Multi-step silicon carbide groove junction termination extension structure and preparation method thereof

A junction terminal extension and termination structure technology is applied in the field of silicon carbide multi-step trench junction termination extension termination structure and its manufacture, and in the field of semiconductor device termination structure, which can solve the problem of high sensitivity of charge amount, and achieves alleviation of electric field concentration effect, The effect of increasing the curvature of the junction edge and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

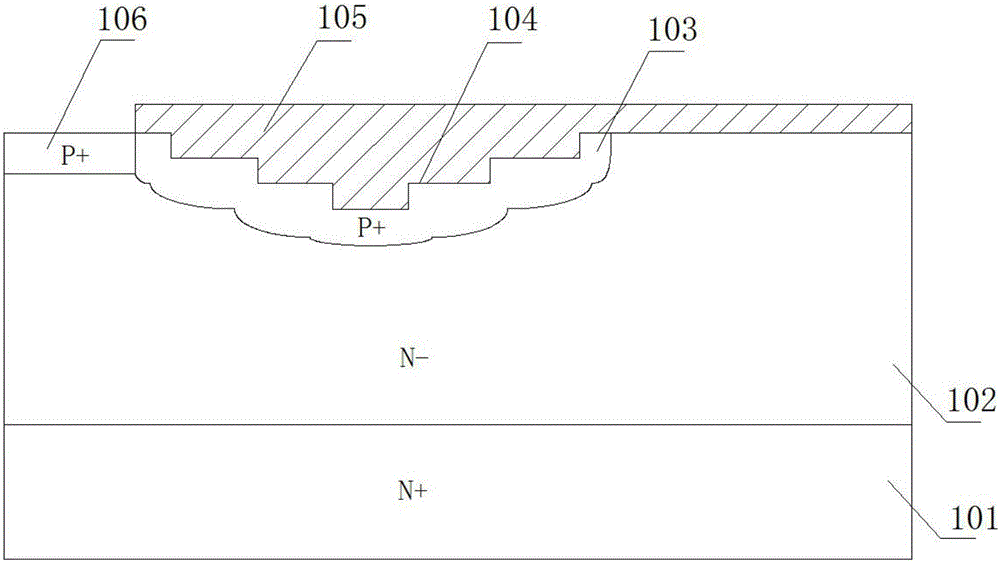

[0026] A silicon carbide multi-step trench junction terminal extension terminal structure, specifically as figure 1 As shown, it includes a silicon carbide substrate layer 101, a first semiconductor layer 102 and a passivation layer 105 stacked in sequence, wherein the silicon carbide substrate layer 101 has a doping concentration of 5×10 18 cm -3 Made of N-type SiC material with a thickness of 400 μm; the first semiconductor layer 102 is formed on the silicon carbide substrate layer 101, the first semiconductor layer 102 has the first conductivity type, and the doping concentration is 7×10 15 cm -3 , with a thickness of 10 μm; the surface of the first semiconductor layer 102 is provided with a multi-step trench structure 104, and the top of the multi-step trench structure 104 is covered with a passivation layer 105; Below the stepped trench structure 104, the junction terminal extension structure 103 has the second conductivity type. Specifically, the junction termination e...

