Low-cost rapid measurement method for ultrasonic transducer signal and circuit

A signal measurement and transducer technology, applied in measurement devices, measurement of flow/mass flow, liquid/fluid solid measurement, etc., can solve the problems of expensive, inaccurate consistent results, and achieve low power consumption, stable measurement, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate the present invention below in conjunction with accompanying drawing.

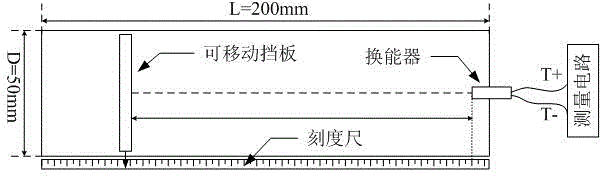

[0015] refer to figure 1 , Install the transducer coaxially in a closed pipeline with a length of 200mm and a diameter of 50mm, and the inside is air at normal temperature and pressure. The baffle in the pipe can move axially to adjust the length of the sound wave reflection path. The two pins T+ and T- of the ultrasonic sensor to be tested are connected to the circuit.

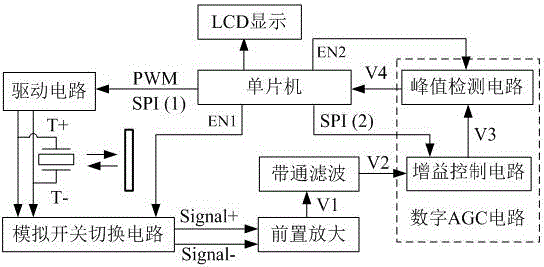

[0016] refer to figure 2 , the working process of the whole system is: the SPI (1) communication interface of the single-chip microcomputer adjusts the digital potentiometer, changes the driving voltage, and generates a PWM control driving circuit at the same time, so that the transducer obtains the excitation voltage T+ and T-. The microcontroller controls the timing of the analog switch switching circuit through the EN1 port, so that the transducer enters the receiving state after being excited. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com