Three-dimensional sampling mechanism for fully-automatic chemiluminescence instrument

An automatic chemical and three-dimensional technology, applied in the direction of instruments and analytical materials, can solve problems such as high assembly process requirements, shortened equipment service life, collision damage of sample needles, etc., achieve high equipment precision, reduce assembly and debugging workload, The effect of smooth lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

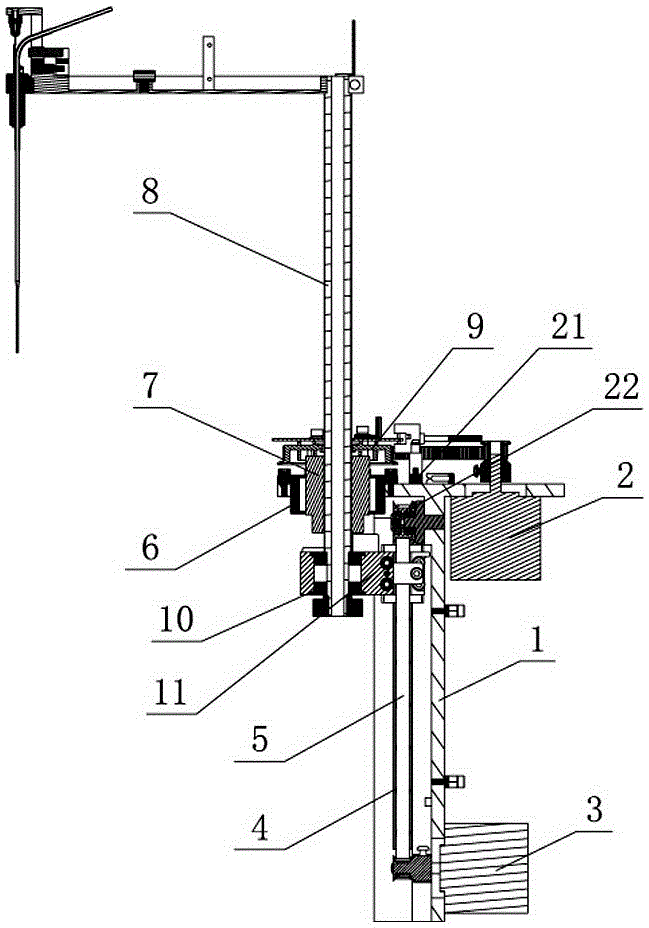

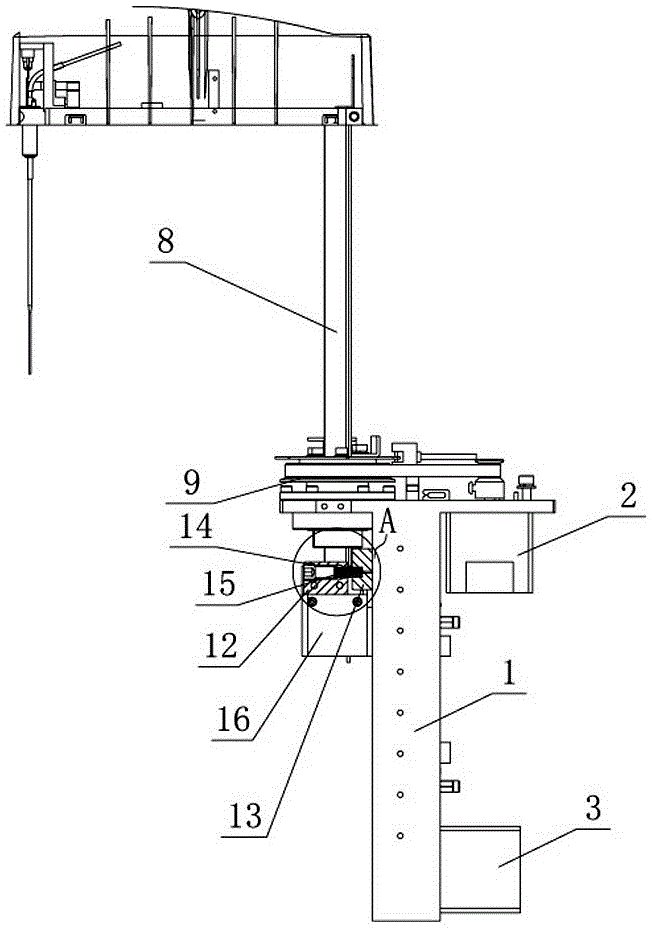

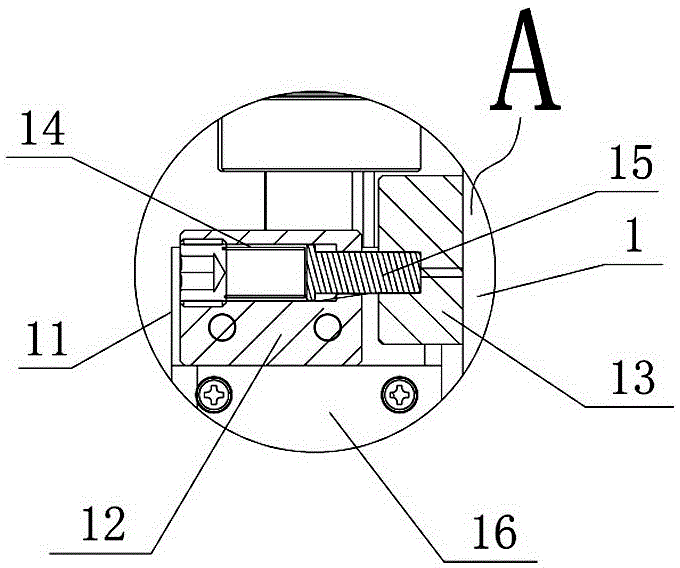

[0015] Such as Figure 1-5 As shown, the three-dimensional sampling mechanism for the automatic chemiluminescence instrument of the present invention includes a sampling arm, one end of the sampling arm is connected with the sampling needle, and the other end is connected with the flower shaft mechanism with lifting and rotating functions. The flower shaft mechanism includes a T-shaped frame 1, a rotating ball spline is vertically arranged on the left horizontal arm of the T-shaped frame 1, a rotating motor 2 is arranged on the right horizontal arm, and a lifting motor 3 and The vertical guide rail 4 positioned on the left side of the lifting motor 3 is provided with a belt 5 driven by the lifting motor 3 in parallel on the outside of the vertical guide rail 4 . Specifically, the belt 5 is a ring structure, and the T-shaped frame 1 is provided with a pulley 22 positioned above the lifting motor 3. One end of the belt 3 is connected to the motor shaft of the lifting motor 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com