Centrifugal anthracite viscosity testing equipment

A test equipment, anthracite technology, applied in the direction of removing a certain component and weighing, etc., can solve the problems of low experimental efficiency and complex equipment structure, and achieve the effect of simple and compact structure, improving measurement efficiency and shortening measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

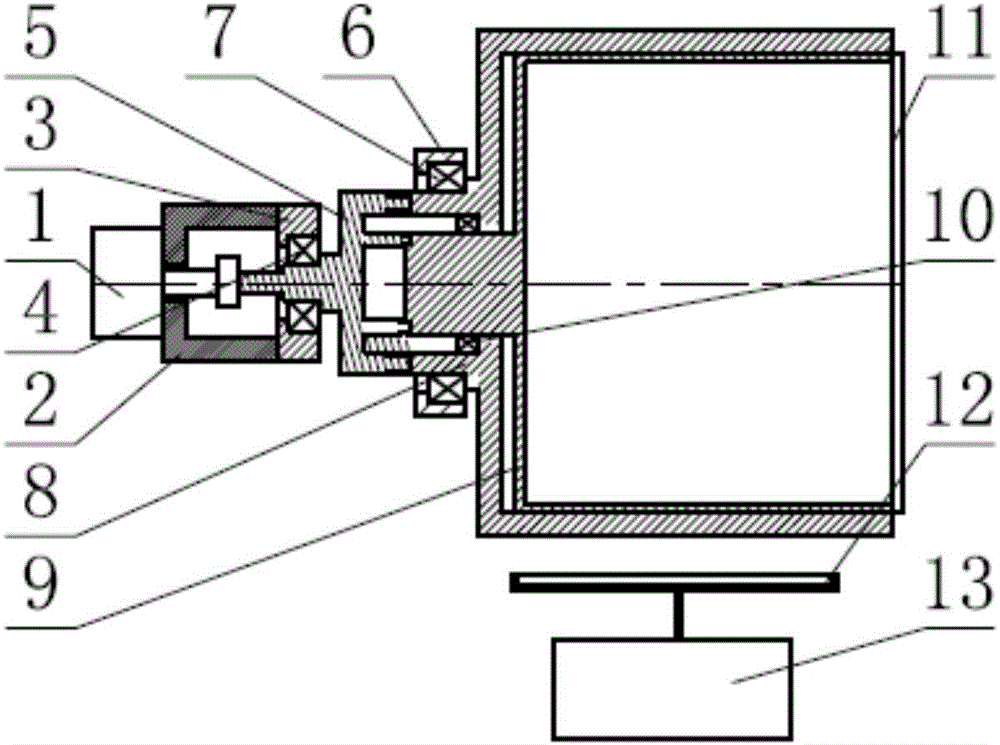

[0014] see figure 1 As shown, a kind of centrifugal type anthracite viscosity testing equipment of the present invention, it comprises analytical balance 13, weighing pan 12, motor 1, motor frame 2, clutch frame 3, bearing A4, clutch 5, bearing B frame 6, bearing B7 , Composite drum, bearing C10 and end cover 11; weighing pan 12 is installed on the analytical balance 13, and is located directly below the composite drum.

[0015] see figure 1 As shown, the motor 1 is installed on the motor frame 2, and its output shaft is connected to the left end of the clutch 5; the clutch 5 passes through the bearing A4 installed on the clutch frame 3; the end cover 11 is installed on the right end of the composite drum; The composite drum includes a composite drum outer layer 8 and a composite drum inner layer 9; the bearing C10 is installed insi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com