Preparation device and preparation method of blind joint-containing rock-like sample

A rock sample and preparation device technology, which is applied in the fields of civil engineering and hydropower engineering, can solve problems such as the inability to prepare samples with hidden joints, and achieve the effects of high conformity, avoidance of damage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

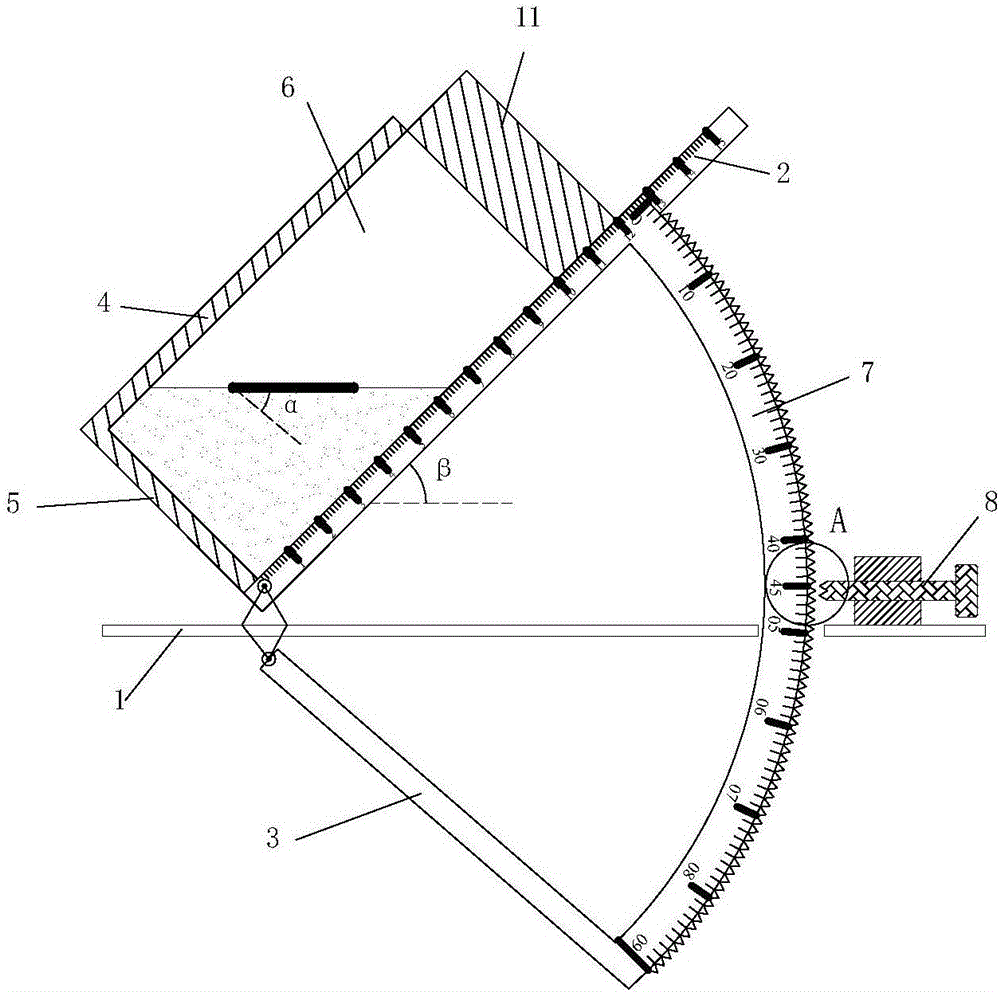

[0034] Preparation of sandstone-like samples with hidden joint dip angle α1=45°, connectivity rate k1=22.4%, number n1=2, distance D1=2cm includes the following steps:

[0035] 1) Using 3D printing technology, two detachable semi-cylindrical molds are made of resin materials, and then the two semi-cylindrical molds are fixed together with two metal strips with bolts to form a standard cylindrical mold with a size of Φ50 ×100;

[0036]2) A thin tin sheet is used to simulate hidden joint fissures. The thickness of the tin sheet is 0.1mm. The tin sheet is cut into an ellipse with a long axis a=2cm and a short axis b=1cm, so that the connection rate of the formed joint k1=22.4% ;

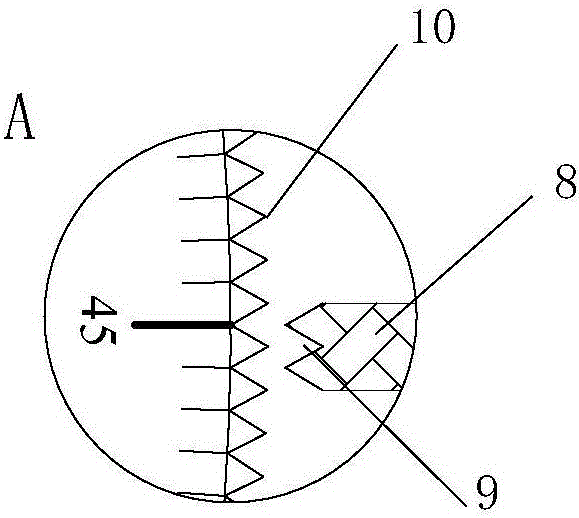

[0037] 3) Adjust the hidden joint sample preparation device so that the scale β=45° on the arc-shaped support frame 7 corresponding to the position of the bottom plate 1 is fixed, then the hidden joint inclination angle is α=90°-45°=45°, and then The standard mold prepared by step 1) is put into the c...

Embodiment 2

[0044] Preparation of sandstone-like samples with hidden joint dip angle α2=60°, connectivity rate k2=67.2%, number n2=3, distance D2=1cm includes the following steps:

[0045] 1) After demolding the sample in Example 1, the mold can be reused after cleaning. Same as embodiment 1, two semi-cylindrical molds are fixed together with two metal strips with bolts to form a standard cylindrical mold.

[0046] 2) A thin tin sheet is used to simulate hidden joint fissures. The thickness of the tin sheet is 0.1mm. In this example, the joint connectivity rate k2=67.2%, so the tin sheet is cut into an ellipse with a long axis a=3cm and a short axis b=2cm ;

[0047] 3) Adjust the hidden joint sample preparation device so that the scale β on the arc-shaped support frame 7 corresponding to the position of the bottom plate 1 is fixed at 30°, then the hidden joint inclination angle is α=90°-30°=60°, and then Put the standard mold prepared in step 1) into the sample holder;

[0048] 4) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com