Composite jacketed metal oxide arrester with filling structure and processing method thereof

A composite jacket and processing method technology, applied in resistors, resistor parts, overvoltage protection resistors, etc., can solve the problems of easy sealing and damping of arresters, and achieve increased sealing, normal line power supply, and convenient assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

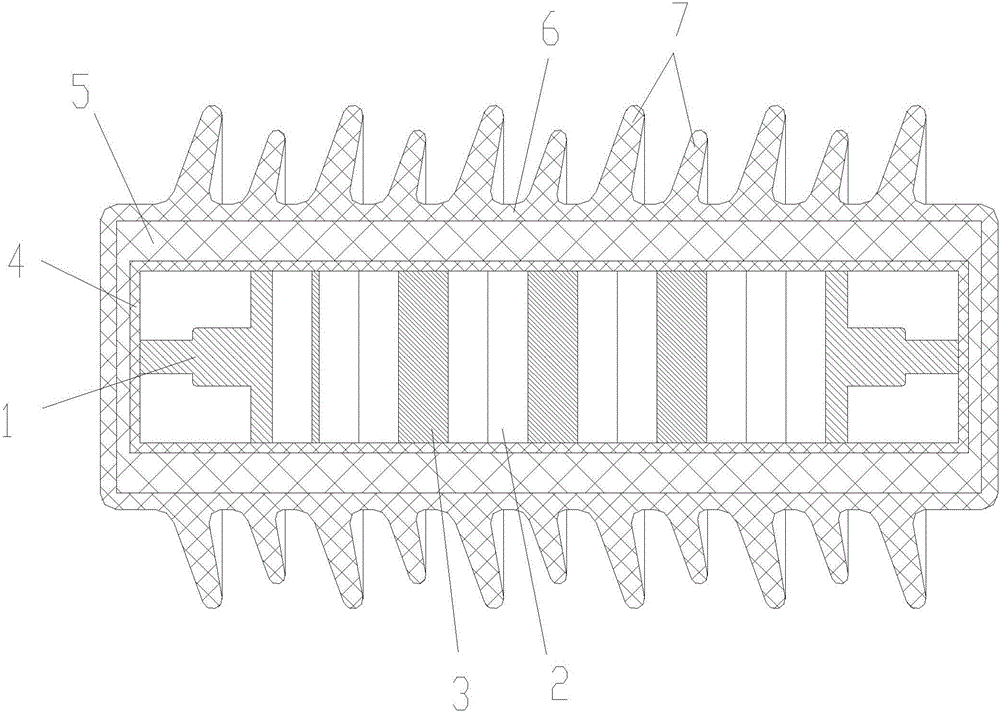

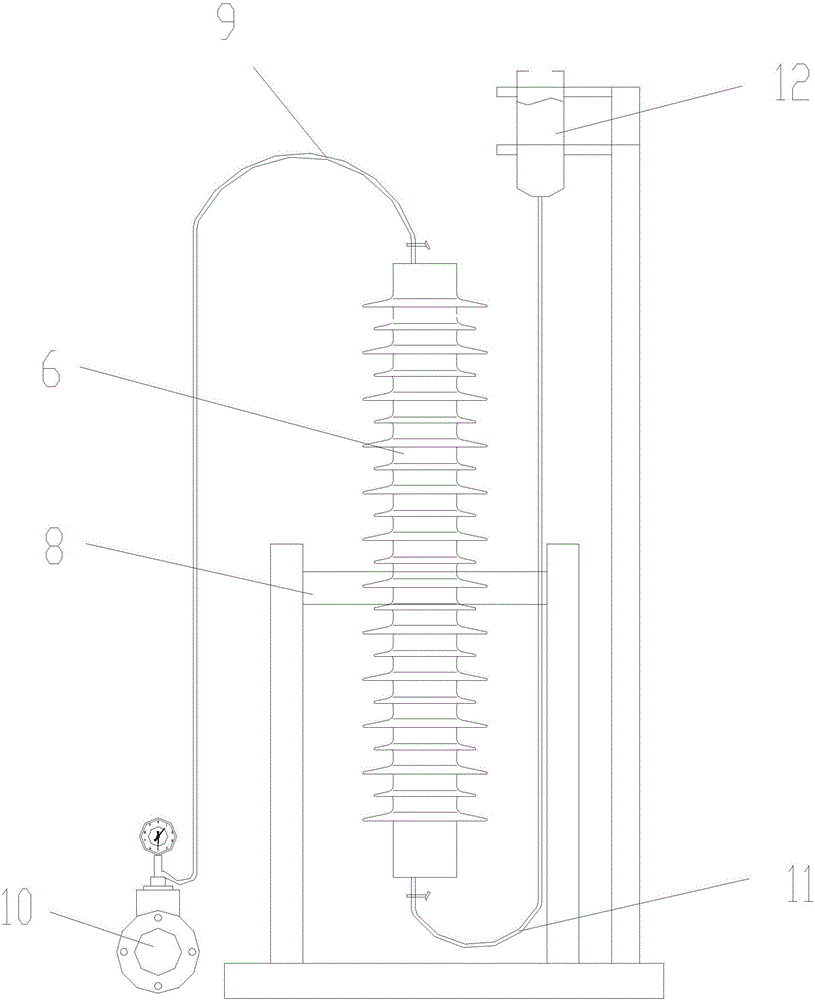

[0020] Referring to the accompanying drawings: the composite sheath-type metal oxide surge arrester with a filling structure in this embodiment includes electrodes 1 arranged at the left and right ends, and interlaced resistance sheets 2 and pads 3 are installed between the electrodes 1, and the electrodes 1 , The resistor sheet 2 and the cushion block 3 are provided with a sealed waterproof sealant 4, and the waterproof sealant 4 is provided with a heat-conducting liquid potting compound 5, and the heat-conducting liquid potting compound 5 is wrapped in the outer layer of the waterproof sealant 4, and the heat-conducting liquid is filled A silicone sleeve 6 is installed outside the sealing glue 5 . Wherein the outer side of the silicone sleeve 6 is provided with an outwardly protruding annular flange 7 . The annular flange 7 is inclined to the right.

[0021] The process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com