Hydraulic machinery blade surface detecting method and device

A technology of hydraulic machinery and detection methods, which is applied to mechanical measurement devices, mechanical devices, measurement devices, etc., can solve the problems of slow measurement speed, slow speed, and difficulty in obtaining comprehensive surface information, so as to achieve convenient equipment installation and accurate detection. High accuracy and fast inspection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

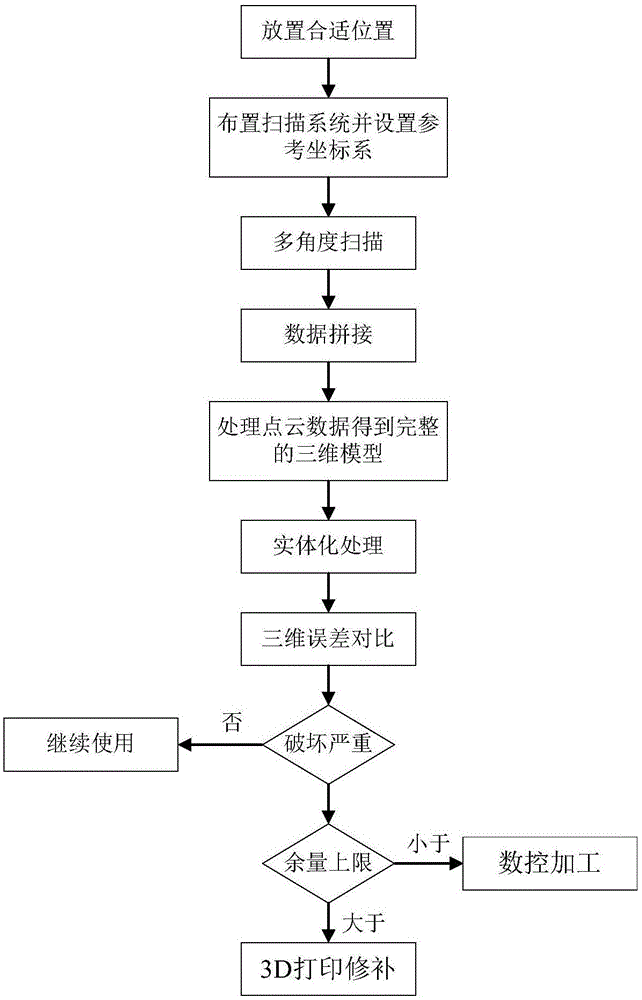

[0028] figure 1 The specific process of 3D scanning is given, which is mainly divided into experiment preparation, image acquisition and post-processing stages.

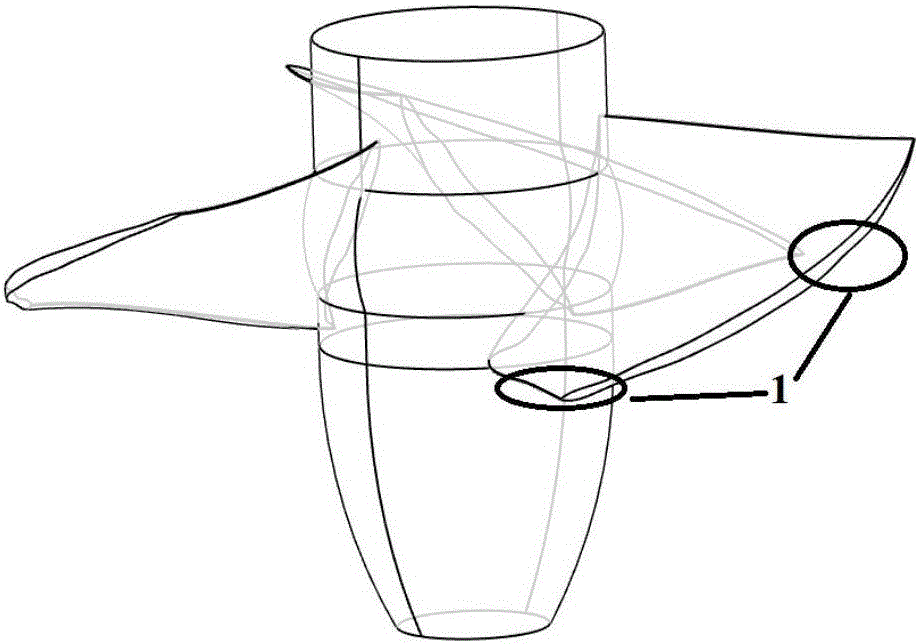

[0029] Such as figure 2 As shown, it is enough to place the impeller to be tested in a suitable position to ensure sufficient light, and there is no need to disassemble it from the original hydraulic machine and disassemble it (unless the shooting angle is blocked due to the structure of the hydraulic machine).

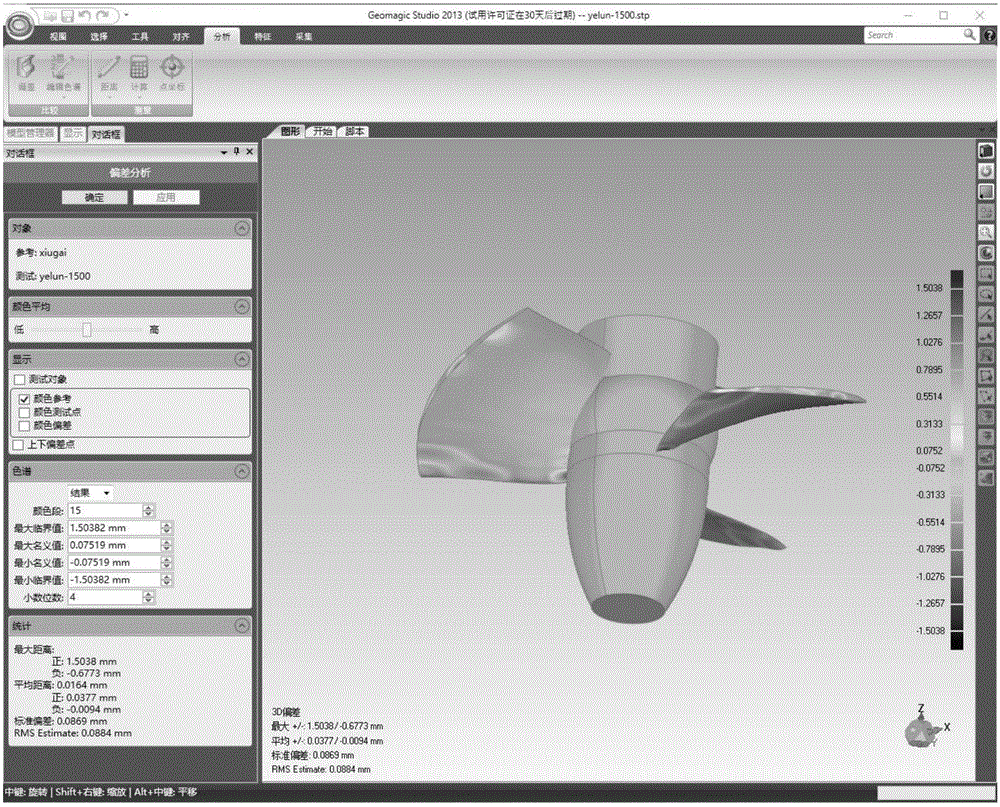

[0030] combine image 3 , arrange the specific positions of each component, fix two high-speed cameras and a grating projection device on the bracket, arrange the two cameras at an angle of 60°, and place the grating projection device in the middle of the two cameras, and face the impeller to be tested , adjust the shooting angle to a suitable position to focus and set a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com