Welding seam eddy current detection test block and manufacturing method thereof

A technology of eddy current testing and manufacturing methods, applied in the direction of material magnetic variables, etc., can solve problems such as inability to realize live detection, affect detection results, and unsuitable rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

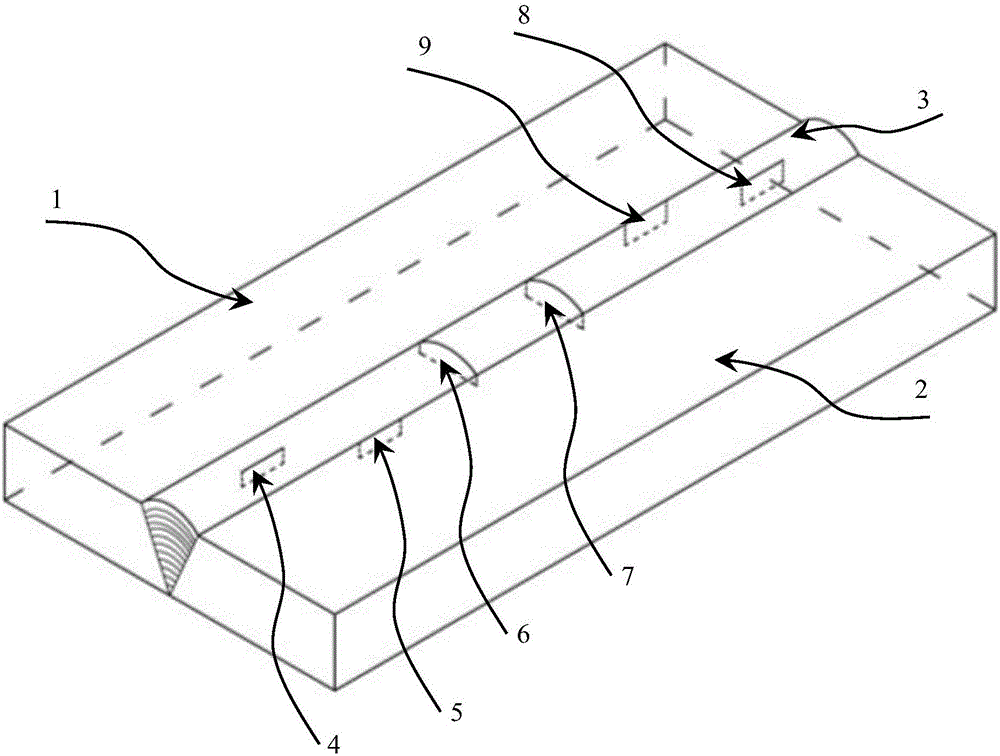

[0043] refer to figure 1 , a method for making a weld seam eddy current test block is as follows:

[0044] The first step: processing the groove on the corresponding side of the test block base 1 and the test block base 2; the second step: butt welding the grooves of the test block base 1 and the test block base 2 2; the third step: welding Brush the paint on the base of the good test block; the fourth step: use EDM to process 8 non-transparent artificial grooves.

[0045] The weld seam eddy current testing test block includes: test block base 1, test block base 2 2, weld 3 and several crack structures; test block base 1 and test block base 2 are butt welded, and weld 3 is located on the test block Between base one 1 and test block base two 2; weld reinforcement 2 mm; test block thickness 8 mm; the surface of the test block is a paint layer. The crack structure is a non-transparent artificial groove, including groove one 4, groove two 5, groove three 6, groove four 7, groove...

Embodiment 2

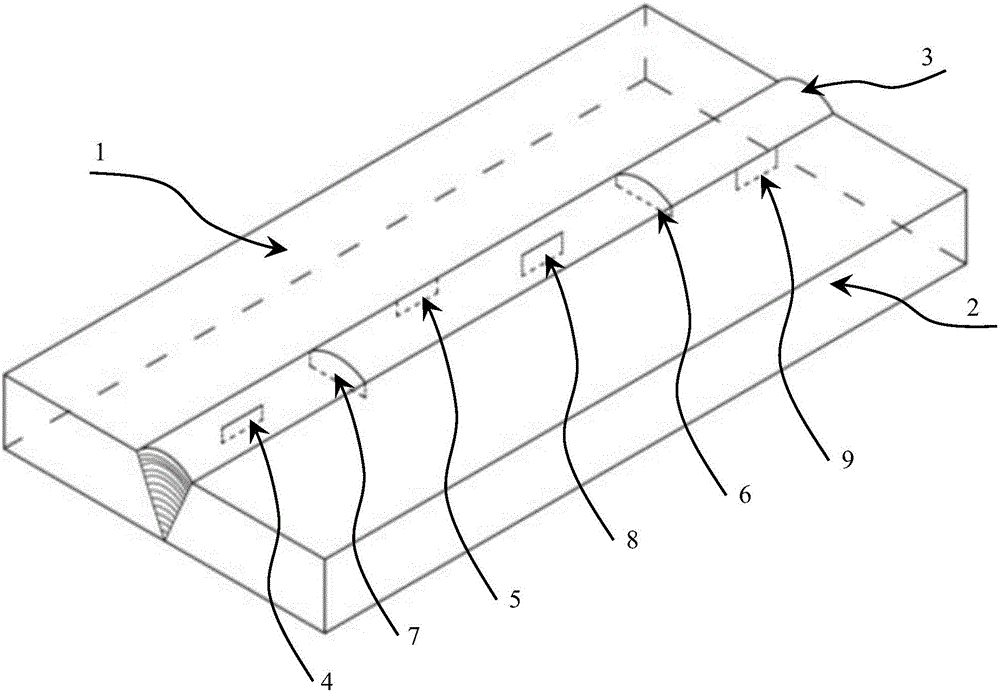

[0051] refer to figure 2 , a method for making a weld seam eddy current test block is as follows:

[0052] The first step: processing the groove on the corresponding side of the test block base 1 and the test block base 2; the second step: butt welding the grooves of the test block base 1 and the test block base 2 2; the third step: welding Brush the paint on the base of the good test block; the fourth step: use EDM to process 8 non-transparent artificial grooves.

[0053]The weld seam eddy current testing test block includes: test block base 1, test block base 2 2, weld 3 and several crack structures; test block base 1 and test block base 2 are butt welded, and weld 3 is located on the test block Between base one 1 and test block base two 2; weld reinforcement 2 mm; test block thickness 8 mm; the surface of the test block is a paint layer. The crack structure is a non-transparent artificial groove, including groove one 4, groove four 7, groove two 5, groove five 8, groove ...

Embodiment 3

[0059] Waveform diagram analysis of groove contrast sample defect detection

[0060] refer to image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , for the analysis of detection waveforms of 1mm deep defects in four different comparison test blocks, the defect wave sensitivity of the base metal is the highest, the waveform has no width, and the angle difference from the interference wave angle of the weld itself is the largest, which is about 20°; Due to the influence of weld waves in the longitudinal and transverse defects, the sensitivity is 2dB lower than that of the base metal defect, and the waveform has some width; when detecting defects in the heat-affected zone of the weld, in addition to selecting the probe parallel to the weld in the heat-affected zone In addition to the (longitudinal) scanning, the horizontal scanning of the probe and the weld should be added. Since the flat probe of about Φ15mm is selected, the defects near the edge of the weld will be m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com