Method for detecting content of guanidine phosphate in textile and filling material

A technology of filling materials and guanidine phosphate, which is applied in the field of analytical chemistry, can solve the problems of no method for detecting the content of flame retardant guanidine phosphate, and achieve the effect of fast and accurate determination of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

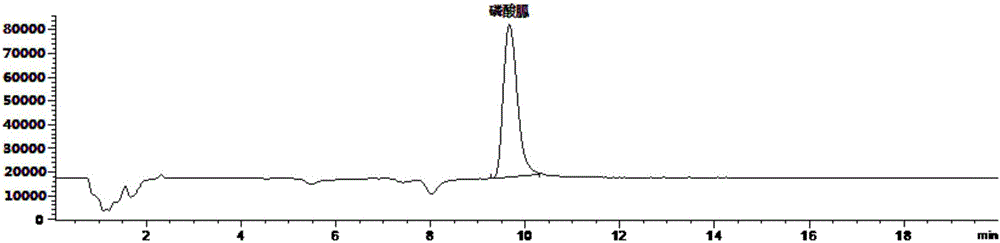

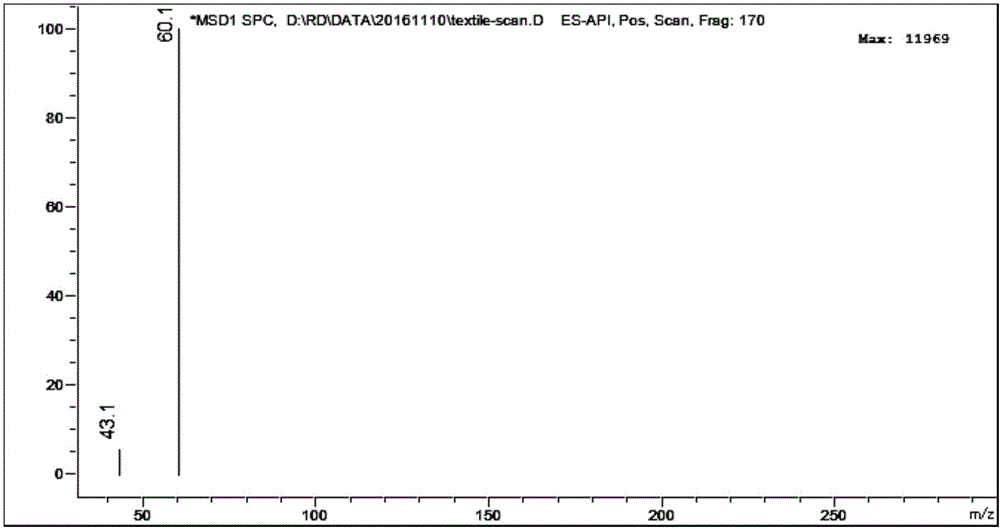

Image

Examples

Embodiment 1

[0034] Embodiment 1: the mensuration of guanidine phosphate content in the filling cotton

[0035] 1. Preparation of sample solution:

[0036] Crush the stuffing cotton with a pulverizer, the size of the sample shall not exceed 2mm×2mm×2mm, mix it evenly, put it into a clean and dry ziplock bag, and seal it for later use. Weigh 0.3g of the sample into a 40mL glass screw bottle, add 30mL of methanol-water (85︰15) solution, tighten the bottle cap and extract ultrasonically in a 60°C water bath for 60min, after cooling, take 20mL of the extract and pass through a 0.45μm PTFE organic phase Membrane filtration in a 50mL flat-bottomed flask. The solution in the flat-bottomed flask was rotary evaporated at 70°C to nearly dryness, and the residue was dissolved with methanol-water (85:15) solution and the volume was adjusted to 1 mL, mixed well, and analyzed by liquid chromatography-mass spectrometry.

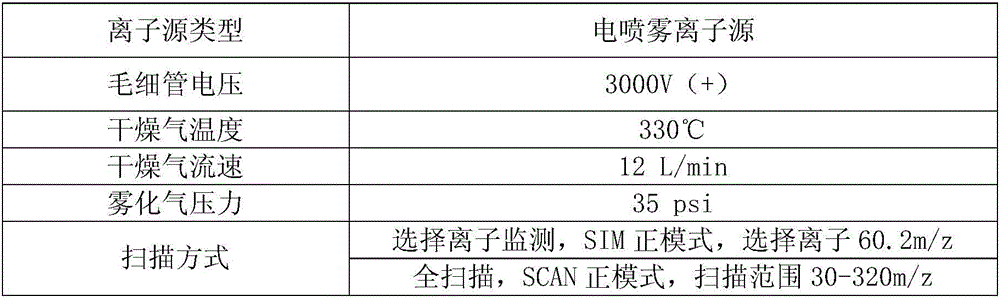

[0037] 2. Set the instrument parameters:

[0038] 1) The liquid chromatographic ...

Embodiment 2

[0053] Embodiment 2: the mensuration of guanidine phosphate in cotton cloth

[0054] 1. Sample preparation:

[0055] Cut the cotton cloth with scissors, the sample size shall not exceed 2mm×2mm×2mm, mix well, put it into a clean and dry ziplock bag, seal it for later use. Weigh 0.3g of the sample into a 40mL glass screw bottle, add 30mL of methanol-water (85︰15) solution, tighten the bottle cap and extract ultrasonically in a 60°C water bath for 60min, after cooling, take 20mL of the extract and pass through a 0.45μm PTFE organic phase Membrane filter in a 50mL flat bottom flask. The solution in the flat-bottomed flask was rotary evaporated at 70°C to nearly dryness, and the residue was dissolved with methanol-water (85:15) solution and the volume was adjusted to 1 mL, mixed well, and analyzed by liquid chromatography-mass spectrometry.

[0056] 2. Set the instrument parameters:

[0057] 1) The liquid chromatographic column adopts ZIC-cHILIC column, the specifications are col...

Embodiment 3

[0073] Embodiment 3: the mensuration of guanidine phosphate content in the foam

[0074] 1. Preparation of sample solution:

[0075] Crush the foam with a pulverizer, the size of the sample shall not exceed 2mm×2mm×2mm, mix well, put it into a clean and dry ziplock bag, and seal it for later use. Weigh 0.3g of the sample into a 40mL glass screw bottle, add 30mL of methanol-water (85︰15) solution, tighten the bottle cap and extract ultrasonically in a 60°C water bath for 60min, after cooling, take 20mL of the extract and pass through a 0.45μm PTFE organic phase Membrane filtration in a 50mL flat-bottomed flask. The solution in the flat-bottomed flask was rotary evaporated at 70°C to nearly dryness, and the residue was dissolved with methanol-water (85:15) solution and the volume was adjusted to 1 mL, mixed well, and analyzed by liquid chromatography-mass spectrometry.

[0076] 2. Set the instrument parameters:

[0077] 1) The liquid chromatographic column adopts ZIC-cHILIC c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com