Visual inspection system and method for glued products

A visual inspection and product technology, applied in the field of visual inspection systems for glued products, can solve problems such as injury, subjective missed judgment efficiency, low UV light source human health, etc., to achieve stable acquisition, improve detection accuracy, and prevent missed judgments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

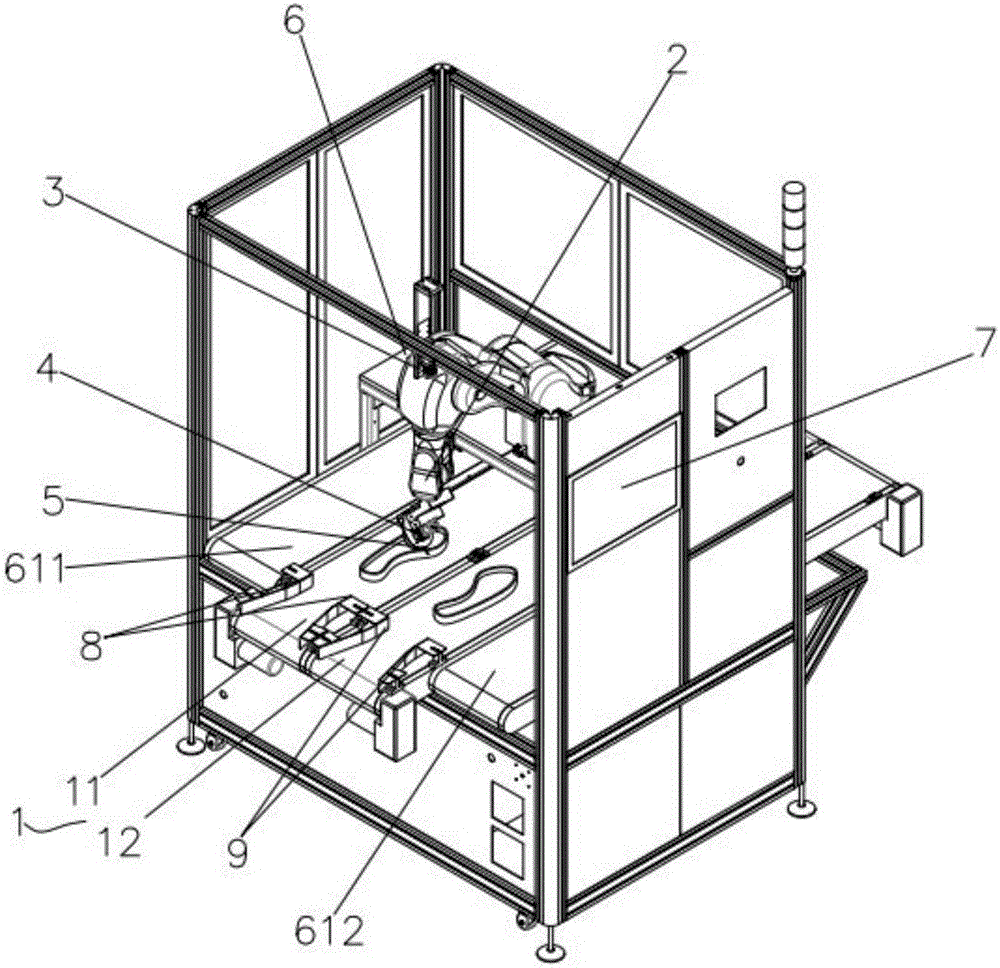

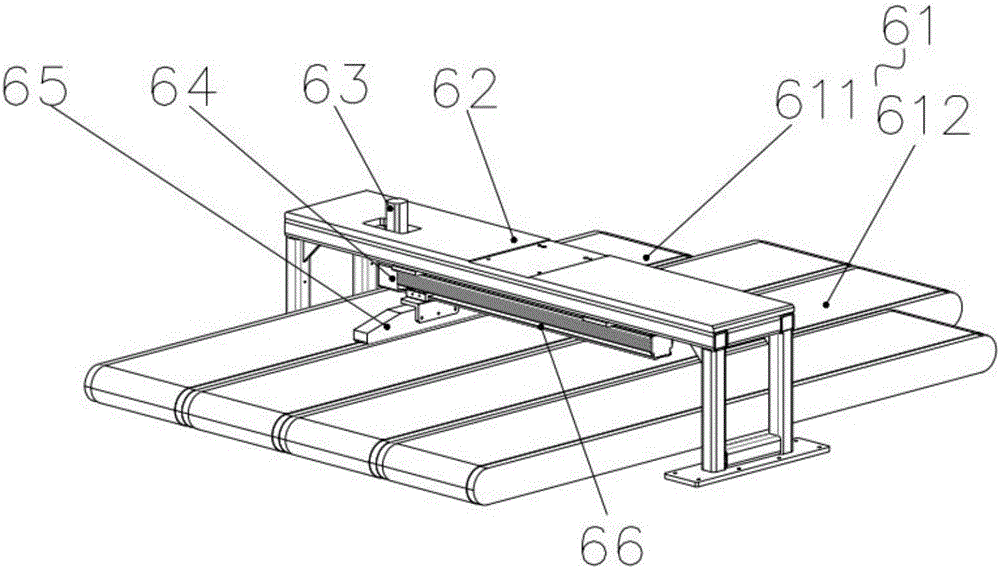

[0026] like figure 1 , figure 2 As shown, a visual inspection system for glued products includes a conveyor belt 1, a sensor, a PLC, a camera, a light source, an industrial robot 2, a rejecting device 6 and an industrial computer 7, and the industrial computer 7 is arranged on a frame, and the camera, The light source and industrial robot 2 are all connected to the industrial computer 7, and the imaging device and the light source are controlled by the industrial computer. The imaging device includes a top camera 3 and a detection camera 4, and the light source includes a detection light source 5 and a backlight (not shown), wherein, The detection light source 5 is a UV light source, the backlight is arranged at the bottom of the conveyor belt 1 and illuminates the conveyor belt to form a backlight irradiation area, the detection camera 4 and the detection light source 5 are arranged on the industrial robot 2 above the conveyor belt 1 towards the backlight area, Products coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com