Automatic water-quality layering and sampling system

An automatic layering and sampling system technology, applied in sampling, analyzing materials, sampling devices, etc., can solve problems such as high difficulty in research and development, difficulty in achieving full coverage in time domain, large manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

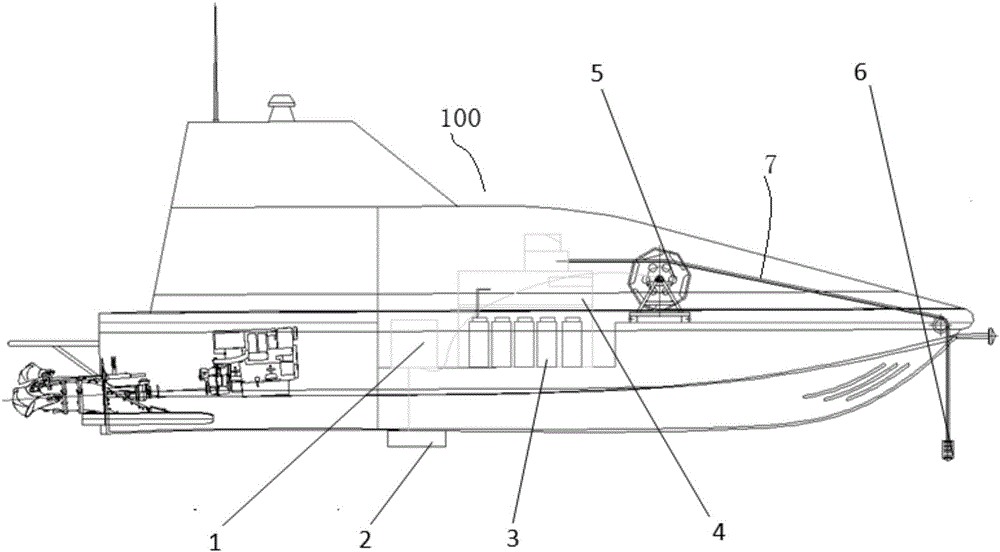

[0011] Such as figure 1 As shown, a water quality automatic layered sampling system, including:

[0012] An unmanned boat 100 with autonomous navigation function, and a sampling module installed on the unmanned boat, the sampling module includes a peristaltic pump (not shown), a sampling water distributor 4, a servo roll tube 5, a single beam sounding Sensor 2, water depth pressure sensor 6, multiple sampling bottles 3, water suction pipe (not shown) and PLC control system 1; The peristaltic pump is connected to the sampling water distributor through the water suction pipe, and the sampling water distributor is connected to multiple described Sampling bottle; the water depth pressure sensor is installed on one end of the coiled tube winding line 7 on the servo coiled tube and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com