Detecting system in curing process of preparing anisotropic conductive composite material

A conductive composite material and process detection technology, which is applied in the detection field, can solve the problems that the electrical impedance tomography technology does not have high-performance and precise conductive composite materials, so as to save curing time and raw material resources, accurate electrical characteristics, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

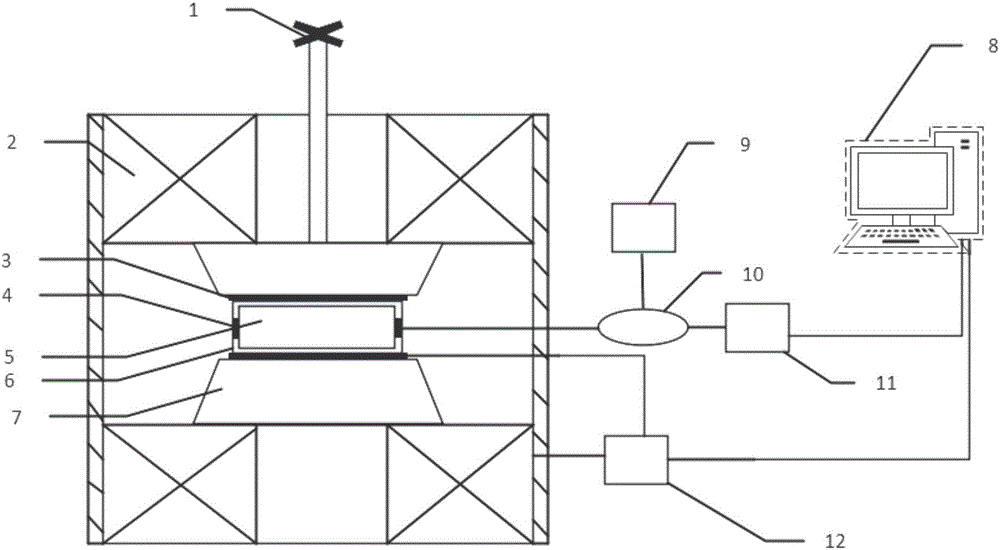

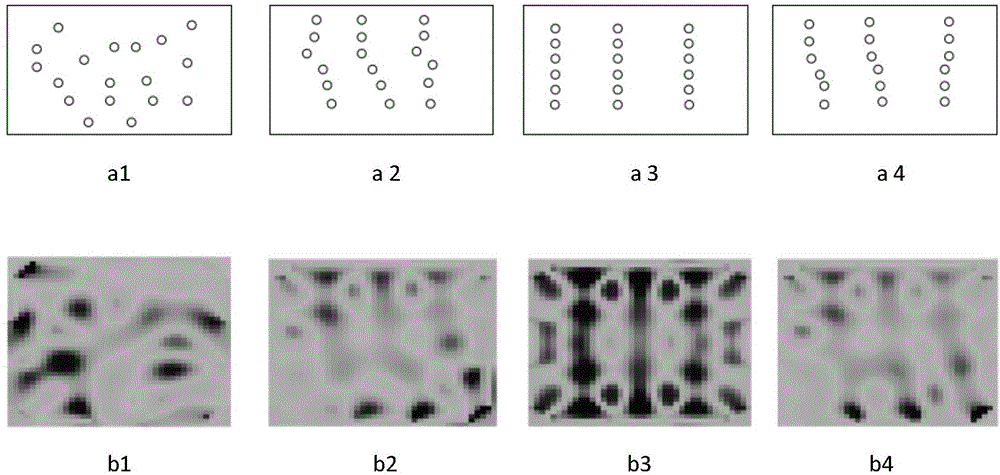

[0020] The structural form of the detection system for the curing process of preparing anisotropic conductive composite materials in this embodiment is: a composite material curing unit capable of heating the material mold and forming an external magnetic field for the heated material mold is provided; an electrode signal detection unit is provided. Each electrode 4 is distributed in an array on the inner sidewall of the material mold, and forms good contact with the material in the material mold; according to the electrode signal collected in real time, the conductivity change during the curing process of the conductive composite material 5 is analyzed by using electrical impedance imaging technology Carry out real-time image reconstruction, use the reconstructed image to obtain the distribution of conductive particles in the matrix, and adjust the strength of the external magnetic field in real time according to the distribution of conductive particles in the matrix, and adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com