Ultra low temperature vibration sensor

A vibration sensor and ultra-low temperature technology, applied in the field of aerospace sensors, can solve problems such as no way to check, achieve a wide range of operating temperatures, improve strain capacity and transient temperature characteristics, and prevent product damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

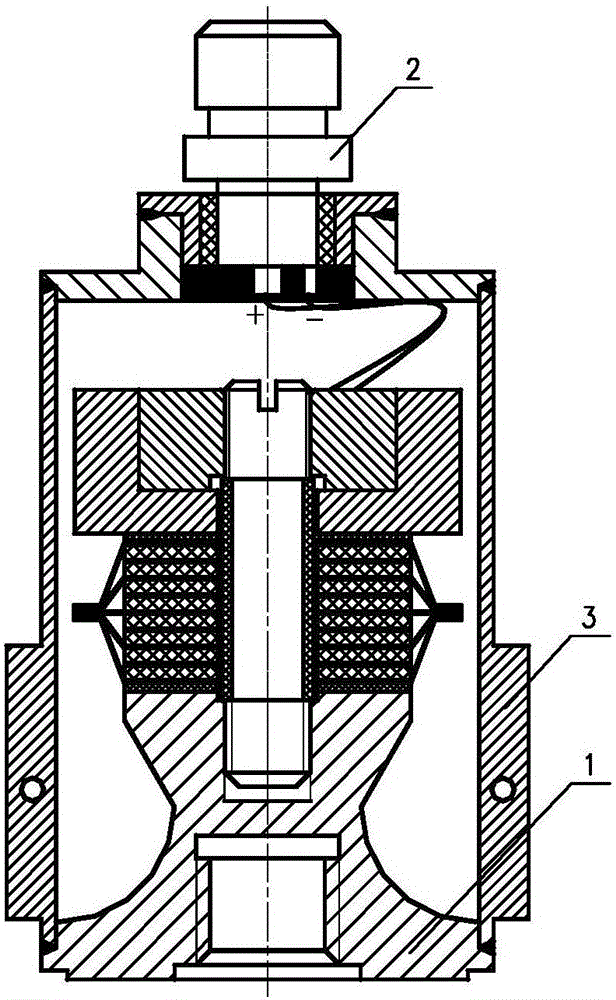

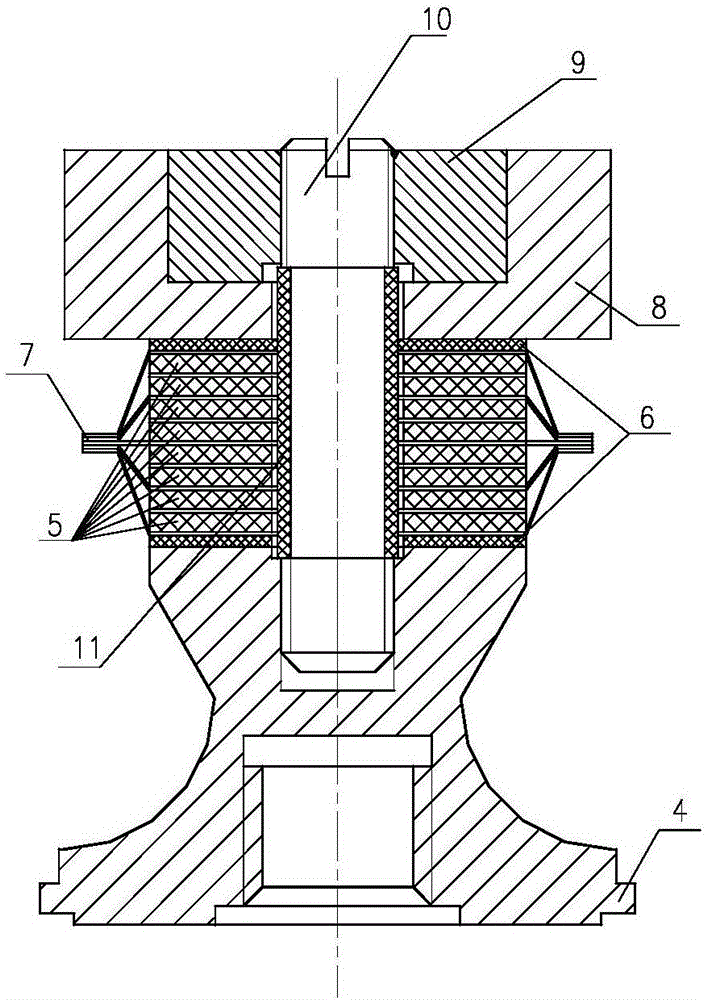

[0029] An ultra-low temperature vibration sensor belonging to the isolated base center compression piezoelectric accelerometer, such as figure 1 As shown, the sensor includes a sensitive component 1, an output assembly 2 and a housing 3;

