A processing method for signal distortion of magnetoelectric speed sensor

A speed sensor and processing method technology, applied in the field of signal processing, can solve the problems such as waveform distortion, normal value display and deviation of the output signal of the magnetoelectric speed sensor, so as to solve the problem of signal distortion of the magnetoelectric speed sensor, short processing time, Easy to get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

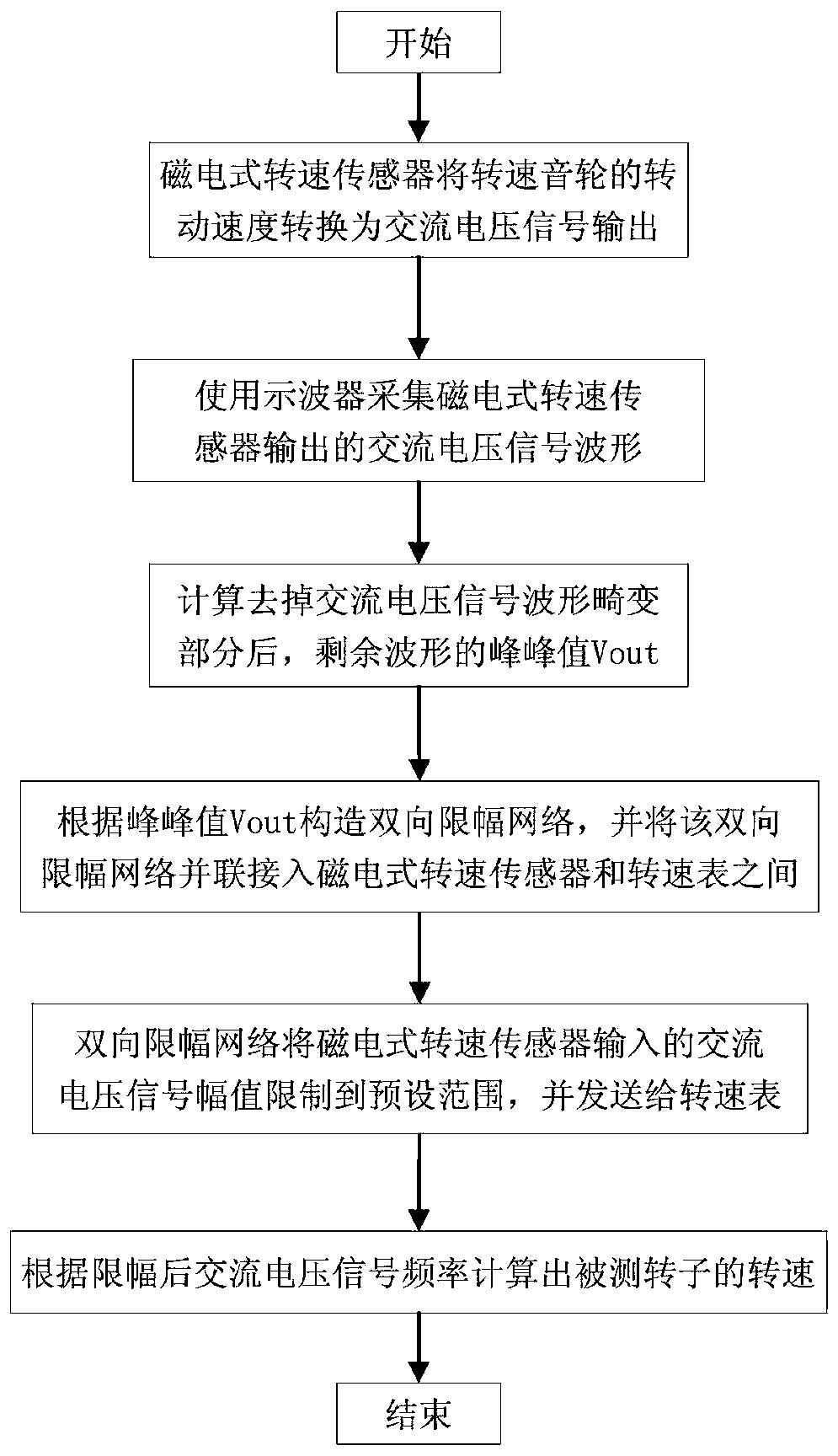

[0032] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

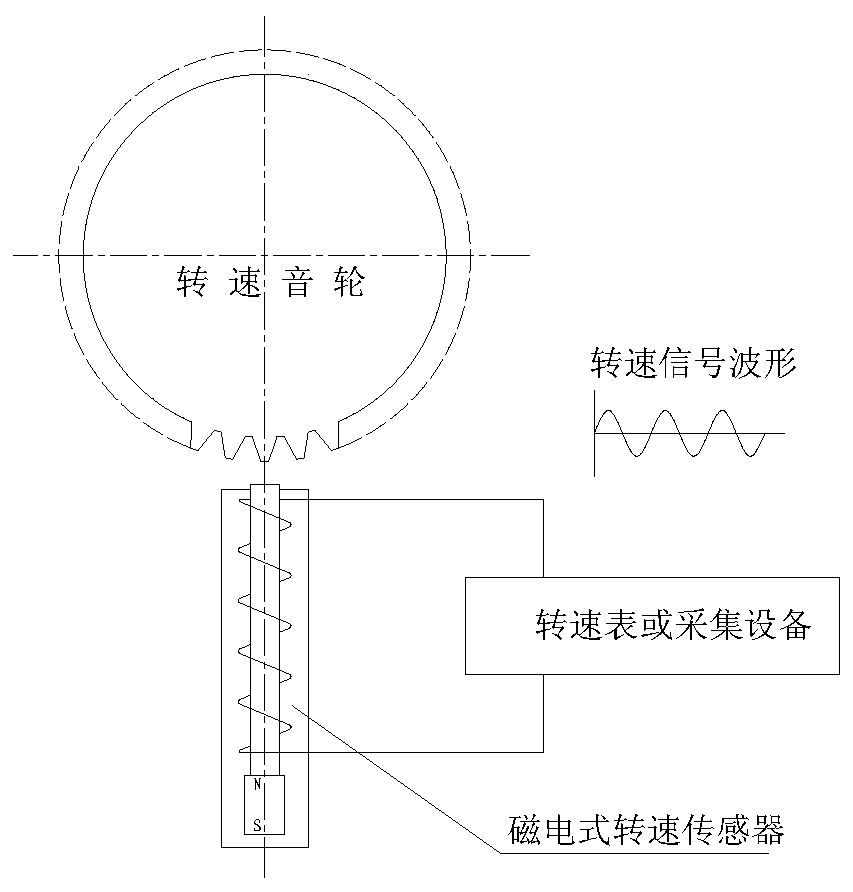

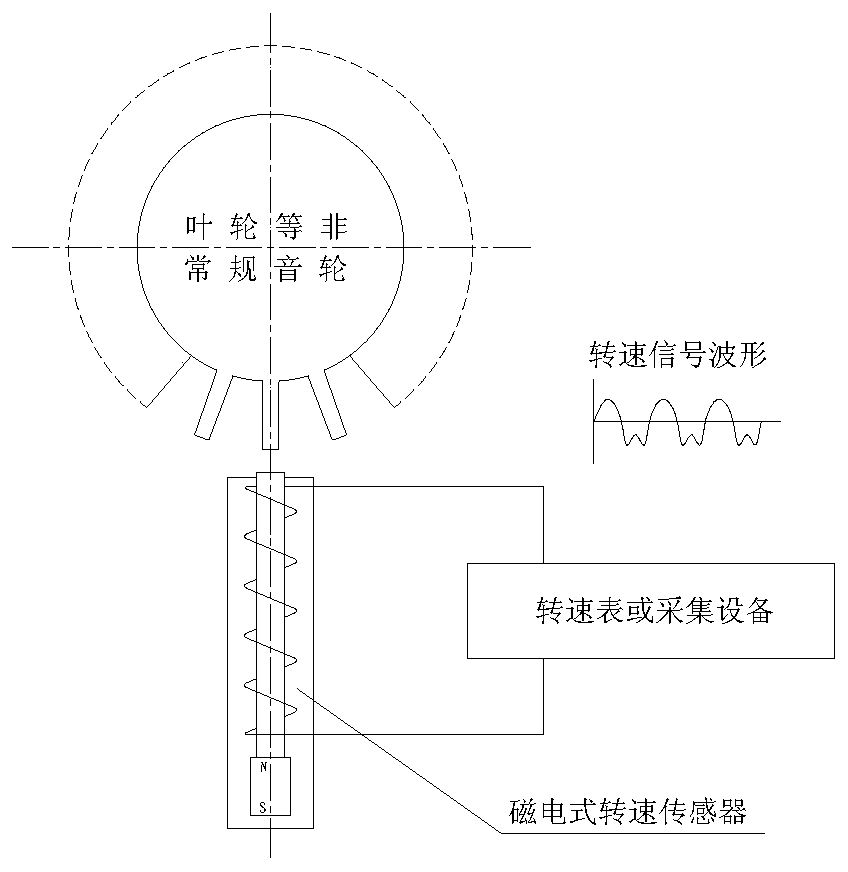

[0033] The low-pressure rotor speed measurement sensor of an aero-derivative gas turbine is installed on the cylinder (casing) at the tip of the first-stage rotor blade, and the magnetic-conductive first-stage rotor blade sweeps the magnetoelectric speed sensor and generates an AC voltage signal Output, the gas turbine control system calculates the speed of the low-pressure rotor by collecting the signal, the system is composed as follows figure 2 shown.

[0034] Because the structural shape of the low-pressure first-stage rotor blade tip of the gas turbine sweeps over the speed measurement sensor is very different from the conventional transmission gear, such as Figure 4 The signal waveform shown will cause abnormal (unstable or doubled) phenomenon in the displayed rotational speed data. The reason is that an "extra" small sine wave appears at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com