Geologic body structural surface stress-fluid coupling shearing rheological system

A structural surface and seepage technology, applied in the direction of applying a stable shear force to test material strength, permeability/surface area analysis, and measurement devices, can solve problems such as inability to perform rheological conditions, and increase the maximum shear load Strength, good sealing effect, and the effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

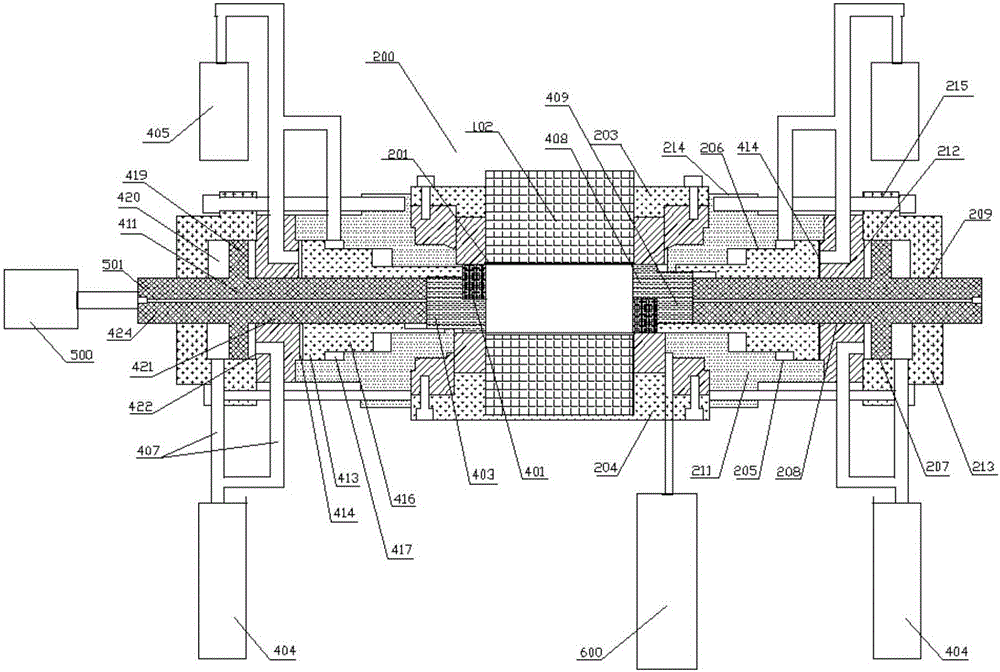

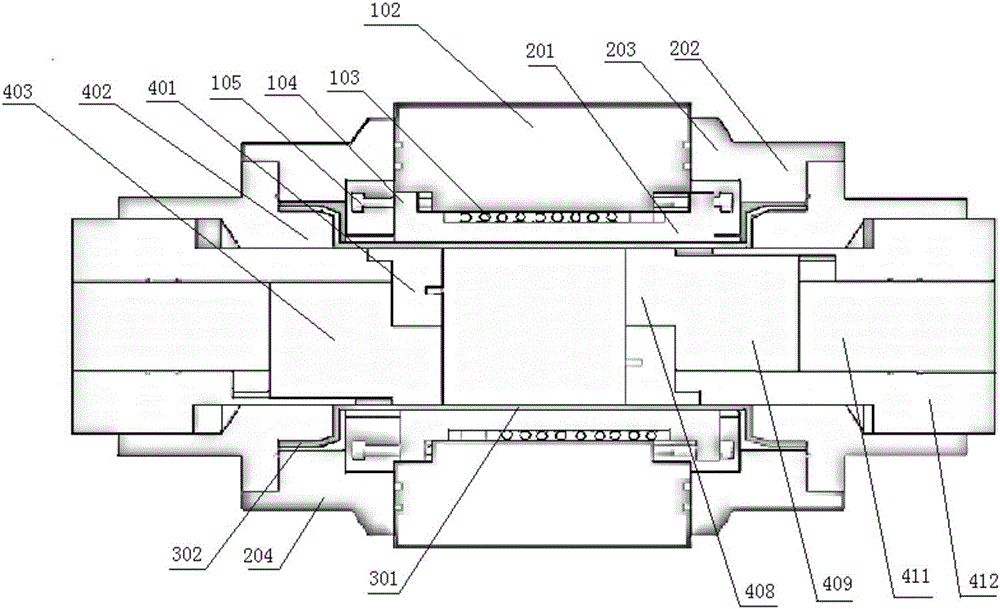

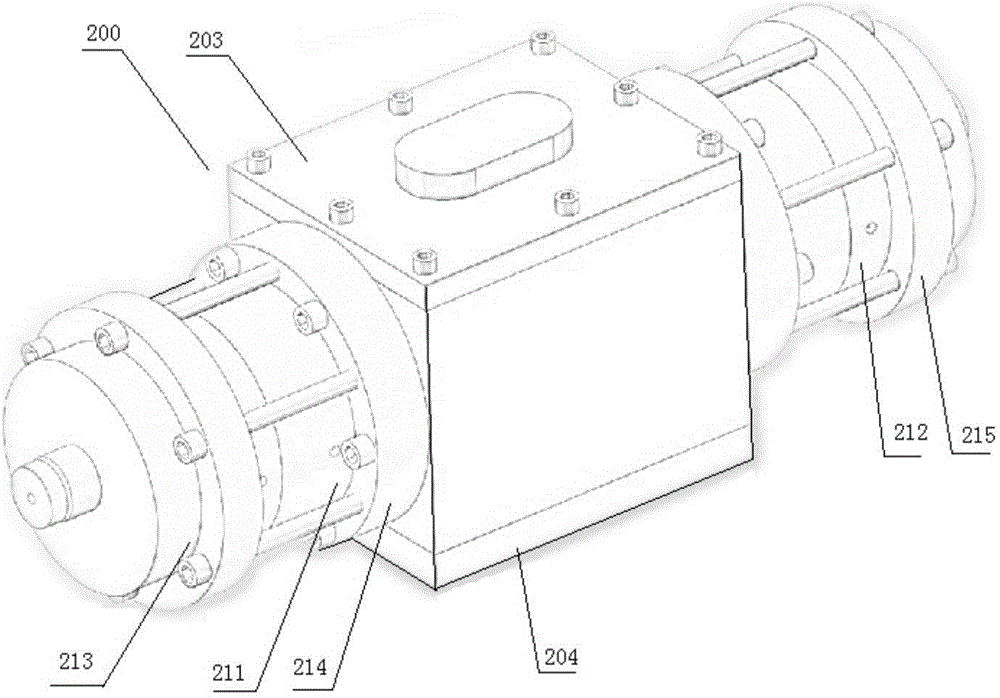

[0083] A stress-seepage coupled shear rheological system on a structural surface of a geological body, comprising: a normal loading system for applying a normal load to a rock specimen; a shear box 200, which includes a box internally configured to accommodate Body accommodating portion 201, the two sides of box body accommodating portion 201 are box body connecting portion 202, the inner wall size of box body connecting portion 202 is larger than the inner wall size of box body accommodating portion 201; The rubber sleeve receiving part 301 on the outer surface of the test piece, the rubber sleeve connecting part 302 is on both sides of the rubber sleeve receiving part 301, the outer peripheral size of the rubber sleeve connecting part 302 matches the inner wall size of the box body connecting part 202; the shear loading system , including two mutually staggered active loading ends 401 arranged in the shear box 200 to apply shear force to both sides of the rock sample, the act...

specific Embodiment approach

[0128] The normal servo loading system and shear servo control system adopt EDC full digital servo controller imported from German DOLI company, which can control force, displacement and deformation. The servo loading system is mainly used to realize the shear rheological test of rock joints under the condition of stress and seepage coupling, including normal loading and shear loading. Different servo control methods for vertical stress (CNL) and constant normal displacement (CNV). The main technical indicators of the normal loading part are: the maximum normal test force 1000kN; the test force measurement accuracy (within the range of 5% to 100% of the full scale) ≤ ± 1% of the indicated value; the normal actuator travel range 0 -100mm; actuator displacement measurement accuracy is <±1% of indication value; axial test force loading rate is 0.01~100kN / s, accuracy ≤±1% of indication value; deformation measurement in normal direction is 25mm four displacement sensors , measurem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com