Efficient and energy-saving sterile heat pipe energy recovery device

An energy recovery device and energy-saving technology, applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of inability to deal with welding points and dead angles, large consumption of chilled water, and large energy consumption, and achieve easy cleaning and Disassembly and assembly, good energy saving effect, and the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

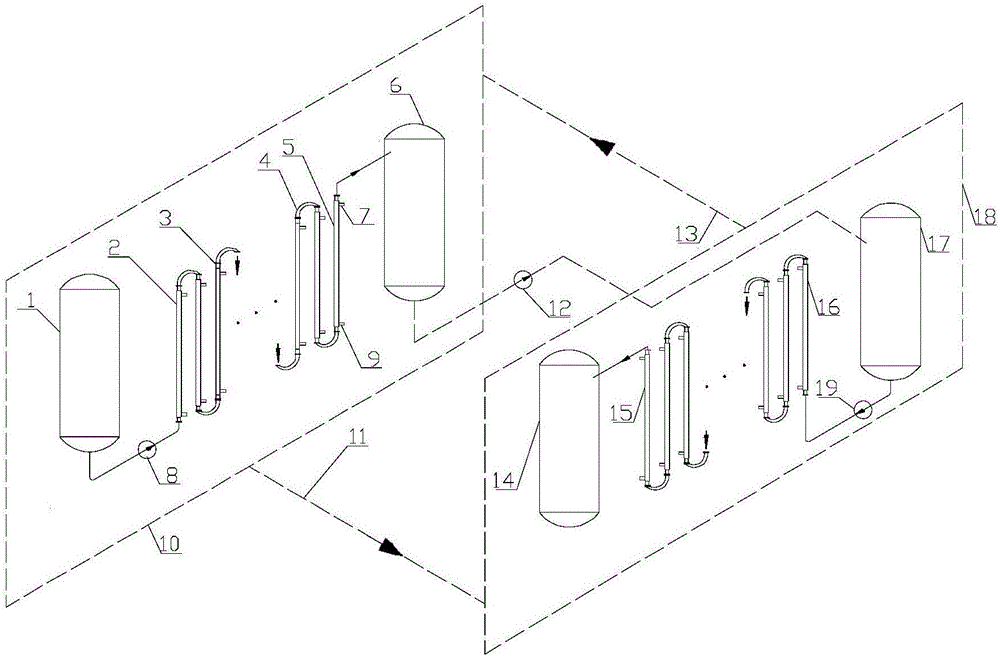

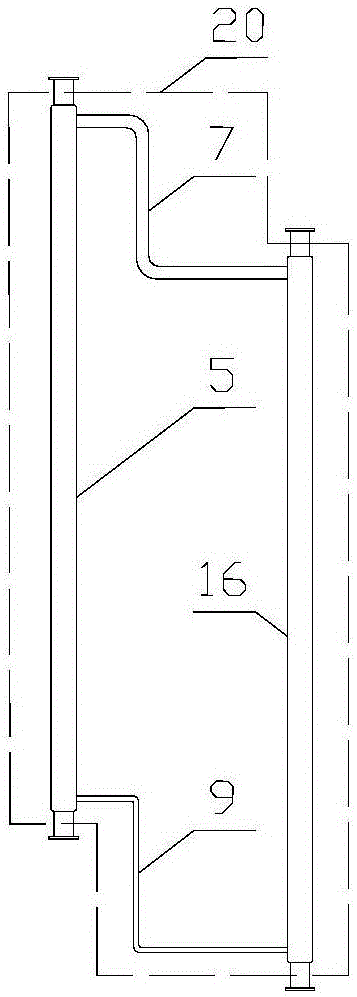

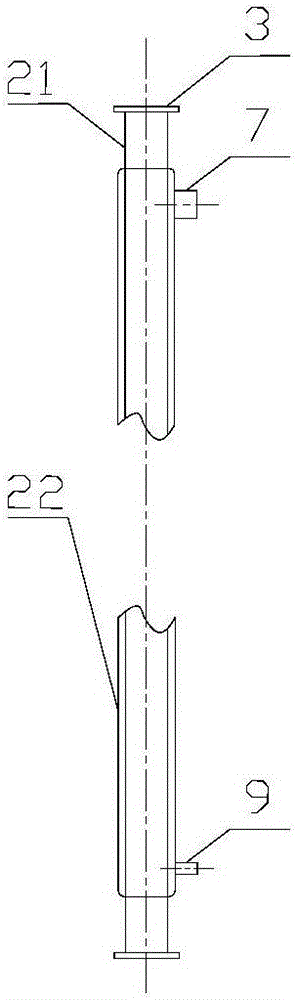

Embodiment 1

[0023] The high-efficiency and energy-saving aseptic heat pipe energy recovery device involved in this embodiment, the raw material container 1, the condensation section 2 of the last heat pipe subsystem, the clamp 3, the 180-degree elbow 4, and the condensation section 5 of the first heat pipe subsystem , heating tank 6, gas delivery pipe 7 of the heat pipe subsystem, cold solution pump 8, liquid return pipe of the heat pipe subsystem 9, cold solution flow subsystem before sterilization 10, liquid return pipe bundle 11 of the heat pipe subsystem, and transport pump 12. Air pipe bundle 13 of the heat pipe subsystem, cooling tank 14, evaporation section 15 of the last heat pipe system, evaporation section 16 of the first heat pipe system, standby heating tank 17, thermal solution pump 19, casing heat exchange The inner tube 21 of the device and the outer tube 22 of the sleeve heat exchanger are connected as a whole, and the number of condensing sections is 2 to 500, and the numb...

Embodiment 2

[0032] The main structure of the high-efficiency energy-saving aseptic heat pipe energy recovery device involved in this embodiment is the same as that described in Embodiment 1. When in use, the temperature of the hot solution in the standby heating tank 17 is controlled at 110°C, and the temperature of the cold solution in the raw material container 1 After passing through the energy recovery device of the present invention, the temperature of the hot solution is reduced from 110°C to 50°C, and the temperature of the cold solution is increased from 20°C to 80°C; on this basis, only Just heat 80°C to 110°C, which saves (80-20) / (110-20)=66.66% of the heating capacity, and at the same time in the cooling tank, only cools 50°C to 25°C, which saves (110-50) / (110-25)=70.59% cooling capacity; it can be seen that the energy-saving effect after the implementation of this embodiment is very significant, which can greatly reduce the operating cost of the production process, save costs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com