Packaging method for lithium ion capacitor

A packaging method and capacitor technology, which are used in the manufacture of electrolytic capacitors, hybrid capacitor terminals, and hybrid/electric double-layer capacitors, etc., can solve the potential safety hazards in strength and anti-vibration effects, difficulty in operating energy in series or parallel, and product life. Attenuation and other problems, to achieve the effect of ensuring structural strength, improving strength and seismic performance, and reducing heat generation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention provides a packaging method for a lithium ion capacitor, which will be described below with reference to the accompanying drawings.

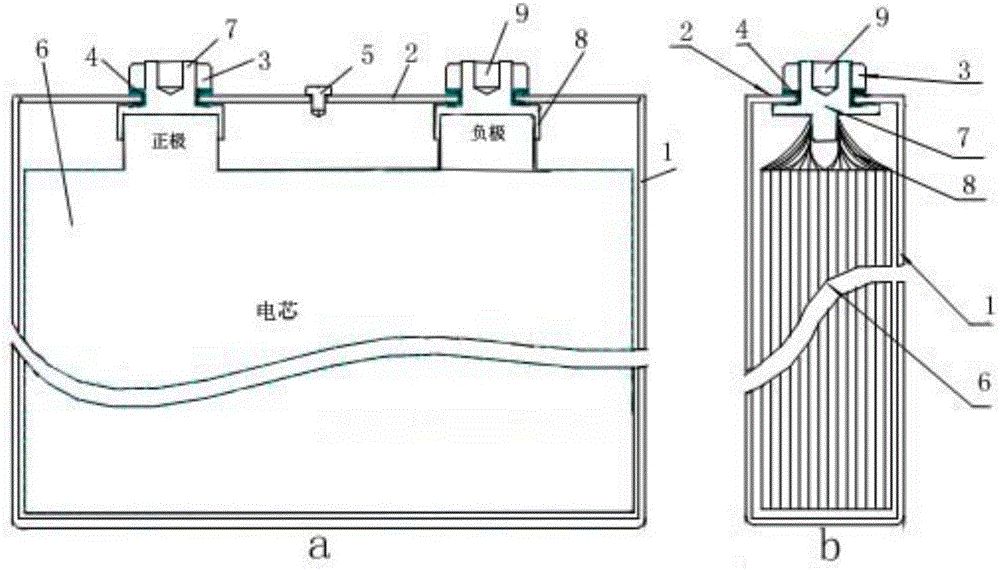

[0019] figure 1 Shown is a schematic diagram of the shell structure, figure 2 Shown is a schematic diagram of the overall lithium-ion capacitor structure,

[0020] figure 2 It is a schematic diagram of the overall lithium-ion capacitor structure; in the figure, a is a front section view; b is a cross section view. The lithium-ion capacitor is composed of a shell, a cover, a battery cell, a positive pole, a negative pole, a liquid injection hole plug and a lead-out terminal; wherein the battery cell 6 is fixed in the shell 1, and the positive pole and the negative pole of the battery cell 6 are connected to their respective electrodes through the tab 8. The lead-out terminal 7 is welded, and the central hole of the lead-out terminal 7 is a series-parallel threaded hole 9 . The lead-out terminal 7 is sealed and fixed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com