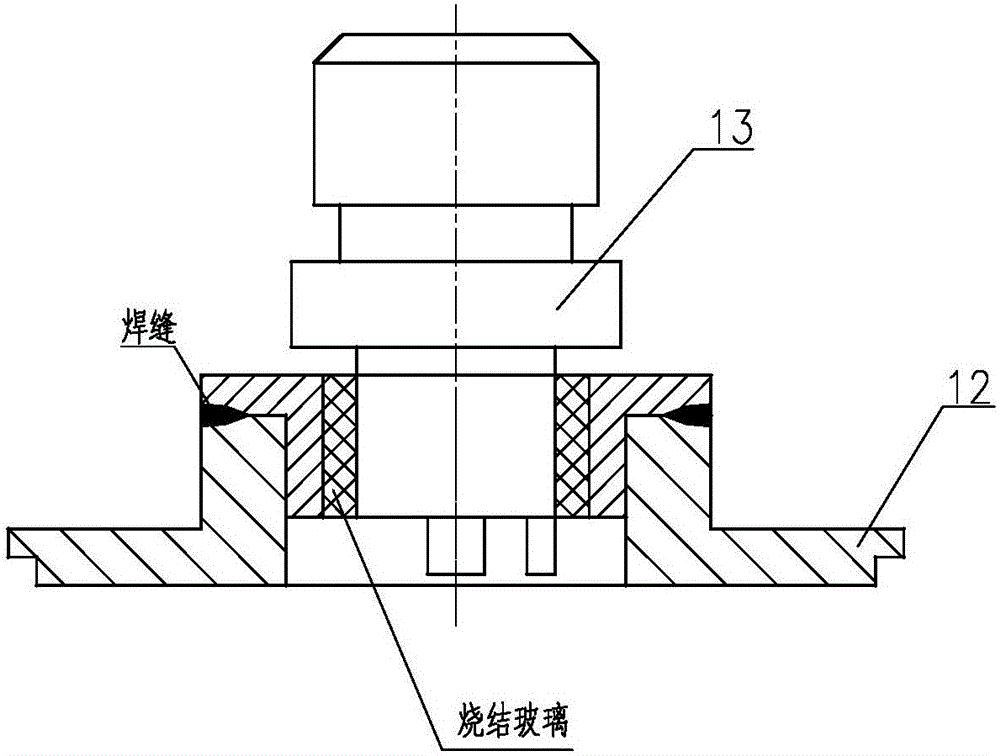

[0030] The internal electrical connections of the sensors all adopt spot welding; the housing 3 is connected to the sensitive component 1 by laser welding; the output assembly 2 is connected to the housing 3 by laser welding. The sensor of the present invention is packaged by laser welding in an inert gas atmosphere environment, so that the inside of the sensor is filled with inert gas, so as to prevent water vapor condensation in an ultra-low temperature environment from reducing the insulation resistance of the sensor.

[0031] The sensitive component 1 adopts an isolation base center compression structure, and converts the mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com