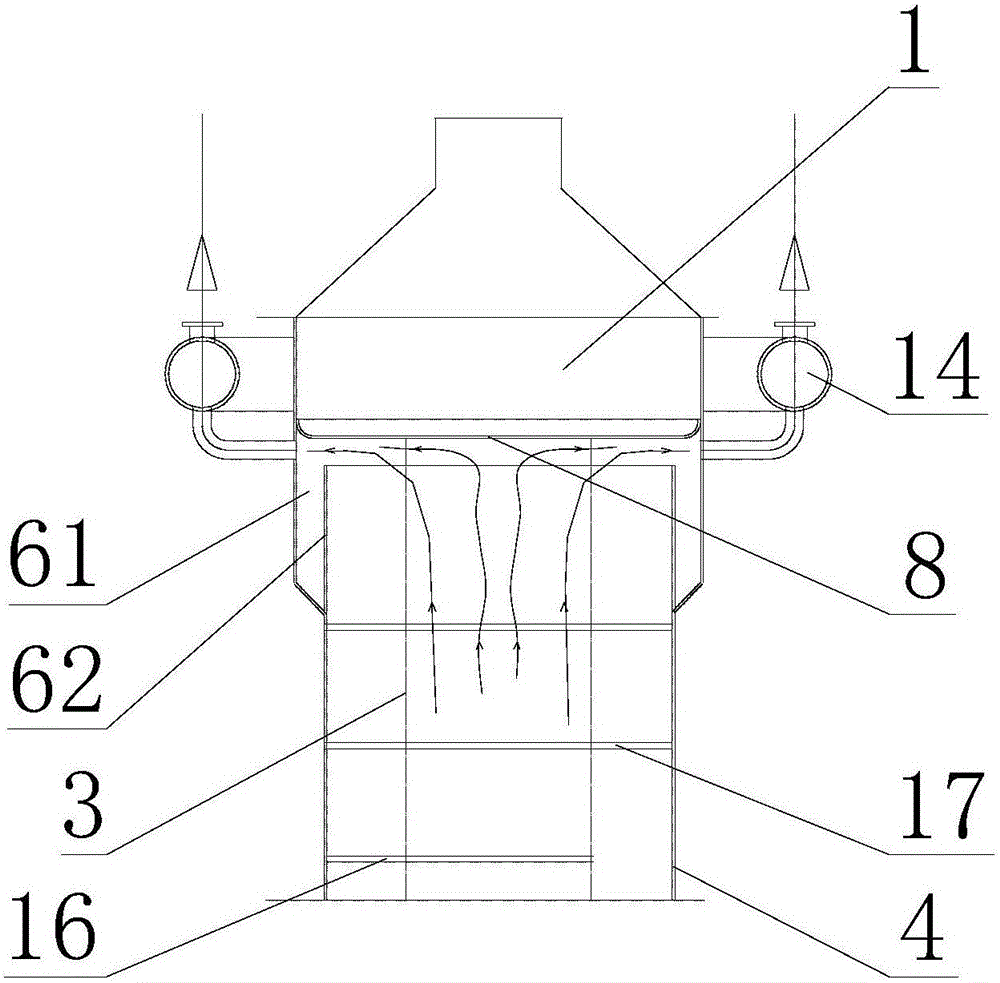

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] see Figure 1-4 As shown, the above-mentioned flue gas cooling device is used for heat exchange and cooling of high-temperature flue gas.

[0042] The flue gas cooling device includes an upper pipe box 1 for passing high-temperature flue gas, a lower pipe box 2 for passing out cooled flue gas, The heat exchange tubes 3 that enter and exit the flue gas; the heat exchange tubes 3 are distributed along the vertical direction.

[0043] The flue gas cooling device also includes a heat exchange mechanism for exchanging heat for the flue gas in the heat exchange tube 3, which is arranged between the upper tube box 1 and the lower tube box 2; The cylinder body 4 through which the water and the heat-exchanged water vapor pass out is also distributed along the vertical direction, and the heat exchange tube 3 is penetrated in the cylinder body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com