Crystal laser pretreatment and point-to-point damage testing device and testing method

A technology of laser preprocessing and testing equipment, which is applied in the direction of measuring equipment, optical testing of flaws/defects, and material analysis through optical means. and other problems to achieve the effect of finding points with high precision and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

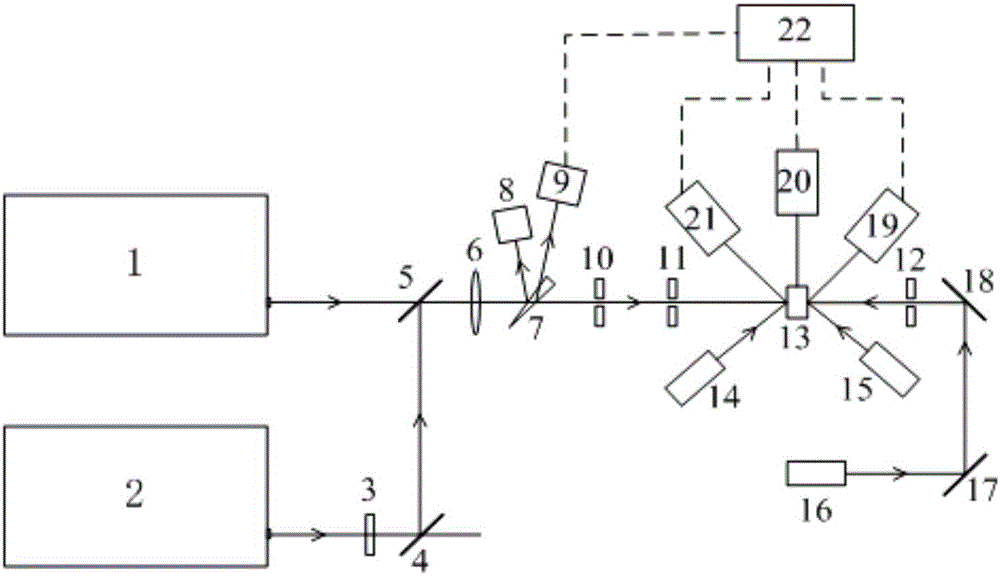

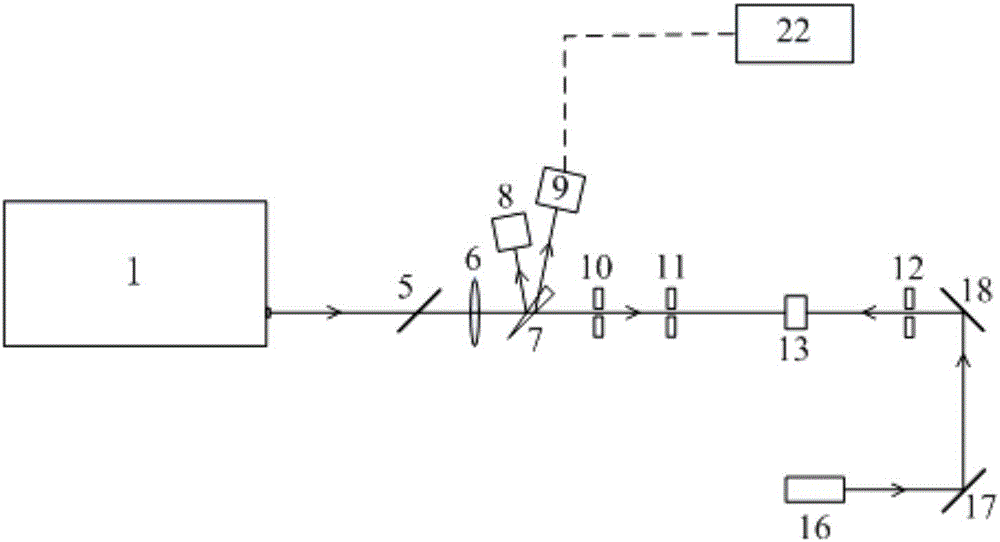

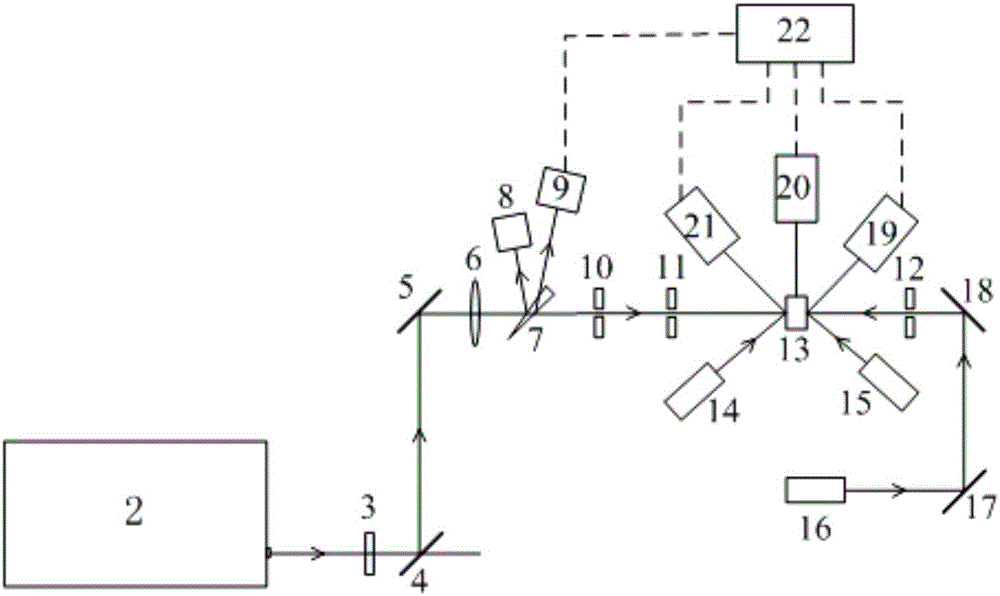

[0046] A crystal laser pretreatment and point-to-point damage testing device, including a sub-nanosecond laser and a nanosecond laser arranged side by side;

[0047] One end of the nanosecond laser is provided with a half-wave plate and a first plane reflector; the half-wave plate is used to change the horizontally polarized light emitted by the nanosecond laser into vertically polarized light;

[0048] One end of the sub-nanosecond laser is provided with a polarizer, a focusing lens, a wedge plate, a small hole diaphragm, a sample crystal to be tested, and a small hole diaphragm, and one side of the wedge plate is equipped with an energy meter, a spot analyzer, a spot analyzer and a computer. The two sides of the sample crystal to be tested are respectively equipped with a He-Ne laser and a CCD camera, and the CCD camera is connected to the computer. The polarizer completely reflects the vertically polarized laser pulse and completely transmits the horizontally polarized laser...

Embodiment 2

[0053] A crystal laser pretreatment and point-to-point damage testing device, the structure of which is as described in Embodiment 1, the difference is that the number of small hole apertures between the wedge plate and the sample crystal to be tested is two. The laser light path of the sub-nanosecond laser pretreatment is determined by two aperture apertures. The relative positional relationship between the aperture aperture and the sample crystal to be tested is fixed. In the subsequent point-to-point damage test, the nanosecond laser is adjusted so that it also It can just pass through these two small apertures, and the strict collinearity of the sub-nanosecond laser pulse and the nanosecond laser pulse ensures that the pretreatment point of the sub-nanosecond laser pulse on the sample crystal to be tested is the point-to-point of the nanosecond laser pulse Online Damage Threshold Test Point.

Embodiment 3

[0055] A crystal laser pretreatment and point-to-point damage testing device, its structure is as described in Embodiment 1, the difference is that three CCD cameras are provided on one side of the sample crystal to be tested, and three He-Ne lasers are provided on the other side of the sample crystal to be tested . Three He-Ne lasers and three CCD cameras are used to observe the damage of the front surface, body and back surface of the sample crystal to be tested, and the observation is more three-dimensional and comprehensive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com