Embodiment 2

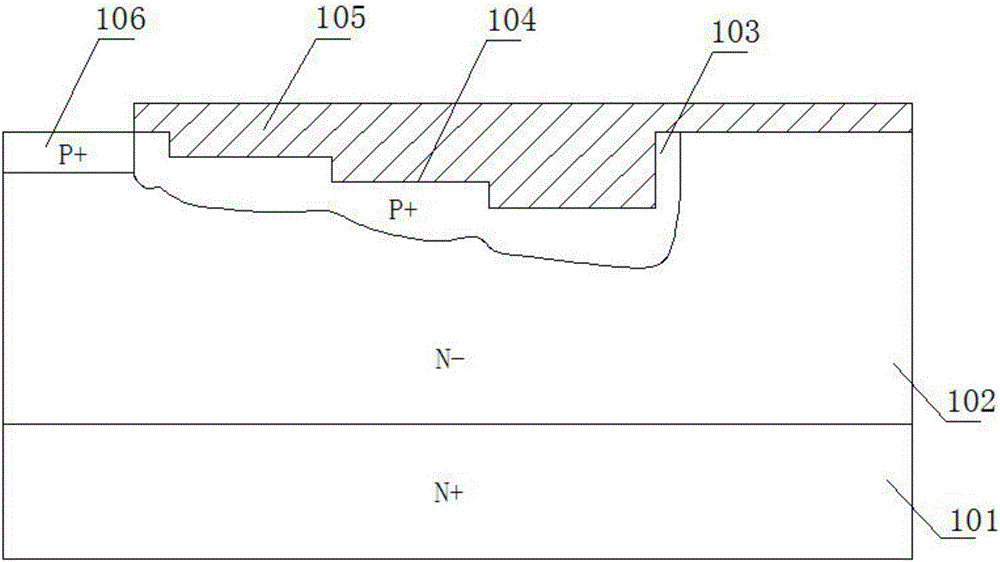

[0036] A silicon carbide multi-step trench junction terminal extension terminal structure, specifically as figure 2As shown, it includes a silicon carbide substrate layer 101, a first semiconductor layer 102 and a passivation layer 105 stacked in sequence, wherein the silicon carbide substrate layer has a doping concentration of 5×10 18 cm -3 SiC material of SiC type, with a thickness of 400 μm; the first semiconductor layer 102 is formed on the silicon carbide substrate layer 101, the first semiconductor layer 102 has the first conductivity type, and the doping concentration is 1×10 16 cm -3 , with a thickness of 5 μm; the surface of the first semiconductor layer 102 is provided with a multi-step trench structure 104, the top of the multi-step trench structure 104 is covered with a passivation layer 105, and the junction terminal extension structure 103 is arranged in the first semiconductor layer 102, and is located in multiple Below the stepped trench structure 104, the ...

Embodiment 3

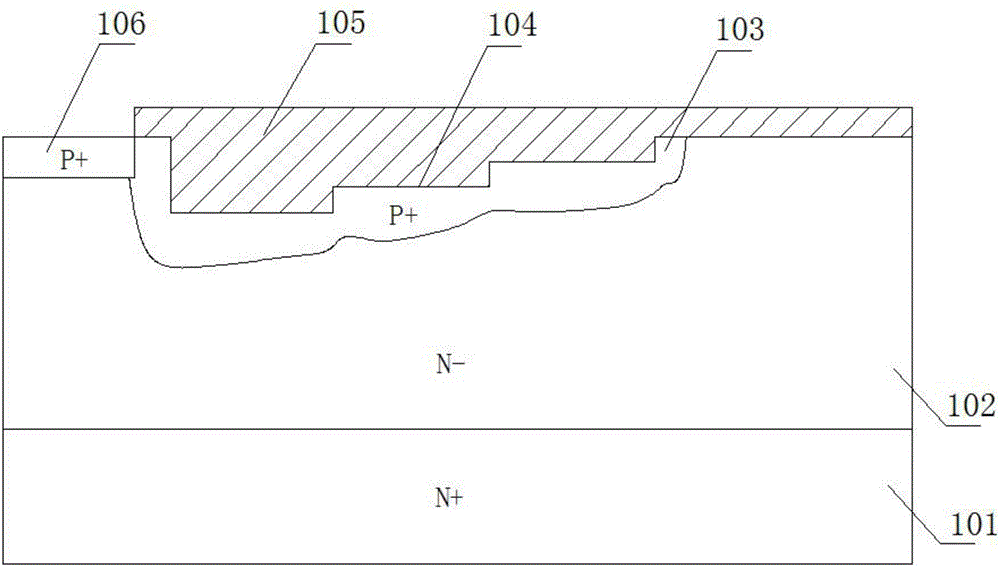

[0040] A silicon carbide multi-step trench junction terminal extension terminal structure, specifically as image 3 As shown, it includes a silicon carbide substrate layer 101, a first semiconductor layer 102 and a passivation layer 105 stacked in sequence, wherein the silicon carbide substrate layer has a doping concentration of 5×10 18 cm -3 Made of N-type SiC material with a thickness of 400 μm; the first semiconductor layer 102 is formed on the silicon carbide substrate layer 101, the first semiconductor layer 102 has the first conductivity type, and the doping concentration is 5×10 15 cm -3 , with a thickness of 15 μm; the surface of the first semiconductor layer 102 is provided with a multi-step trench structure 104, the top of the multi-step trench structure 104 is covered with a passivation layer 105, and the junction terminal extension structure 103 is arranged in the first semiconductor layer 102, and is located in multiple Below the stepped trench structure 104, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com